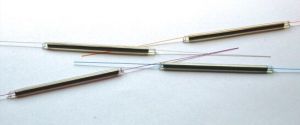

Optical Fiber Protection Sleeves

1 - 1 Per Piece

100000 Piece (MOQ)

Fiber protection sleeves, also known as splice protection sleeves, are designed to safeguard fiber optic splices from environmental factors and mechanical stress. They provide durability and help maintain signal integrity by protecting the delicate fibers during installation and operation.

Fiberglass Mosquito Mesh

4 Per Square Feet

100 Square Feet (MOQ)

Best Deals from Fiberglass Product

SMC DMC Sheets

290 - 450 Per Kilogram

20 Kilogram (MOQ)

We are reputed to be among the chief Manufacturers, Exporters, and Suppliers of SMC DMC Sheets from Uttar Pradesh, India. Our sheets are bound to surpass the expectations of our clients for being defined by the best of all attributes. Like, they are resistance to temperature and are flawlessly finished. Plus, they are dimensionally accurate and are endowed with high endurance. They are made available in an array of sizes.

fiberglass board

Get Price Quote

Fiberglass board high quality SMC DMC compounds for a variety of general as well as specialized applications to customer specifications.

Splice Protection Sleeves

Get Price Quote

The fusion spliced region of the fiber is bare glass and thus needs to be protected. Various systems designs are used to carry this out. Heat shrinkable or thermo shrinking type is the most popular method used to protect spliced fiber. It is easy, convenient and reliable method to protect bare fiber. As most splicing machines come with an oven no special tools are generally required to carry out such an installation. As the most commonly used method, familiarity with the process has become virtually universal with industry personnel.

Fiberglass Flap Disc

90 Per Piece

GLASS MICRO FIBRE SHEETS

Get Price Quote

fiberglass mesh

Get Price Quote

Fiber Glass Mesh

Get Price Quote

Carbon Fiber Sheets

Get Price Quote

Carbon fiber composite sheets are produced by compression molding method as well as vacuum infusion using carbon fiber fabric with epoxy resin, carbon fiber prepreg.In the process of compression molding, carbon fiber prepreg placed into mold, now the prepreg gets heated under pressure into mold with large hydraulic presses. Sheet gets cured as per curing cycle in varying dimensions.The Vacuum Infusion method uses vacuum pressure to inject resin into a laminate. Dry carbon fiber layers are laid into the mold and the vacuum is applied before resin is infused. Once a complete vacuum is achieved, resin is literally sucked into the carbon fiber layers.We deliver uncompromising quality and craftsmanship. Our carbon fiber sheets are consistent in quality with a superior glossy surface finish. Sheets are available in various thicknesses. Depending on the application, the sheet stiffness can be engineered using different carbon fiber layups.

Varnished Fiberglass Cloth

Get Price Quote

grp sheets

Get Price Quote

grp sheets, epoxy borewell pipes, grp rods, grp rehabilitation pipes

fiber glass tissue

Get Price Quote

fiber glass tissue, Fiber Glass, Nitrile Foam, ADHESIVE, Sealant

fiber glass reinforced plastic products

Get Price Quote

fiber glass reinforced plastic products, FRP Linings, FRP Ductings

Fiberglass Epoxy Sheets

Get Price Quote

Fiberglass Epoxy Sheets

Splice Protection Sleeves

Get Price Quote

Splice Protection Sleeves, Fiber Optic Splice

Polyfill Sheet & Fiber

Get Price Quote

Polyfill Sheet & Fiber, Shirt Interlining, microdot fusing

Fiber Glass Products

Get Price Quote

Fiber Glass Products

FiberGlass Products

Get Price Quote

FiberGlass Products

FiberGlass Products

Get Price Quote

FiberGlass Products