Wet Scrubber

Gas Neutralizing System for Air Pollution Control Device: Wet Scrubber A Wet Scrubber in the Air Pollution Control System is mandatory in India and many parts of the world. Wet Scrubber uses water to scrub clean the flue gases of any pollutant gases or particles that may remain after Bag Filtration System. The Scrubber therefore requires a pump, pipeline and a retention tank. The size of the Scrubber depends upon the capacity of the system being installed. Flue gases are introduced in the body of the Wet Scrubber from side and as they move up towards the top of the Scrubber which has the outlet, they pass through a spray of fine water droplets provided by a spray shower provided in the body. This fine spray leads to scrubbing of any pollutant in the flue gases. Cleaned gases escape through the top opening after passing through a mist eliminator whereas water with pollutants moves to the bottom of the Scrubber from where it is passed into the tank. One or more chambers of the tank allow for settling of pollutants which are then periodically cleaned and fresh water is added to make up any loss in quantity of water. It is then recalculated to the Wet Scrubber. [Note : Due to continuous up-gradation in technology, specified & projected values may differ in actual products.]

Material : Metal

Color : Metallic

Application : Industrial

...more

Venturi Scrubber

We settle the demand for Venturi Scrubbers, from anywhere across the country and abroad, with the top-of-the-line ones. Venturis are designed to remove microns creating a centrifugal action to separate liquor and contaminated particles from its tube. We are identified as the most notable Manufacturer, Exporter, and Supplier of Venturi Scrubbers from Uttar Pradesh, India. We take care of the quality aspect in an impeccable manner since the beginning of fabrication of the scrubbers. And to reassure it, we pass them through stringent quality tests.

Material : Metal

Color : Metallic

Application : Industrial

...more

Triple Stage Battery Cutting Machine

The Triple Stage Battery Cutting Machine, which we offer, is manufactured in confirmation to the established industrial standards. We are amongst the reliable Sources to source these Triple Stage Battery Cutting Machines. Also, this Triple Stage Battery Cutting Machine is manufactured using the leading-edge technology. Details This machine has an automatic conveyor Battery is placed on the conveyor Width of Battery, need not to be set It can accommodate Battery up to Max. Width of 305mm (Most of Batteries are less than this) This machine has three Blades for Cutting Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel (This wheel is visible in picture of machine) Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo, etc. will be cut and that portion ejects out from first window Second Cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed. This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining. Situated in Noida (Uttar Pradesh), we have built a wealth of reputation for manufacturing, supplying and exporting the superior-grade Triple Stage Battery Cutting Machines across the globe. Attainable at market-leading prices, the Battery Slicer (Triple Stage) is distinguished for its hassle free functions for a long span without much upkeep. For utmost gratification of the clients, we dole out quality-tested Battery Cutting Machines in tailored specifications. Specifications : Out Put Capacity : Two to Two and Half Ton/ Hour. Power Requirement : 16 Kw, 440 Volt, 3 Phases, 50 Hz. Man Power Requirement : Two no. unskilled Labor Operational Expenses for battery Breaking per ton : $ 2.10/ Ton approx Description : This Machine has One Conveyor, Three Cutting Stations with one Bend Saw Blade each. Conveyor is used to feed the batteries into machine and Cuts off batteries at three respective set heights, as set by the operator. Blades are water cooled. After Cutting operation, Cut batteries are transported out of the machine by conveyor. Cut (Sliced Off) Top of battery is ejected out automatically from first window and Connection Strap and part of Container from Second Window and third blade as stand by so during slicing off if one of the blade become blunt then another station is utilized and production is not interrupted. Other option is if Bigger battery with more height is fed then it can be sliced off into four Pieces. Maximum Height of batteries can be fed to the machine is 600 mm and width being 305 mm. Fume are collected and restricted by the Enclosed Body of Machine. No human exposure is involved in Cutting operation. Exposure of acid fumes and lead meet best environmental practices in the world No. Adjustment of Width is required. Operation of Machine : Batteries are placed on the moving conveyor. Top of Batteries is sliced off by high Speed Bend Saw. There is one Bend Saw with height adjustment to set Cutting (Slicing) Height. Height is set manually. Sliced off Lid from first window is ejected out. Then battery moves to second cutting Blade, here Connection Strap and Part of Container is Sliced off which is also ejected out from Second Window. If more height battery is sliced off then part of Plates and Container is also sliced off and Remaining Part of battery is transported by the conveyor to other end of the machine, where it is toppled into Acid Draining Attachment. Output of Machine : Battery Top Connection Strap with Container Part Part of Plates and Container Remaining part of Battery. Acid Drained out in to Acid tank.

Material : Metal

Color : Metallic

...more

Temple Furnace

We offer the Temple Furnace at the market leading. This Temple Furnace is known for its quality and long, hassle-free performance. A Mini Blast Furnace (commonly known as MandirBhatti or ShahiBhatti) is a simple, time-tested and widely used system to produce secondary lead in India and many other countries. It is the most basic of all furnaces and a production system based on this technology. About Mini Blast Furnace The Temple Furnace itself is a modified blast furnace which consists of a brick lined structure with fire brick oven in the midst and a metal Exo-skeletal structure outside. Raw material & fuel (coke) is charged manually through the side metal doors fitted in the brick structure and air is provided from the FD fans provided at the back of the brick structure. Molten metal & slag is tapped at the pits made in front of the brick structure and flue gases are sucked from the top of the brick structure which is provided with a metallic hood. Lead to be manufactured from Mini Blast Furnace is usually obtained from scrapped batteries. They are cut open or broken to segregate lead scrap, plastic and other materials from it. Lead scrap in the form of lead powder and plates etc. is charged in the furnace along with a proportionate charge of wooden coke. Thereafter the furnace is manually fired with the help of rags. FD Fan provides the necessary air required for combustion from the back of the furnace. Coke in the oven performs the functions of both, the fuel as well as a reducing agent for obtaining lead from its oxides charged in the form of lead plates & Powder. Temperature of the furnace is maintained at the desired level for approximately 30 minutes, after which molten lead along with slag flows out from the bottom of the oven into the outlet pit. Here slag is separated and molten lead is poured into Ingot Molds. To maintain this, continuous charge of raw material and coke is maintained in the furnace. This process leads to generation of flue gases which are toxic in nature and need appropriate and adequate Air Pollution Control System for their treatment. Temple furnace Is Of Two Types: Single Temple Furnace Double Temple Furnace Characteristics Low Project Capital Cost Low Energy Cost (wooden coke fired) Easy to install Easy to operate & maintain Production of low Antimony Lead (soft lead) at low temperature Generates high pollution

Material : Metal

Color : Metallic

Application : Industrial

...more

Small Battery Assembly Plant

We manufactured Small Battery Assembly Plants at competitive prices.

Color : Metallic

Application : Industrial

...more

Single Stage Battery Cutting Machine

The Single Stage Battery Cutting Machine, which we offer, is known for its sturdy make and long-life. We offer the Single Stage Battery Cutting Machine at the market leading to the clients. Low maintenance cost and ease-of-installation are the high points of these Single Stage Battery Cutting Machines. Construction : This machine has an automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set. It can accommodate Battery up to Max. Width of 305mm. Most of Batteries are below this. Cutting height can be set by turning Rotary wheel. This wheel is visible in picture of machine. Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery in machine for cutting. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Operation : Normally Cutting is set at sealing line of lid. Max. of Automotive Batteries have approximately same height, say +-10 mm. Remaining Battery will come out of machine on Conveyor. This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence, it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining. We, hailing from Noida (Uttar Pradesh, India), are the credible Manufacturer, Supplier and Exporter of the best-in-class Single Stage Battery Cutting Machines worldwide. Engineered in compliance with the industry-stated standards, the Battery Slicer (Single Station) is acclaimed for its innovative designing and never-failing function. The durability is lifted up by using graded material in the fabrication. Available in diverse specifications, these Machines are nominally priced by us. Specifications : Out Put Capacity : Two to Two and Half Ton/ Hour. Power Requirement : 6 Kw, 440 Volt, 3 Phases, 50 Hz. Man Power Requirement : Two no. unskilled Labor Operational Expenses for battery Breaking per ton : $ 1.75/ Ton approx Description : This Machine has One Conveyor, One Cutting Stations with one Bend Saw Blade. Conveyor is used to feed the batteries into machine and Cuts off batteries at required height, as set by the operator. Blade is water cooled. After Cutting operation, Cut batteries are transported out of the machine by conveyor. Cut (Sliced Off) Top of battery is ejected out automatically. Maximum Height of batteries can be fed to the machine is 600mm and width being 305mm. Fume are collected and restricted by the Enclosed Body of Machine. No human exposure is involved in Cutting operation. Exposure of acid fumes and lead meet best environmental practices in the world No. Adjustment of Width is required. Operation of Machine : Batteries are placed on the moving conveyor. Top of Batteries is sliced off by high Speed Bend Saw. There is one Bend Saw with height adjustment to set Cutting (Slicing) Height. Height is set manually. Output of Machine is one Slice of Battery Top and Remaining part of Battery. Acid Drained out in to Acid tank. Size of Machine : 2200 mm (H) X 2200 mm (B) X 3650 mm (L) Approx.

Material : Metal

Color : Metallic

...more

Rotary Furnace

Lead to be manufactured from Rotary Furnace can be obtained directly from scrapped batteries or as slag from Mini Blast Furnaces In case of former batteries are cut open or broken to segregate lead scrap, plastic and other materials from them; lead scrap in the form of lead powder/ plates etc. is charged in the furnace along with a proportionate charge of additives. In The case of latter, slag produced from Mini Blast Furnaces is charged into the Rotary Furnace, again with proportionate additives. This process is a batch type process. After filling the required quantity of raw material (either manually or mechanically), the lid of the furnace at the front is closed. The burner attached to the moving door is then fired. The Rotary Melting Furnace is very flexible and universal equipment used for recycling many non-ferrous metals. It is the major lead production technology used in India and many other countries for Secondary Lead Production. A lead production system based on this technology has certain distinct characteristics such as : Equipment scalable for installing higher capacities Recovers all lead in one production cycle Plates & powder from scrap battery as well as slag from Mini Blast Furnace can be used as raw material Requires addition of certain consumables Can be fired with various fuels Generates high Pollution both as Flue Gases & Fugitive Emissions Apart from plates and paste of lead oxide from scrap batteries, slag from Mini Blast Furnace is charged in the Rotary Furnace. In addition to these, certain compounds of sulphur are also present in the batteries. When this material is heated in the Presence of carbon, lead oxide is converted to lead. This conversion along with burning of fuel generates flue gases and fumes containing dust, dirt, oxides of lead, lead particles and such other impurities etc. Hence, to meet various goals of maintaining employees' health and factory environments as well as regulatory requirements, it becomes imperative to get high end Air Pollution Control Systems to be installed with the Rotary Furnaces.Rotary Chamber Advantages : Recovers 100% lead in the first operation. Slag produced is lead free. Equipment can be scaled up for higher production capacities. Many chemicals are required for operation. High power consumption. Rotary Furnace : We have two models of Rotary Furnace, one without barrel (Flame Shape) and another with barrel (furnace body). Both designs are advantageous, depending upon requirements. Barrel Type Rotary Furnace :This is traditional design. Smelters have been using this type of furnace from very olden days around the world. But the final product is MIXED Lead (DOGALA Lead) and the recovery is also lesser as compared to our newly designed Rotary furnace. I will explain it in next paragraph. The reason for lesser recovery is cogging of slag into the tap out hole and In this turning process molten lead is mixed with slag and small amount of lead is retraped with slag so recovery is further reduced. So we designed Rotary furnace without barrel.Rotary Furnace without Barrel or Flame Shape Rotary Furnace :In this type of furnace, following advantages had been practically gained : Barrel type Rotary was designed for Iron Smelting, not for Lead, as we all know, thermal conductivity of Iron is very much different than Lead. Iron thermal conductivity is 80 while Lead thermal conductivity is 35 W/(m K). It considerably reduces with temperature. So, we increased L/D ratio of Furnace. This reduces temp. of exit gases, hence utilisation of energy is increased.

Material : Metal

Color : Metallic

Application : Industrial

...more

Plastic Washing Machine

The crushed plastic is sent to Plastic Washing Machine through Feed Screw Conveyors to Floating Washing Machine. The plastic is washed & lead Contents sinks to the bottom of machine, the plastic is simultaneously forwarded ahead to the hot washing machine. Then the plastic is taken out with the help of Screw Conveyor from other end & put up in centrifugal de-watering machine, the washed plastic is taken out with the blowing system through Blower. The washed clean plastic is then stored in a storage bunker from there the material can be stored in bins or sacks.

Material : Metal

Color : Metallic

...more

Plastic Recycling Plant

The Plastic Recycling Plant, we offer, is set in accordance with the international standards. It stands high in quality as well as innovation. Its production capacity is ensured to be exactly the same as desired. And its efficiency surfaces from the fact that its results are flawless. We are standing amid the leading Manufacturers, Exporters, and Suppliers of Plastic Recycling Plants from Uttar Pradesh, India. This plant consists of following : Plastic crusher: it crushes plastic containers along with lid. The capacity of the machine is crushing plastics of 40 ton scrap battery in 24 hours. Electricity requirement 40 kW; manpower required one man; machine is water cooled; so, lead dust does not spread around; crushed plastics automatically fed to washing machine. Plastic washing machine: it washes plastic and separate lead dust from crushed plastic. Water is reused and lead dust/ bottom sludge can be collected from this operation. Later it can be sent be to lead furnace for recycling. Plastic rinsing machine: plastic washing machine feeds automatically to this machine with crushed and washed plastic, it rinses in water, and remaining lead dust is separated. Water pumps: two submersible pumps are used in system along with cyclone The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation. It adopts hot alkaline water washing to get good quality. Any acid or lead dust is removed by friction washing. Crushed plastic is transferred automatically by inclined material conveyor. Inclined conveyor shifts plastic pallets to rinsing machine. Rinsing machine washes again in clean alkaline water. The pH level is continuously monitored by electrical control panel. Soda ash is charged to washing tank so alkalinity is maintained. This alkaline water neutralizes acidic film formed on the surface of plastic and subsequently clean it. Man power required two men. Lead dust emissions to air is nullified due to its unique design criteria. All emissions are suppressed into water bath so no lead dust is emitted to air. So no particulate matter in the air is created. Lead dust is either transfers with water to E.T.P. Plant or settles down after de-sulphating. Battery container of 40 ton battery/ day.

Material : Metal

Color : Metallic

Application : Industrial

...more

Plastic Crushing Machine

The shaved lid which is separated from under the welded straps is sent through conveyor to Lid Crusher Machine. Plastic parts are separated from the Lead parts. Such plastic parts are sent to the Plastic Crusher & are cut into smaller pieces. This machine is used to crush Battery Container made of Plastic Material. It crushes to small Pieces up to size of 1" square in one go and Washes Lead accumulated on it. It is shearing & hammering action increases its Power versus Output Ratio. Lead is precipitate on another conveyor. This conveyor conveys Lead Particles Pieces to one side. Plastic which can float on water will be filtered on another Conveyor. Plastic is fed to Plastic Washing Machine. This Plastic Washing Machine washes Plastic with Soap Solution. Plastic is filtered and collected. Water is used again after purification.

Power : 56 H.P./42Kw.

Material : Metal

Color : Metallic

Application : Industrial

...more

Lead Refining Plant

The Lead Bullion is fed into a refining kettle. Lead bullion contains many other metallic impurities including antimony, arsenic, copper, tin and zinc. Refining Process of Lead in Detail : Removal of Copper : Copper is the first of the impurities to be removed. The lead bullion is melted at about 300–600 °C and held just above its melting-point when solid copper rises to the surface and is skimmed off. Sulfur is stirred into the melt to facilitate the operation by producing a dry powdery dross which is more readily removed. Once copper has been removed, there are a number of processes available for the extraction of the other impurities from the bullion. These include, in which elements are removed one or more at a time in several stages. Removal of antimony, arsenic and tin : After the removal of copper, the next step is to remove antimony, arsenic and tin. There are two methods available — the softening process (so-called since these elementsare standard hardeners for lead) and the Harris process. In the softening process, the lead bullion is melted and agitated with an air blast, causing preferential oxidation of the impurities which are then skimmed off as a molten slag. In the Harris process, the molten bullion is stirred with a flux of molten sodium hydroxide and sodium nitrate or anothersuitable oxidizing agent. The oxidized impurities are suspended in the alkali flux in theform of sodium antimonate, arsenate and stannate, and any zinc is removed in the form of zinc oxide. Removal of silver, gold & Bismuth : After the removal of antimony, arsenic and tin, the softened lead may still containsilver and gold, and bismuth. The removal of the precious metals by the Parkesprocess is based on the fact that they are more soluble in zinc than in lead. In this process,the lead is melted and mixed with zinc at 480 °C. The temperature of the melt is graduallylowered to below 419.5 °C, at which point the zinc (now containing nearly all the silverand gold) begins to solidify as a crust on the surface of the lead and can be skimmed off.An alternative procedure, the Port Pirie process, used at the Port Pirie refinery in Australia,is based on similar metallurgical principles. Removal of zinc : The removal of the precious metals leaves zinc as the main contaminant of the lead.It is removed either by oxidation with gaseous chlorine or by vacuum distillation. Thelatter process involves melting the lead in a large kettle covered with a water-cooled lidunder vacuum. The zinc distils from the lead under the combined influence of temperatureand reduced pressure and condenses on the underside of the cold lid.Refined lead is poured into moulds and ingots are formed. These ingots are then sent to storage. For integrated Production of Lead Oxide, Refined Lead is casted into Balls. (to be fed directly to Lead oxide Ball Mill). About Lead Refining : Lead recycled from used lead acid batteries or other sources (Secondary Smelting) via the Mini Blast Furnace or Rotary Furnace route, contains lot of contamination and undesired components. On the other hand, Lead required for battery manufacturing is either soft Lead with 99.97% purity or hard Lead of varying Antimony compositions.In order to make quality of lead suitable for its different uses,different variations of pot melting processes are employed. These includes : “Re-Melting” for removal of slag, “Refining” for attaining required purity levels and “Alloying” for producing various alloys of lead. The equipment used is the same, the consumables and the processes, however, differ. Refining Pot Details : The Refining Pot (or Refining Kettle or Alloying Pot, as it is variously called), is a mechanical mixing device with a pot and a heating arrangement. The inner pot is made of heavy MS plate with dish end bottom. It is placed within a jacket of refractory bricks, which in turn, are protected by an outer cover of MS plate with reinforcements. The pot is covered at the top with opening for feeding lead ingots and is provided with an electro-mechanical mixer. At the bottom, a heating source, usually an oil fired/ Diesel burner& sometimes by Wood burning is provided to heat the pot and to melt the lead. Once lead melts, impurities are skimmed and removed and any consumables required are added. Lead is then drained from the pot through an outlet pipe and valve. Capacity of such pots depends upon the requirements of particular units. Standard pot capacities made are from 3.0 Tons per Batch to20.0 Tons per Batch. Higher capacity pots are also manufactured as required by any particular establishment. Melting pots are installed both with and without accessories which may include Ingot Casting Machine, Ball Making Machine (where Ball Mills are installed down the line), Air Pollution Control Systems, Jib Cranes etc.Production Process :Melting Processes have been grouped as Re-Melting Process Refining Process Alloying Process Re-Melting Process : This process is undertaken for value addition to the recycled lead from furnaces. Lead is melted in the pot and major impurities are skimmed from it to make it saleable in the market.Refining Process : Lead is melted in the pot, additives such as Sulphur, Wooden Powder and Coke Breeze are added and mixed gently followed by dross removal. Thereafter, Tin is added to remove Copper and temperature is increased to 550-6000C. Further, additives such as Sodium Nitrate & Caustic Soda are added to remove Antimony. This process is repeated to get the desired purity of lead. Alloying Process : Lead is melted in the pot; additives such as Sulphur, Wooden Powder & Coke Breeze are added and mixed gently followed bydross removal. Thereafter, Tin & Antimony are added to the liquid metal to get the desired grade of Lead.Melting processes lead to generation of air pollution at the following stages : Initial heating and melting generates fumes Drossing with sulphur, wooden powder and coke breeze generates lot of smoke and dust particles Further heating for Refining and Alloying with different chemicals generates fumes and dust particles. Hence, to meet various goals of maintaining employees' health, factory environments as well as regulatory requirements, it becomes imperative to get high end Air Pollution Control Systems to be installed with the Melting Pots.Characteristics of Air Pollution generated in Melting Pot : Dust : 500-600 mg/Nm3 Temperature : 60-80° C Gases : Fumes and Dust Discharge Characteristics required as per Norms : Dust - Less than 50 mg/Nm3 Lead ( Pb) - Less than 10 mg/Nm3 Temperature - 50-60° C Gases - Not Detectable Selection & Detailson Technology for Air Pollution Control : Based on the Parameters and the Standards mentioned, the following technology is adopted for Air Pollution Control Systemin Melting Pot is Pulse Jet based Bag House Filtration System

Color : Metallic

Application : Industrial

...more

Lead Refining Kettle

Buy corrosion resistant and highly durable Lead Refining Kettles from us as per requirements. We offer them in varied designs, styles and sizes to cater to varied demands of buyers. Our company is ranked among responsive and responsible Manufacturers, Exporters and Suppliers of a comprehensive assortment of Lead Refining Kettles. They function optimally and guarantee long service life. Known For Easy to maintain Long-life Hassle-free performance Low power consumption Stirrer and how it function? : Propeller type Stirrer transform Electrical torque into centrifugal force to dispersion and emulsification force depends upon R.P.M. Resonance is created in case of refining dispersion of metal is produced which separates metal according to its density, so vessel height, diameter of impeller and no. of impeller is important factor. But for alloying of metal with other metal, emulsification is created by changing R.P.M. and diameter of Vessel. Fluid-O-Matic Alloying Pot : No. of Stirrer are increased to two and aerofoil design is incorporated. No. of Blade are three. Distance of stirrer from bottom is more compare to refining pot. Thicker Shaft is used and balanced dynamically so in case of lesser fluidity due lesser temperature it resists unwanted forces. Surface Area is increased by mounting extra fins all around the pot. So transmission of heat is vertically transfers through fins to the pot and extra fins give more contact area with flame and flue gases at one end another is welded with the vessel so transmission is faster in conduction than radiation medium. This effects in transmitting heat to the molten lead because with the increase in temperature conductivity of heat is reduced in lead. Heat transmission is increased so pot itself does resists its oxidation/ burning/combustion. Due to lesser temperature difference from inner surface to outer surface. Difference of Temperature form bottom to top layer of metal is reduced. More thickness is used which also assists in heat storage and transmission of heat. Above all it gives longevity, increases performance, increases durability of the pot. Emulsification of metals is required in alloying. It is very much important , so stirring is done accordingly. So. By summarizing above facts, Fluid-O-Matic Alloying Pot gives better Alloying of Lead with other metals. Better return, Lesser consumption of fuel which are coupled with Better design of Burner made us. Fluid-O-Matic Refining Pot Depth of Vessel divided by Diameter of Vessel should be equal to one or more so it depend upon size of Batch. No. of Stirrer are increased to two and aerofoil design is incorporated. No. of Blade are three. Distance of stirrer from bottom is less compare to Alloying pot so better lifting of impurities to the top. Thicker Shaft is used and balanced dynamically, so during lesser fluidity due lesser temperature, it resists unwanted forces. Surface Area is increased by mounting extra fins all around the pot. So transmission of heat is vertically transfers through fins to the pot and extra fins give more contact area with flame and flue gases at one end another is welded with the vessel so transmission is faster in conduction than radiation medium. This effects in transmitting heat to the molten lead because with the increase in temperature conductivity of heat is reduced in lead. Heat transmission is increased so pot itself does resists its oxidation/ burning/combustion. Due to lesser temperature difference from inner surface to outer surface. Difference of Temperature form bottom to top layer of metal is reduced. More thickness is used which also assists in heat storage and transmission of heat . Above all it gives longevity, increases performance, increases durability of the pot. Dispersion of metals is required in refining. It is very much important , so stirring is done accordingly. So. By summarizing above facts, Fluid-O-Matic Alloying Pot gives better Refining of Lead. Better return, Lesser consumption of fuel which are coupled with Better design of Burner made us. Standard Refining Kettle - It Consistes of following : Shell with Material Pouring Valve. Single Stirer with triplex Blades. Driven Pulley Drive Motor with Pulley Suitable V- Belts Mounting Stand for Stirrer V-Belt Tension Adjustment Systems Motor Panel with Motor Starter ( Star- Delta Starter) and Temperature Indicator. V-Belt Guard Other Required Accessories : Burner Refractory Fire Bricks Insulation Bricks Hood for Pollution Contol Measures Pollution Control Unit Plateform Suitable Casting System i.e. Tundish, Ingot Casting Machine, ball Casting Machine Ingot Casting Moulds Jumbo Casting Moulds Fuel Tank Fuel Filtration System Brick Protective Cover Burner for Refining Kettle : Our Buners are used for best fuel economy. These are known for their durabilty and non stop performance. These are fitted with aerodynamically balanced blower with Suntac Fuel Pump. This pump is internal gear pump which gives non clogging service which is enhenced by its positive dispalacement feature. Positive displacement pumps are used to give high prssure which helps to automize better. Smaller oil droplets are created by more pressure so smaller droplets have more surface are to reacts with Oxygen in the air which gives smokeless combustion of fuel. Air Fuel ratio is factory set and training is also provided to set Air Fuel Ratio of Burner. Internationally acclaimed Oil Nozzles from Danfoss or Delavan, are used to give unteruppted flow of fine oil drollets spray, are fitted in our Burners. Many options are available which will depend upon Requirement of capacity, Fuel option Available. Single Stage Burners are normally used for Smaller size of refining Kettles. i.e. 2 Ton to 10 ton. Double Stage Burners are used for Bigger Capacity size of Kettle i.e. 20 Ton to 50 Ton. Duel Fuel Burners are used for Much Bigger Capacity. Fuel Options available are LDO, HSD, Gas CNG/PNG, Furnace Oil etc. Spares are also available are burners. Emmision from Refining Process : Lead Fume will be created during melting and Stiring Operation due to evaporation of Lead. Sulphur Diaoxide will generate during Copper Removal. Zinc Fume will be generated during process of Silver Extraction. Antimony TriOxide Fumes will be generated during antimony Removal Process. Carbon Dioxide from Fuel combustion in the burner. Alloying and Refining Plant with following : Hood and Slidable lid Refractory Brick Burner Plateform Pollution Control Unit Dross Collection Bin with Bottom unloading Burner

Material : Metal

Color : Metallic

...more

Lead Recycling Plant

The battery-recycling has changed dramatically over the past ten to twenty years. The changes have resulted from environmental regulation, changes in battery-processing technology, changes in battery distribution and sales techniques, changes in lead-smelting technology, and changes in the lead alloys used in the batteries.

Color : Metallic

...more

Inter Partition Welding Machine

Material : Metal

Induced Draft Blower

We work in an absolute adherence to quality norms to serve the global market with high-quality Induced Draft Blowers. We are associated with the league of #1 Manufacturers, Exporters, and Suppliers of Induced Draft Blowers from Uttar Pradesh, India. The blowers, we offer, are appreciated for high performance. They are durable, qualitative, and are made in a way to withstand the test of time. Details :Flow air/ flue gases out of Furnace to Stack. So some force is required to move flue gases through the Settling Chamber, Cyclones, Cooling Lines and bag house. This force is induced by the Blower on flue gases. Blowers/ Fans exert a pressure to move air (or gases) against a resistance caused by ducts, dampers, or other system components in a gas flow system. The fan/blower rotor/impeller receives torque from a rotating shaft of electric motor or some other driver. Impeller of fan/blower forces gases through the system.As RPM is increased for more flow, power is increased cubically whereas if diameter is increased then power is only doubled, so bigger size of blower is more useful at lesser RPM than smaller size blower at more RPM. Basic requirements for Blower are following : Air Volume, this depends upon fuel consumption in the system and required pressure in the furnace Drive type, Direct driven / indirect driven / Direct coupled Operating Temperature Blower RPM will make less/ more Motor H.P. Construction material, depends upon flue gas

Material : Metal

Color : Metallic

Application : Industrial

Drive Type : Electric

...more

Hole Punching Machine (Single Hole in One Go)

Application : This machine punches Single hole at a time in partition of container. Machine is Pneumatically powered. Different size of hole can be done with the help of different die for different size of batteries. Three Dies will make five sizes of batteries. Operation : Place the container in upside down position to fit required slot. To punch five holes, five Operations are required to be repeated. Different die is required to suit different size of battery Container.

Material : Metal

Application : Industrial

...more

Heat Sealing Fixtures

Surface Finishing : Polished

Material : Metal

Color : Metallic

Application : Industrial

...more

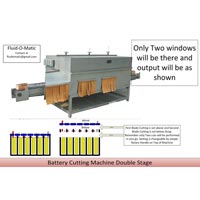

Double Stage Battery Cutting Machine

We offer the clients premium Double Stage Battery Cutting Machine at the best. Also, these Double Stage Battery Cutting Machines are manufactured in confirmation to the defined industrial standards. We are among the trusted sources to procure these Double Stage Battery Cutting Machines. Construction : This machine has an automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set. It can accommodate Battery up to Max. Width of 305mm. Most of Batteries are below this. This machine has two Blades for Cutting. Cutting heights of both the blades can be set at independent height by turning Rotary wheel. This wheel is visible in picture of machine. Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First cutting is set normally at sealing line of lid and Second cutting is set below strap. Operations : During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Maximum of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed. This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank. This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining.

Material : Metal

Color : Metallic

...more

Conveyorised Acid Draining Machine

Once Battery is cut and now only Plates with separator are there in Plastic container. There may be acid in the Battery Container still. Battery will drop in upside position, manually assisted. Container can be picked up and placed at a side or drop in Plastic Crusher. Battery Plates and Separator can be transported to Plate Crushing Machine. Acid will drop in tank. Acid Proof Tank is in-built in the attachment. Lead Oxide Dust and small grid parts will precipitate. Acid can be pumped out, if connected to another tank. Lead Sludge can be charged in furnace.

Color : Metallic

...more

Battery Recycling Machines

WE PROVIDE FULL TURN KEY PROJECT FOR LEAD RECYCLING PLANT INCLUDING FROM SHED MAKING, PLANT SETUP, ERRECTION INSTALLATIONS, TRAINING, MANPOWER, TECHNICAL SUPPORT, CONULTANCY, AFTER WARRANTY SERVICES, AMC CONTRACTS WORLDWIDE, PLANT CARE TAKING, WE HAVE PLANT FOR 2MT LEAD PRODUCTION TO 100MT PRODUCTION PER DAY.

Color : Metallic

Application : Industrial

...more

Battery Making Machines

we provide full turn key solution for battery making project, we have plants for making 10 battery a day to 1000 battery a day. we train, install & provide manpower for running the plant,

Material : Metal

Color : Metallic

...more

Battery Cutting Machine

This machine has a automatic conveyor. Battery is placed on the conveyor. Width of Battery, need not to be set. It can accommodate Battery up to Max. Width of 305mm. Most of Batteries are below this. Cutting height can be set by turning Rotary wheel. This wheel is visible in picture of machine. Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery in machine for cutting. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Normally Cutting is set at sealing line of lid. Max. of Automotive Batteries have approximately same height, say +-10 mm. Remaining Battery will come out of machine on Conveyor.

Material : Metal

Color : Metallic

...more

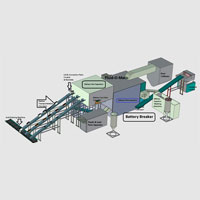

Battery Breaking Plant

We are counted among one of the leading Manufacturers and Exporters of a wide range of Battery Breaking Plants. Designed and fabricated using the latest CAD/ CAM technologies and premium raw materials, our entire range of Battery Breaking Plant is reliable and highly efficient. Our team of experienced engineers enables us to construct high performance Battery Breaking Plants that are easy to assemble, commission, operate and manage. The range of Battery Dismantling & Separation Units we have are designed for different capacity, investment and labor deployment. They are mentioned as follows : Battery Crusher ( Mini) useful for small units Battery Cutting Machine useful for small units Battery Slicer ( Available in three configuration) useful for Medium Scale units Battery Crusher useful for Bigger units The system is controlled through Control panels [PLC operated unit integrated]. The plant has individual operational control system on feed conveyors also for operators. A master control panel is attached in the Main Control Room as provided by the customer nearby the plant. The Plant has additional feature of Auto Shut Down with the Self Fault Facing Indication displays. These displays can be fixed up as per the custome defined position within Five meter range. This helps in knowing the actual position of the plant & reduces the lead time period to search for the errors & with faster production. Construction & Structure The Breaking system is built exclusively of SS steel grade 306,310(as pe availability), & the Acid Proof Plastic Coating is done on certain parts which indirectly come into the contact of Acid; Stainless steel assures trouble free operation and increased durability. These classification units, are designed as complete system, it provide low initial cost with high efficiency. The system also offers low maintenance, easy installation and start up, low power consumption and water consumption is only for Floatation process in separating Lead & Lid Parts, this water is filtrated and reused with the same up to its fullest and later on, it can be re used in making balls of Oxide dust for feeding in Oxide mills. Features Systems are useful for small or large capacity operations. SS Steel is used in plant & Special Acid Proof Plastic Coating at some parts is done to keep the cost to minimum & for plant�s durability. High level of automation with the PLC units is there for auto Controlling & Self Fault Indication display. Auto Shut down of Plant for facing any errors increase plants life & ensures safety. Low Power Consumption. Machines are completely enclosed for making it environment friendly & reducing Material Wastages. Machine is Rugged & Heavy Duty. It is capable of running for 18-21 Hrs. continuously. Benefits Low labor costs. 99%+ Lead yield. Low energy costs. Environment Friendly. Low maintenance costs. Saves Warehousing Costs. Reduced processing cost per ton. Simplified environmental compliance. Reduces the market DEMAND-SUPPLY Gap. Helps in maintaining & keeping costs of Raw Material

Material : Metal

Color : Metallic

...more

BAP Plant

1,000,000 Per Set

This machine is used for making new batteries . It is used to make all kinds of batteries like car battery, inverter battery, solar battery, UPS battery, E-Rickshaw type battery. The machine is heavily built to produce minimum 50 batteries to 600 batteries per day depending upon the selection of plant model. It is a user friendly machinery and has a plug n play type process. Any layman can be trained on machine within a day for operations on the machine. We provide technical training, guidances, trouble shooting training, User manuals in both print & video manuals so that even an illiterate can easily find out the problem while seeing the video of machines. Along with this, our machines has self fault finding technology that itself identifies its problem and indicates the operator so that the rectifying steps can be taken very early. This helps our customers in getting themself as engineers for their machinery.

Surface Finishing : Polished

Material : Metal

Color : Metallic

Application : Industrial

...moreOpening Hours