Rotary Furnace

Get Price Quote

Lead to be manufactured from Rotary Furnace can be obtained directly from scrapped batteries or as slag from Mini Blast Furnaces In case of former batteries are cut open or broken to segregate lead scrap, plastic and other materials from them; lead scrap in the form of lead powder/ plates etc. is charged in the furnace along with a proportionate charge of additives. In The case of latter, slag produced from Mini Blast Furnaces is charged into the Rotary Furnace, again with proportionate additives. This process is a batch type process. After filling the required quantity of raw material (either manually or mechanically), the lid of the furnace at the front is closed. The burner attached to the moving door is then fired. The Rotary Melting Furnace is very flexible and universal equipment used for recycling many non-ferrous metals. It is the major lead production technology used in India and many other countries for Secondary Lead Production. A lead production system based on this technology has certain distinct characteristics such as : Equipment scalable for installing higher capacities Recovers all lead in one production cycle Plates & powder from scrap battery as well as slag from Mini Blast Furnace can be used as raw material Requires addition of certain consumables Can be fired with various fuels Generates high Pollution both as Flue Gases & Fugitive Emissions Apart from plates and paste of lead oxide from scrap batteries, slag from Mini Blast Furnace is charged in the Rotary Furnace. In addition to these, certain compounds of sulphur are also present in the batteries. When this material is heated in the Presence of carbon, lead oxide is converted to lead. This conversion along with burning of fuel generates flue gases and fumes containing dust, dirt, oxides of lead, lead particles and such other impurities etc. Hence, to meet various goals of maintaining employees' health and factory environments as well as regulatory requirements, it becomes imperative to get high end Air Pollution Control Systems to be installed with the Rotary Furnaces.Rotary Chamber Advantages : Recovers 100% lead in the first operation. Slag produced is lead free. Equipment can be scaled up for higher production capacities. Many chemicals are required for operation. High power consumption. Rotary Furnace : We have two models of Rotary Furnace, one without barrel (Flame Shape) and another with barrel (furnace body). Both designs are advantageous, depending upon requirements. Barrel Type Rotary Furnace :This is traditional design. Smelters have been using this type of furnace from very olden days around the world. But the final product is MIXED Lead (DOGALA Lead) and the recovery is also lesser as compared to our newly designed Rotary furnace. I will explain it in next paragraph. The reason for lesser recovery is cogging of slag into the tap out hole and In this turning process molten lead is mixed with slag and small amount of lead is retraped with slag so recovery is further reduced. So we designed Rotary furnace without barrel.Rotary Furnace without Barrel or Flame Shape Rotary Furnace :In this type of furnace, following advantages had been practically gained : Barrel type Rotary was designed for Iron Smelting, not for Lead, as we all know, thermal conductivity of Iron is very much different than Lead. Iron thermal conductivity is 80 while Lead thermal conductivity is 35 W/(m K). It considerably reduces with temperature. So, we increased L/D ratio of Furnace. This reduces temp. of exit gases, hence utilisation of energy is increased.

Muffle Furnace

Get Price Quote

1 Piece (MOQ)

Best Deals from Furnaces

Muffle Furnace

Get Price Quote

JLS India is a leading Indian manufacturer of muffle furnaces for laboratory use with temperature range 800°C to 1800°C. As required, we provide both readymade (ready stock) and customized muffle furnace systems to our customers worldwide. These laboratory muffle furnace and Tube furnace units are utilized in general purpose heating in laboratories, ashing tests on wool, rubber, fibers or fabrics, heat treatment requirements for gears and various research facilities in chemistry and physics. Salient Features Sturdy construction for long term use Compact in design and space saving Safe and trouble free performance Microprocessor PID controller Over temperature and short circuit breaker Ventilation or chimney at the back Uniform heating inside chamber Temperature Range: Noida Machine Tools meet unique needs of every application, our muffle furnaces, Tube Furnace or box furnaces are available in temperature range from 800°C to 1400°C (800°C, 1100°C, 1200°C and 1400°C), in addition, we also design and manufacture high temperature muffle furnace up to 1800°C (1500°C, 1600°C, 1700°C, and 1800°C). Safety Features: These systems are microprocessor controlled programmable muffle furnaces that offer easy and safe operation even at high temperature. These systems are designed with your safety in mind. Multi-layered insulation keeps external surfaces (cabinet) cool to the touch. Door safety switch (optional accessory) stops power to heating elements when door is opened.

Rotary Retort Furnace

Get Price Quote

Electrically Heated Tilting type Rotary Retort Furnace can be used for Hardening and Tempering of various items such as Screws, Nuts, Chain Links, Springs, Bearing Races, Needles, Balls etc.

Roller Hearth Furnace

Get Price Quote

01 Piece (MOQ)

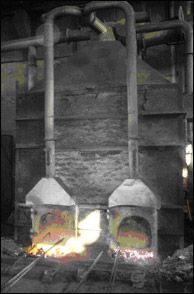

DOUBLE TEMPLE FURNACE

Get Price Quote

Lead to be manufactured from Mini Blast Furnace is usually obtained from scrapped batteries. They are cut open or broken to segregate lead scrap, plastic and other materials from it. Lead scrap in the form of lead powder and plates etc. is charged inthe furnace along with a proportionate charge of wooden coke. Thereafter the furnace is manually fired with the help of rags.FD Fan provides the necessary air required for combustion from the back of the furnace. Coke in the oven performs thefunctions of both, the fuel as well as a reducing agent for obtaining lead from its oxides charged in the form of lead plates & Powder.Temperature of the furnace is maintained at the desired level for approximately 30 minutes, after which molten lead along with slag flows out from the bottom of the oven into the outlet pit. Here slag is separated and molten lead is poured into IngotMoulds. To maintain this, continuous charge of raw material and coke is maintained in the furnace.This process leads to generation of flue gases which are toxic in nature and need appropriate and adequate Air PollutionControl System for their treatment.

heat treatment furnace

Get Price Quote

rotary furnaces

Get Price Quote

Lead to be manufactured from Rotary Furnace can be obtained directly from scrapped batteries or as slag from Mini Blast Furnaces In case of former batteries are cut open or broken to segregate lead scrap, plastic and other materials from them;lead scrap in the form of lead powder plates etc. is charged in the furnace along with a proportionate charge of additives. InThe case of latter, slag produced from Mini Blast Furnaces is charged into the Rotary Furnace, again with proportionate additives.

Pit Pot Furnace

Get Price Quote

Electric Arc Furnace

1,000,000 Per Piece

1 unit (MOQ)

Diffusion furnaces

Get Price Quote

Diffusion furnaces are designed for optimum temperature accuracy and stability. Enclosed in a unitized, rugged and thermally insulated cabinet structure, up to 4 heating elements are packaged for easy maintenance and extended service life. Furnace Cabinet: Unitized structural steel assembly Hinged, locking and removable element access doors Thermally insulated enclosure paneling High temperature Urethane coating Easy-to-adjust element alignment supports Cabinet overtemperature interlock sensor Leveling pads and optional seismic brackets Toxic Gas Scavenger: Stainless steel construction Vents gases and heat from process tube or chamber Indepently adjustable exhaust draw per tube-level Cantilever closure or manual door sealing per tube-level LPCVD flange and gas line fitting mounting scheme Differential pressure gauge to monitor exhaust draw Air-to-water Heat Exchanger: Used to vent heated air from furnace cabinet top HVAC control of furnace room Water-cooled, high efficiency radiator Air baffle paneling to direct air flow through cabinet Exhaust fan module for air exhaust draw Power Distribution: Located within base of furnace cabinet Encloses transformers, terminals and wire bussing Encloses temperature controls and contactors/breakers Easy accessibility to components Pull down panels for easy access to control modules EMO safety controls Reduncant overtemperature interlock per element zone Element Kits: Elements Low temperature range element 350 to 900oC Mid temperature range element 600 to 1200oC High temperature range element 600 to 1350oC +/- 0.5oC tolerance 600 to 1350oC range +/- 1.0oC tolerance 350 to 600oC range Vacuum formed high purity alumina insulation Stainless steel shroud Helical windings with captive spacing Control and overtemperature TC spikes per zone TC wire channel TC holding and alignment clips Energy Kits High purity alumina vestibule blocks NEXTEL soft collars Stainless steel capture rings, plates and collars Power Controls: High efficiency digital SSR/SCR firing circuitry Power control and circuit protection with EMO NEC-grade wiring Easy accessibility to components Main and control power disconnect contactors Individual element power contactors and resets Illuminated power indicators Redundant overtemperature interlocks 208, 380, 415, 480VAC main power, 50 or 60Hz

Muffle Furnace

Get Price Quote

Bell Furnace

Get Price Quote

Bell Furnace, thyristor operated control panel

Furnaces

Get Price Quote

Furnaces, Hot Runner Mold Heater, Infrared Heater Elements

Ladle Refining Furnace

Get Price Quote

Ladle Refining Furnace, Transfer Presses - Straight Sided Presses

Industrial Furnaces

Get Price Quote

industrial kilns, Industrial Ovens

Muffle Furnace

Get Price Quote

laminar flow cabinets, programmable furnace

Sintering Furnace

Get Price Quote

Sintering Furnace, Industrial furnaces

Industrial Furnaces

Get Price Quote

Hydraulic Trolley, Surface Winding Slitting Machines, coil binding machine

heat treatment furnace

Get Price Quote

heat treatment furnace, Gas Drying Systems, Industrial Gas Analysers

Vacuum Furnace

Get Price Quote

Vacuum Furnace, edm electrodes, Graphite Products, Continuous Casting Dies

Furnace

Get Price Quote

Furnace

Melting Furnaces

Get Price Quote

Melting Furnaces, Annealing Furnaces, heat processing equipment

Industrial Furnaces

Get Price Quote

furnaces parts, plastic auto parts die moulds, Plastic Moulds

Furnace

Get Price Quote

Furnace

Industrial Furnaces

Get Price Quote

electric kilns, Electric Ovens

Furnaces

Get Price Quote

Furnaces

Electric Induction Furnace

Get Price Quote

Electric Induction Furnace, Steel Making Process

induction remelting furnaces

Get Price Quote

induction remelting furnaces, 3d laser scanning microscope