Stencil cleaner Pneumatic Stencil Cleaning machine SMT Line cleaning for PCBA steel mesh cleaning

500,000 - 600,000 Per set

1 Set (MOQ)

Function: This pneumatic stencil cleaning machine is specially used for cleaning solder paste, red glue, silica gel and other residues on printed stencils Features: 1. completely use compressed air as energy, no electricity, there is no fire hazard 2. dedicated to cleaning SM T steel mesh, P C B MFP and printing press scraper and so on 3. equipment using precision filtration system 4. lean + dry process to ensure cleanliness 5. The liquid pressure can be displayed by the hydraulic gauge on the operation panel 6. independent exhaust device designed to make the liquid consumption lower 7. one-button operation, easy to operate easy to clean, dry work Specification: (L×W×H) Max Stencil size Max 750×750×40(mm), size can be customized Liquid tank 40L(Max) Optimal liquid tank 35L Clean method 360°rotation spray clean + compressed air blow dry Clean time 2-5 Min (General process) Dry time 2-5 Min (General process) Air pressure 0.45Mpa~0.7Mpa Tin slag filtration Three-stage filtering Level 1 filtering 10μm (Filtering impurity) Level 2 filtering 5μm (Filtering solder paste and small particles) Level 3 filtering 1μm (Filtering rosin and particles) Exhaust port size Φ120×H40(mm) Machine weight 200kg (L×W×H) Machine size 945×650×1645(mm)

Country of Origin : Taiwan

...more

solder pasteSMT Automatic Unloader PCBA Production Line Loader Dual-Rails Unloader

400,000 - 600,000 Per set

1 Set (MOQ)

Functions: Equipped at the end terminal of SMT line, designed for unloading the PCBs, sensors are provided to prevent platform movement until the PCB has been fully inserted into the magazine automatically, dual controlling system, independent control system, reduce labor, double increase the productivity efficiency. Features 1. The exterior structure is made of full sheet metal welding, surface treatment by spray coating for the sealing plate; 2. PLC control system +Touch-screen panel which is stable and reliable, easy to operate. 3. The push force can be adjusted according to PCB thickness to avoid damage of PCB caused by magazine deformation. 4. The lifting adopts precision ball screw, which has the characteristics of high speed, low noise, high precision and durability. 5. Trouble-locating and security detection system, visual sound-light alarm; 6. Equipped with standard SMEMA signal lines, which can be connected to other equipment for online automatic operation. Specifications Model Standard mode DimensionL×W×H L1506×W1447×H1503mm Applicable Magazine 355×320×563mm PCB SizeL×W 350×50~250mm Air Pressure 5KGf/cm² Power Supply AC220V 50/60HZ Transport Height 900±20mm PCB Thickness 0.6~4mm Transport direction L-R or R-L (optional) Rack Lifting Step 10,20,30,40mm Control Mode PLC+ Touch Screen

Country of Origin : Taiwan

Material : Stainless Steel

Certification : ISO 9001:2008 Certified

Application : Industrial

Automatic Grade : Automatic

...more

automatic smt pcb board screening buffer assembly line

185,000 - 280,000 Per set

1 Set (MOQ)

Function: This equipment is used before and after SPI, AOI, or in the production line for temporary storage. Features: 1 Robust steel structure design improves the stability of the equipment; 2 Smooth and parallel width stainless steel screw adjustment method; 3 PLC control work is stable and reliable + touch screen control interface; 4 Imported photoelectric sensor to prevent false induction, safer and more reliable; 5 Stable and accurate lifting mode (servo motor is selected) 6 Optional mode: rejection, detection or pass throgh (and buffer mode); 7Variable speed control; 8The length of the machine can be customized; 9Adopt a special conveying track design to prevent jamming; 10 Heavier bottom design, not easy to transposition; 11With four-core SMEMA signal cable, which can be communicate with other equipment to achieve inline operation; Specification: Model WIT-NG250 Overall dimension L*W*H 1000×680×900(mm) PCB size L×W 50×80~460×350(mm) Operating height 900±30(mm) Air pressure and air flow 4-6bar, up to 10 liters/minute Conveyor type flat belt Transmission speed 0.5-20m/min PCB thickness Min 0.6mm thick PCB storage capacity 10 pieces Storage height 20mm

Country of Origin : Taiwan

...more

SMT Lead-Free Wave Soldering Machine for DIP production

1,920,000 - 2,400,000 Per SET

1 Set (MOQ)

Features: Transportation: Input board directly. Stainless steel chain conveyor, durable and special design for aluminum alloy track. Applied floating track for different stages for preventing deformation. Pre-heating zones: Design for energy saving and removable modules (drawer design). Easy conversion between air flow and IR emitter heating system. Temperature uses the PID control to achieves accuracy-heating zone and soldering zone is less than℃. Flux spraying system. The motion of the spray nozzle is controlled by a stepper motor. Exhausting and filter system installed on the top-corrosion ceramic coating equipped with two low flow rate nozzles : cooling rate4 ℃ /s PC. Windows operation interface with Chinese. Saving and loading parameter setting

Country of Origin : Taiwan

Type : Smt Machine

Warranty : 1 Year

Brand Name : SZWIT

Material : Mild Steel

Operating Mode : Automatic

Shape : Rectangular

Corrosion Resistance : Yes

Certification : ISO 9001:2008 Certified

Machine Structure : Horizontal

Color : White

Condition : New

Driven Type : Electric

Width : 4420

Machine Weight : 100-1000kg, 1000-2000kg

Packaging Type : Wooden Box

Capacity : 480kg or above

Finishing : Powder Coated

Dimension (LxWxH) : 4420×1420×1750mm or above

...more

automatic smt pcb board flipper inverter

200,000 - 320,000 Per set

1 Set (MOQ)

Function: This machine is used to inverter flip PCBs (180degrees) for double side process. Features: PLC control system +Touch-screen panel which is stable and reliable, easy to operate.; Flipping power supply by stepping motor, speed fast; With preventing plate to avoid board stuck, optical sensor to make sure the flipping safety; Professional guide rail design with all aluminum material, Swift, smooth and precise operations; Full closed design make sure the highest operation protection level; Trouble-locating and security detection system, visual sound-light alarm; Standard SMEMA signal cable to communicate with other equipment to achieve inline operation. Specification Model WIT-PC460A DimensionL×W×H 603×970×1250(mm) PCB SizeL×W 50×50-535×460(mm) PCB Thickness 0.6-4(mm) Transport direction L-R or R-L (optional) Transport speed 0.5-5m/min Transport Height 900±30(mm) Power Supply AC220V±10V,50/60HZ Power 500W Control Mode PLC+ Touch Screen

Country of Origin : Taiwan

Type : Smt Machine

Color : White

...more

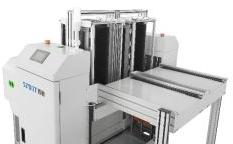

smt automatic dual-rails unloader pcb production line

400,000 - 640,000 Per SET

1 Set (MOQ)

Functions: Equipped at the end terminal of SMT line, designed for unloading the PCBs, sensors are provided to prevent platform movement until the PCB has been fully inserted into the magazine automatically, dual controlling system, independent control system, reduce labor, double increase the productivity efficiency. Features 1. The exterior structure is made of full sheet metal welding, surface treatment by spray coating for the sealing plate; 2. PLC control system +Touch-screen panel which is stable and reliable, easy to operate. 3. The push force can be adjusted according to PCB thickness to avoid damage of PCB caused by magazine deformation. 4. The lifting adopts precision ball screw, which has the characteristics of high speed, low noise, high precision and durability. 5. Trouble-locating and security detection system, visual sound-light alarm; 6. Equipped with standard SMEMA signal lines, which can be connected to other equipment for online automatic operation. Specifications Model Standard mode DimensionL×W×H L1506×W1447×H1503mm Applicable Magazine 355×320×563mm PCB SizeL×W 350×50~250mm Air Pressure 5KGf/cm² Power Supply AC220V 50/60HZ Transport Height 900±20mm PCB Thickness 0.6~4mm Transport direction L-R or R-L (optional) Rack Lifting Step 10,20,30,40mm Control Mode PLC+ Touch Screen

Country of Origin : Taiwan

Certification : CE

Application : Industrial

Automatic Grade : Automatic

...more

PCB Shuttle Conveyor Automatic SMT Production Line Board Transportation Conveyor

200,000 - 640,000 Per set

1 Set (MOQ)

Product Description Function:The surface mount PCB shuttle conveyor can be used for PCB board transport from one-track machine to dual-track placement machine for subsequent production. This one-track to dual-track transport can save labor cost and improve production efficiency.Features: The exterior structure are welded with metal plate and spray coated for the outer surface. PLC + touch screen display, more stable and easier to operate; Professional guide rail design with all aluminum material, Swift, smooth and precise operations It is equipped with intelligent touch screen control interface which is quite convenient. Shuttle Speed, distance, board deliver timing setting by software and sound-light alarm function. Stepping motor and sever motor to ensure the accuracy, stability and longer lifetime. 7.Shift mode:One-track in one-track out, one operating shuttle cycleTwo-track in one-track out, two parallel shift operating cycle 8.With Standard SMEMA to communicate with other machines to achieve inline operation. 9.Shuttle sizes can be customize upon request.Specifications: overall dimension customize PCB Size L350×W(50-250)mm operating height 900±30mm transmission direction L-R or R-L power voltage AC220V air pressure 0.5MPA positing mode Edge positing controlling mode PLC+ Touch Screen

Country of Origin : Taiwan

Type : Vertical Conveyors

Brand Name : SZWIT

Belt Material : Stainless Steel

Speed Adjustable : Yes

Certification : ISO 9001:2008

Color : White

Voltage : 220V

Condition : New

Corrosion Resistance : Yes

Machine Material : metal plate

Driven Type : Pneumatic

...more

mt automatic solder paste mixer

40,000 - 80,000 Per SET

1 Set (MOQ)

Function: This unit is fully automatic way of mixing solder paste. The internal motor rotates and turns, which is the mixing concept. The solder paste mixer has several advantages over manual mixing, including the ability to arbitrarily regulate the direction and duration of stirring as well as the unchanging mixing speed. Features: 1,Driven by high speed motor, fast speed and large torque; 2,Timer control, can set the mixing time; 3,Fully enclosed construction to ensure operator safety; 4,Adapt to the standard 500g solder paste bottles of various brands; stir 2 bottles in parallel; 5,The solder paste bottle does not need to be opened during the stirring process. stirred period about for 1-3 minutes. 6, Drive by electricity power only, no need air or other supply. 7,Mixing principle is on the basis of Motor rotation and revolution mode of agitation, no need to defrost the paste. Need to recovery the paste in short time, then the solder can be used after stirring well and deforming. 8,Process:Put in solder paste→Put the adapter on the other side→Close the lid and make sure there are no foreign objects inside the machine→Set the time→start →Automatic shutdown - take out7,Compatible With SMEMA interface which can be directly connected to other equipment. Specification: Model WIT-SPM500(Regular) Dimension(mm) 400×400×480(mm) Solder paste Can compatible DIAΦ60*H80 (suitable for general 500 g solder cream bottle) Remove air bubbles time 0-99H Revolution speed 600RPM/Min Rotation speed 350RPM/Min Power supply 1P AC220V 50/60Hz Control mode Timer + button switch Operational capability 2tanks*0-500G Mixing angle 45° Weight Approx.48Kg

Country of Origin : Taiwan

Type : MIXER

Application : Industrial

Color : White

Warranty : 12months

Brand Name : SZWIT

After-Sales Service Provided : Yes

...more

High Accuracy Semi-Auto Solder Paste Printer, Screen Printer, Stencil Printer SMT Machine

150,000 - 300,000 Per set

1 Set (MOQ)

Function: Semi-automatic solder paste printing machine is an equipment to use on SMT production, working principle is to using the stencil to print the solder paste on the specified pad, the good or bad solder paste printing, directly affect the final solder quality. Features: 1,Using precision guide rail and the Panasonic speed regulating motor to drive the scraper, ensure the printing stability and precision; 2,Printing scraper can be fixed up by rotate 45 degrees is convenient for printing stencil and squeegee cleaning and replacement; 3,Scrapers can be adjusted forward and backward to select suitable position; 4,Combined with a fixed groove printing plates and PIN, easy to installation and adjustment, adapt for single and double sides printing; 5,Calibration by using stencil movement, combined with printed (PCB), X, Y, Z. adjustment, convenient and efficient; 6,PLC + touch screen display, more stable and easy to operate; 7,Single direction, double directions or other kinds of printing methods can be set; 8,Automatic counting function, easy to statistics and arrange production; 9,Adjustable blade angle, steel blade, rubber scraper are suitable; 10,Touch screen with a screen saver function, the time can be adjusted to protect the touch-screen life; 11,Automatic alarm of cleaning the stencil , convenient for cleaning the stencil in time and ensure the printing quality; 12,Using AE unique programming design, easy to adjust printing scraper; 13,Display the printing speed and can be adjusted; 14,A special cylinder is used for lifting up and down to ensure stable operation. Specification: Model No WIT-SP680 WIT-SP1200 Dimension(L×W×H) L880×W680×H1660mm L1600×W680×H1750(mm) PCB Size(L×W) 320×450mm 320×1200mm Printing Platform size 450×320mm 1250×320mm Stencil Frame size 470×370mm~680×560mm 470×370mm~1250×550mm Printing speed 0-100mm/sec Power Supply 220V antiphase 50/60HZ Power Consumption 100W PCB board thickness 0.2-3.0mm Fixation of printing position PCB outer or pin positioning Micro adjust of table board Front/back±10mm;Right/Left±10mm Printing precise ±0.02mm Repeated and accuracy ability ±0.03mm Air Supply 4-7kg/cm2

Country of Origin : Taiwan

Type : Smt Stencil Printers

Certification : CE Certified, ISO9001

Weight : 0-100Kg

Color : White

Feature : Compact Design, Easy To Use, Fast Printing, Stable Performance

Voltage : 220V

Condition : New

Automatic Grade : Automatic

Power Source : Electric

Warranty : 1year

...more

Dual rails conveyor PCB handling machine

80,000 - 200,000 Per set

1 Set (MOQ)

Product Description Functions:The conveyor can be used as automatic connection line among equipment sets in SMT and AI production lines to save labor cost and connect front and following part of equipment setsFeatures: Independent electric box, modular control system, simple and beautiful wiring layout; Independently development by SZWIT with an integrated control board with stable performance; Board in and out control by the front and rear photoelectric sensors cooperate, The connection between the adjacent equipment in the SMT production line has the function of transmission and pause The transmission mode is double stepping motor, stepless variable speed, low voltage work is safer Double precision ball screws to adjust the width, Ensure the accuracy of width adjustment Hardened chrome-plated rods, widened guide rails and extended linear bearings, more stable in wear resistance One-touch operating to switch flow direction, double flow direction can be switched easily With SMEMA standard four-core signa cable which can be directly connected to other equipment. Specification: Model 0.5m (Single rail) 1m (Dual-rails) Supply voltage Single-phase AC220V/50-60HZ PCB width size(mm) 50~350mm Transmission height 900±30mm Overall Dimension L500×W1150×H905mm L1000×W1150×H905mm PCB Transport direction L~R (R~L One-key switch flow direction) Transport speed 1-12m/min(Adjustable)

Brand Name : SZWIT

Loading Type : Automatic

Country of Origin : Taiwan

...more

Automatic PCB Transportation NG OK Loader SMT Vacuum Loader unloader SMT Production line handling

400,000 - 600,000 Per set

1 Set (MOQ)

Function: The PCB NG/OK Unloader (Magazine Unloader) is the next station of AOI. The system is available to separate the No-good boards and OK boards from AOI and introduce the NG&OK boards into the corresponding magazines by special shuttle conveyor. Features: 1The control system adopts PLC control, and the interface adopts touch screen. 2Efficient management of NG/OK boards om upstream system. 3Stable casting-type lifting platform to ensure stability of the machine; 4Four-point pneumatic clamping function to ensure the accurate position of the magazine; 5Special gas circuit with photoelectric protection design function, effectively protection for damage of PCB board. 6Compatible SMEMA interface Specification Model WIT-NG&OK 250U Overall dimension L*W*H 1536×1447×1230(mm) Applicable material frame 355×320×563MM PCB Size L*W 350×50mm~250mm Air Pressure 5KGf/cm² Power AC220V 50/60HZ Transmission height 900±20mm PCB Thickness 0.6mm~4mm Transport direction L-R or R-L (optional) Material rack lifting distance 10,20,30,40(mm) Control Mode PLC+ Touch Screen

Country of Origin : Taiwan

Type : Automatic Capsule Filling Machine

Certification : Iso 9001:2008

Weight : 100-500kg

Color : White

Voltage : 220V

Condition : New

Automatic Grade : Automatic

Power : 3-5kw

Warrenty : 1 Year

Brand Name : SZWIT

Application : SMT Handling system

After-Sales Service Provided : yes

...more

Screen Printer

Stencil Printer

Smt Machine

Be first to Rate

Rate ThisOpening Hours