Rock Rebar FIBRE

Rock rebar is a unique composite material with a wide range of application in construction industry. It can sustain corrosion, aggressive chemical compounds, extremely light and durable. It is a bar with continuous spiral ribbing formed by means of winding by Rock fiber strip oiled in highly durable polymeric compound. Research results have shown that the service life of constructions, where Rock rebar is used, considerably exceeds the life of similar constructions where other materials are used. ADVANTAGES OF USING ROCK REBAR 4 times lighter then steel bar and in full-strength replacement it is 9 times lighter! As a result: Reduction of construction weight; Effectiveness during installation and maintenance works without special load lifting mechanisms and machinery; Transport cost effectiveness for construction delivery to the assembling place. 2) 3 times higher durability comparing to steel rebar! 3) Absolute corrosion resistance (unique chemical resistance to alkali, potash environment, hydrochloric acid, sea water and other aggressive environments). Thermally nonconductive. Dielectric The same thermal expansion coefficient as concrete’s. As a result: Increased reliability and durability of structures and Repair cost effectiveness.

...more

Rock Geomesh FIBRE

Rock fiber Geo Mesh is useful for reinforcing asphalt-concrete (covering in construction, reconstruction and repair of airports, runways, and highways and any pavements, pedestrian ways, road inclines and banks. The reinforcement of disc cutters with RF Geo Mesh increases their reliability, safety and the cutting process output. The strength of the net is as good as metal reinforcement, however, it is 2.6 times lighter, thus simplifying transportation and handling in construction. Rock fiber Geo Mesh is more durable than metallic and glass fiber reinforcement.

...more

Needled Felt

These felts provides very low thermal conductivity and can withstand continuous working temperatures in excess of -260°C/ 900°C, making it flexible material and ensures high temperature performance. They have excellent drape ability and conforms to irregular surfaces to meet a variety of design needs, its chemical properties makes it highly durable and safe. It is widely used in sound insulation, Heat keep preservation; Fireproof, Filtration and engine exhaust systems. Non combustible properties enable it to resist flames for long periods which make it effective as extra fine-resistance insulation for electric cables and underground ducts.

...more

Hollow Grouting

These products are easy to cut, has high strength, high torque, self-drilling and at the same time grouting. It is flame retardant, anti-static product, so safety in the process, does not produce sparks when cutting. Also safe to use in tunnel construction, especially suitable for gas region. Tensile strength of rod body is very strong and hard, the level of intensity is better than the equivalent diameter of reinforcing steel bar. The product is light in weight, easy to operate; only a quarter of steel weight on same specifications and easier to handle during construction, so as to reduce worker’s labor intensity, the product is the latest substitute of steel. Alternatively, it can reduce the energy consumption and environmental pollution when using steel products, also In line with the policy of energy saving in construction and emission reduction requirement.

...more

Heat Retaining Boards

This can be used for the exterior wall or the core of the wall, providing excellent heat reservation. It has high strength performance and sound absorption made it a new fireproof material for construction. HEAT RETAINING BOARD WITHOUT MINERAL WOOL These boards have high tensile strength, higher than 1 Mpa, high compressive strength: 465 Kpa, can be coated with ceramic tile. They also have high bond stress (can be drilled for anchor) make the construction simple and handy, highly efficient. It can resist high wind pressure; have good heat reservation for super high-rise building. It is preferably used for buildings higher than 24m. It resists shrink deformation and deformation in difference temperature. Further, it is a radiation resist, waterproof, durable product.

...more

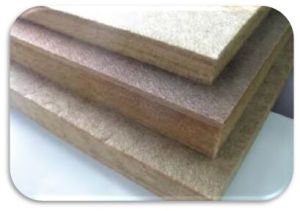

Heat Retaining Board with Mineral Wool

This can be used for the exterior wall or the core of the wall, providing excellent heat reservation. It has high strength performance and sound absorption made it a new fireproof material for construction. All these boards have 3mm thick rock fiber layer on both the sides, sandwiching the mineral wool in between.

...more

FRP Bolt

The FRP Bolt series provides unique advantages like easy cutting; rod plays a role of protection in coal mining head. It is a flame retardant, antistatic product, so safety in the process, does not produce sparks when cutting. Also safe to use in tunnel construction, especially suitable for gas region. Tensile strength of rod body is very strong and hard, the level of intensity is better than the equivalent diameter of reinforcing steel bar. The product is light in weight, easy to operate, only a quarter of steel weight on same specifications and more easy to handle during construction, so as to reduce worker’s labour intensity, the product is mainly to substitute the original use of steel, wood and bamboo sticks.

...more

Basalt Chopped Fiber

The Basalt or Rock fiber is manufactured by crushing a rock of a special chemical structure followed by its melting in furnaces at high temperatures, i.e. more than 1500 °С. This complex fiber consists of 200 elementary filaments that are binded with special oiling liquid (sizing) and is out stretched through a special device, named feeder, at the bottom of the furnace. Types of sizing process are selected depending on further contact environment of Rock fiber fibers in order to ensure maximum adhesion. Ultimately, after the polymerization phase, it results in subsequent formation of rock chopped fiber or assembled continuous roving (which is used for Rock rebar manufacturing). Mixing Technique For stationary concrete mixing machines: Rock fiber reinforced concrete mixture is recommended to be prepared in compulsory batching plants (BSU); For a uniform distribution of Rock fiber throughout the volume of concrete Rock fiber is recommended to be introduced (automatically or manually) with sand and gravel on the tape BSU by gradual dose It is recommended to increase the mixing time of mixture with fiber for not more than 20% of the mixing time of concrete without fibers; It is strictly forbidden to add Rock fiber in a ready-made concrete mix in order to avoid lump formation and "urchins" For on-site concrete mixers (agitators): Dry sand, cement, gravel is added into the rotary mixer and Rock fiber must be added gradually. Water is added only after a uniform distribution of fibers throughout the volume of mixture. For a uniform distribution of Rock fiber throughout the volume of concrete we recommend to add Rock fiber manually while adding sand into the mixer; It is recommended to set the optimum mixing time of Rock fiber and sand for its uniform distribution in the concrete mix. Recommended dosage is from 1 to 5 kg of Rock fiber for 1 m3 of concrete mixture. ADVANTAGES OF ROCK FIBER IN CONCRETE: Easy Concrete pouring (after a few hours you can remove the formwork) Provide a proportional three-dimensional reinforcement; Lightweight, high mechanical strength, high corrosion and chemical resistance to alkalis, acids and other aggressive environments; Frost resistant, waterproof; Sound absorption; Resistance to salt sea water; Resistance to ultraviolet radiation; Dielectric; Ecological.

...more

Hydro Electric Project Service

Be first to Rate

Rate This