Triple Stage Battery Cutting Machine

Get Price Quote

The Triple Stage Battery Cutting Machine, which we offer, is manufactured in confirmation to the established industrial standards. We are amongst the reliable Sources to source these Triple Stage Battery Cutting Machines. Also, this Triple Stage Battery Cutting Machine is manufactured using the leading-edge technology. Details This machine has an automatic conveyor Battery is placed on the conveyor Width of Battery, need not to be set It can accommodate Battery up to Max. Width of 305mm (Most of Batteries are less than this) This machine has three Blades for Cutting Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel (This wheel is visible in picture of machine) Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting. First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo, etc. will be cut and that portion ejects out from first window Second Cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed. This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility. Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump. Water is collected in the bottom tank This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining. Situated in Noida (Uttar Pradesh), we have built a wealth of reputation for manufacturing, supplying and exporting the superior-grade Triple Stage Battery Cutting Machines across the globe. Attainable at market-leading prices, the Battery Slicer (Triple Stage) is distinguished for its hassle free functions for a long span without much upkeep. For utmost gratification of the clients, we dole out quality-tested Battery Cutting Machines in tailored specifications. Specifications : Out Put Capacity : Two to Two and Half Ton/ Hour. Power Requirement : 16 Kw, 440 Volt, 3 Phases, 50 Hz. Man Power Requirement : Two no. unskilled Labor Operational Expenses for battery Breaking per ton : $ 2.10/ Ton approx Description : This Machine has One Conveyor, Three Cutting Stations with one Bend Saw Blade each. Conveyor is used to feed the batteries into machine and Cuts off batteries at three respective set heights, as set by the operator. Blades are water cooled. After Cutting operation, Cut batteries are transported out of the machine by conveyor. Cut (Sliced Off) Top of battery is ejected out automatically from first window and Connection Strap and part of Container from Second Window and third blade as stand by so during slicing off if one of the blade become blunt then another station is utilized and production is not interrupted. Other option is if Bigger battery with more height is fed then it can be sliced off into four Pieces. Maximum Height of batteries can be fed to the machine is 600 mm and width being 305 mm. Fume are collected and restricted by the Enclosed Body of Machine. No human exposure is involved in Cutting operation. Exposure of acid fumes and lead meet best environmental practices in the world No. Adjustment of Width is required. Operation of Machine : Batteries are placed on the moving conveyor. Top of Batteries is sliced off by high Speed Bend Saw. There is one Bend Saw with height adjustment to set Cutting (Slicing) Height. Height is set manually. Sliced off Lid from first window is ejected out. Then battery moves to second cutting Blade, here Connection Strap and Part of Container is Sliced off which is also ejected out from Second Window. If more height battery is sliced off then part of Plates and Container is also sliced off and Remaining Part of battery is transported by the conveyor to other end of the machine, where it is toppled into Acid Draining Attachment. Output of Machine : Battery Top Connection Strap with Container Part Part of Plates and Container Remaining part of Battery. Acid Drained out in to Acid tank.

Semi Automatic Filling Machine

Get Price Quote

We are offering semi automatic filling machine. Piston filling machine for filling yogurt, ketchup and other viscous products. can be fixed with complete automatic filling machine which includes automatic cup placement, cup filling, lid placement and cup ejection. inquire to know more about the product.

Best Deals from Industrial Machine

Filling Machinery

Get Price Quote

All-Fill liquid filling machines combine precision, speed and versatility in liquid filling technology designed for liquids, pastes, creams and other viscous products. Our line of liquid filling machines come in a variety of sizes: from tabletop machines for small containers, to heavy-duty equipment designed for high-speed, high-cycle rate dispensing. Liquid filling machines feature various nozzle configurations to match specific production requirements.

Head Automatic Cup Filling Machine

Get Price Quote

Drum Filling Machine

225,000 Per Piece

semi automatic machines

Get Price Quote

We are offering semi automatic machines. Our respected firm is widely applauded in the industry for providing a comprehensive collection of semi automatic machines

Digital 5 In 1 Heat Transfer Machine

Get Price Quote

We understand that the use of finest grade raw material brings forth high quality product line. In addition to this, we make sure that the material is sourced from the reliable places only. The payment methods we opt are highly confidential and we have maintained a well-organized database listing all the transaction details and clients' personal details to avoid any confusion.

Liquid Filling Machine

Get Price Quote

1 Piece (MOQ)

Led bulb making machine

Get Price Quote

It is called bulb making machine and you cane make more than 100 bulbs in 1 hrs

Aluminum Foil Rewinder Machine

Get Price Quote

Newcore Global Pvt. Ltd is an professional manufacturer, export and supplier of Automatic Aluminum Foil Rewinder Machine. The offered rewinder machine is designed by using quality proven components and innovative technology under the guidance of adept professionals. Our provided rewinding machine is available in different designs and specifications as per the requirements of our customers. ATW-AF600 Automatic aluminum foil rewinder For Aluminium foil : 1.Thickness of raw material: 0.009mm0.02mm 2.Width of raw material: 100-500mm 3.Maximum unwinding diameter: Φ 600mm 4.Inner diameter of parent roll core: 76mm/152mm (option) 5.Inner diameter of finished product roll core:Φ 25 Φ30 Φ35mm (option) 6.Finished roll length:3m–300m 7.Production speed:0-150m/min 8.Unloading magnetic powder brake: 25N.M 9.Winding magnetic powder clutch:12N.M 10.Overall dimension: 4000*1350*1710mm 11.Total power:4KW 12.Compressed air pressure: 0.5 Mpa; (prepared by the customer) 13.Total Weight: About 1500KG

Battery Plate Parting and Brushing Machine

Get Price Quote

CENTER FILLING INJECTOR CUM CAKE DEPOSITOR(SERVO MODEL)

Get Price Quote

Technical Features - Injecting in Cakes/Buns (post baking) - Depositing cup cake batter/similar viscosity batter of any sort - Top depositing of cream/jam/glaze on any kind of product - The weight of the injection can be in between 3 gm to 25 gm - The machine injects accurately repeatedly - The machine is also fitted with a PLC and touchscreen display from where the operator can feed the dosage & store them for future quick changeovers - It has 7 individual pistons to inject in individual cavities at the same time - The machine can also be customized as per the requirement

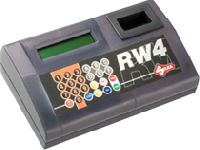

duplicate key making machine

Get Price Quote

The Joint Venture between Spark Minda, Ashok Minda Group, India and Silca Inc., Italy prompted Minda Silca to venture into After market business. The 1st objective is to tap the huge market in India. This will be followed by venturing into SAARC countries. Minda Silca has started to spread its wings in the country and now has a national footprint with 13 distributors and over 5000 clients spread in different geographic locations in India. Minda Silca is committed to upgrade and uplift the unorganized key cutting business in the country. As a result it has opened its first hi-tech Key duplication center at Noida. This center is equipped with most sophisticated mechanical and electronic machines to duplicate all possible type of keys that exist within the market. Minda Silca in aligning the key cutters with this center. The objective is not only to provide all round training but also allowing them to use these hi-tech machines for duplicating keys for their customers as well. There are plans to open more such centers in the country.

glass filling machine

Get Price Quote

We are rumored substance offering exceedingly requested Water Glass Paching Machine. The offered model is requested broadly for its adaptable execution in an assortment of fixing materials running from PEPP to PET and PE. Moreover, this machine of Water glass filling machine is appropriate for filling juice mugs and its wide temperature range can be improved to fill hot drinks and other sustenance items in these containers. .

automatic auger filling machine

Get Price Quote

Cup Filling Machine

Get Price Quote

Cup Filling Machine, Heat Exchangers, Pressure Cooker, Vegetable Washer

Velvet

Get Price Quote

Velvet

Industrial Equipment

Get Price Quote

Industrial Equipment, Weighing System, control panel accessories

Semi Automatic Filling Machine

Get Price Quote

Semi Automatic Filling Machine, Automatic Pouch Packing Machines

packaging industry machine

Get Price Quote

packaging industry machine, Die Cutting Machine, Dry Vacuum Pump

Battery Manufacturing Plant

Get Price Quote

Battery Manufacturing Plant, Resin Manufacturing Plant

Shrink Wrapping Machine

Get Price Quote

Shrink Wrapping Machine, semi auto strapping machine

brake lining machines

Get Price Quote

brake lining machines

lead smelting furnace feeding systems

Get Price Quote

lead smelting furnace feeding systems, gas cleaning plants

industrial cloth cutting machines

Get Price Quote

industrial cloth cutting machines, horizontal cloth cutting machines

Automatic LPG Filling Machine

Get Price Quote

Automatic LPG Filling Machine, LPG Vaporizer Wet Type

Nitrogen Filling Machines

Get Price Quote

Nitrogen Filling Machines, tubeless tyre repair

rotary label printing machine

Get Price Quote

rotary label printing machine, Flexo Rotary Label Press