water cooled spindles

Water Cooled Spindles We offer water-cooled spindles that are suitable for a wide range of machining operations on wood, plastic, aluminum, brass, steel, and more. In addition, these spindles are designed to provide high precision and durability. Furthermore, they ensure consistent performance even under demanding conditions. As a result, you can achieve better machining accuracy and efficiency. Ultimately, investing in water-cooled spindles can enhance the overall productivity of your CNC machine.

...more

universal angle head

Universal Angle Head or Miling Head is ideally suitable for VMC/HMC for improving productivity, by avoiding number of setups. BT40-ER25 Universal Angle Head (AHG Type) Run-out:0.002 mm Squareness:10 Arc Second Material:Alloy Steel & Ductile Cast Iron(FCD65) R.P.M.: Max. 4000 RPM Torque: Max. 20 Nm Gear Ratio:1:1 Spindle Type:BT, NT, SK(ISO), CAT Standard Accessory:Open End Wrench, ER Wrench, ER Nut Output Rotation: Reverse to Input Rotation.

...more

Turning spindle

We offer a High-Speed Turning Spindle used for cutting, drilling, or shaping material in turning operations.

...more

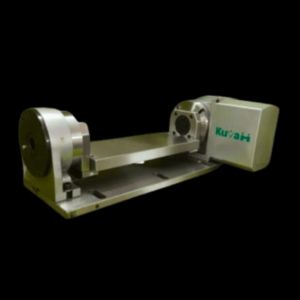

Rotary Table - 4th Axis

4th Axis Rotary Table is an advanced CNC machine accessory that introduces rotational movement to machining operations. While traditional CNC machines operate along three linear axes (X, Y, and Z), the 4th axis adds a rotational A-axis, enabling the workpiece to spin around one of the linear axes. This table is typically mounted on a vertical or horizontal machining center and works in synchronization with the CNC machine, enabling precise, multi-dimensional machining. n modern manufacturing, precision and efficiency are critical. A rotary table offers the ability to: Achieve Complex Machining : Perform intricate cuts, curves, and angles with ease. Save Time: Eliminate manual repositioning and achieve faster production cycles. Increase Accuracy: Execute operations like gear cutting, indexing, and engraving with micrometer-level precision. Whether working in aerospace, automotive, or precision engineering, a rotary table is indispensable for multi-faceted machining.

...more

ROTARY PRODUCTION SYSTEM

A Rotary Production System is an advanced tool used in machining processes to enhance productivity, precision, and efficiency. It integrates rotary tables with intelligent mechanisms like pneumatic or hydraulic clamping, robust gear systems, and high-performance bearings. These systems are crucial for industries requiring high-speed, multi-directional machining with consistent accuracy. In modern manufacturing, where time and precision are critical, the Rotary Production System addresses key challenges: Enhanced Efficiency: It reduces the need for multiple setups by allowing multi-axis machining in one go. Increased Accuracy: Ensures precise machining operations, even for complex geometries. Time Saving: Accelerates production timelines with automated mechanisms. Cost-Effectiveness: Minimizes material wastage and labor costs by reducing errors and rework.

...more

rotary indexing tables

400,000 - 500,000 Per piece

Located in Chhattisgarh, we are a leading manufacturer of high-quality rotary indexing tables, designed to optimize automation and precision in manufacturing processes. Our rotary indexing tables are engineered for durability, accuracy, and efficiency, catering to a wide range of industrial applications. We offer a variety of models, including cam-driven, servo-driven, and custom rotary indexing tables, each tailored to meet specific operational requirements. Committed to innovation and excellence, we ensure our products enhance productivity and performance. With advanced technology and a skilled team, we are the preferred choice for rotary indexing solutions in India and beyond.

...more

Manual Tool Change Spindle

Hiteco Manual Tool Change Spindle is ideal for CNC Router Machines, plastic, and aluminum, brass. They are available in Air Cooling and Water Cooling.

Voltage : 220/380 V

...more

Manual Boring Head

Manual Boring Head Maximum Torque: 1000 Nm Maximum RPM: 2000 rpm Rotating Direction of Spindle: Clockwise Tool Type: MAS 403 BT-50 Pull Stud: MAS 403 P50T-1 Tool Specification: BT – #50 Model Type: GME Ratio: 1:1 Minimum Horsepower: 38kW Maximum Tool Diameter: Ø150 mm

...more

Manual 90 Degree Extension Milling Head

Manual 90 Milling Head

Manual 90° Milling Head Maximum Torque: 1000 Nm Maximum RPM: 2000 rpm Rotating Direction of Spindle: Clockwise Tool Type: MAS 403 BT-50 Pull Stud: MAS 403 P50T-1 Tool Specification: BT – #50 Model Type: GMA1 Ratio: 1:1 Minimum Horsepower: 38kW Maximum Tool Diameter: Ø150 mm

...more

Manual 500 Extension Head

Manual 500 Extension Head Maximum Torque: 1000 Nm Maximum RPM: 2000 rpm Rotating Direction of Spindle: Clockwise Tool Type: MAS 403 BT-50 Pull Stud: MAS 403 P50T-1 Tool Specification: BT – #50 Model Type: GMC1 Ratio: 1:1 Minimum Horsepower: 38kW Maximum Tool Diameter: Ø150 mm

...more

Hydraulic Rotary Indexing Table

A Hydraulic Rotary Indexing Table is a precision device used in machining applications to position a workpiece at specific angles during manufacturing processes. It utilizes hydraulic power to achieve controlled rotational movements, making it an essential tool for operations requiring repeatability and precision. These tables are often used in combination with machine tools like CNC machines, drilling machines, and assembly lines. Enhanced Efficiency: Automates the positioning process, reducing manual intervention and cycle times. Precision in Positioning: Offers high indexing accuracy for intricate machining or assembly tasks. Durability in Heavy Operations: Built to handle high loads and frequent operations, making it ideal for industrial use. Versatile Applications: Suitable for drilling, milling, inspection, and assembly lines.

...more

Heavy Duty Angle Head

Heavy Duty Angular head are ideally suitable for VMC/HMC for improving productivity, by avoiding a number of setups. Heavy Duty Angle Head (AHG Type) Run-out:0.002 mm Material:Alloy Steel & Ductile Cast Iron R.P.M.:Max. 4000 RPM Torque: Max. 100 Nm Drilling:24mm Tapping:M18 Gear Ratio:1:1 Spindle Type:BT, SK(ISO), CAT Standard Accessory:Open End Wrench, L Type Wrench Output Rotation: Reverse to Input Rotation.

...more

mtc spindle

225000 piece (MOQ)

MTC Spindle is a premier spindle manufacturer based in Uttar Pradesh, renowned for its high-quality spindle solutions tailored for various industrial applications. With years of expertise in spindle manufacturing, MTC Spindle offers a diverse range of products, including precision spindles, CNC spindles, and custom spindle solutions. Our state-of-the-art manufacturing facility, equipped with advanced technology and a skilled workforce, ensures the highest standards of quality and performance. MTC Spindle is committed to innovation, reliability, and customer satisfaction, making us the preferred choice for industries across India and globally.

...more

Direct Driven Spindle

We offer a wide range of Direct Driven Spindle for Drilling and Milling Machines. They are more compact and economical, compared to Built-in Motor Spindle

Power : (KW)

...more

Tilting Rotary Table

Enhanced Machining Capabilities: A Tilting Rotary Table allows machining on multiple faces of a component in one setup, reducing time and increasing productivity. Complex Geometry: It simplifies the process of machining angular surfaces, contours, and spherical designs. Precision and Repeatability: Ensures exact positioning and alignment for high-accuracy machining. Reduced Setup Time: Eliminates the need to reposition the workpiece, minimizing errors and downtime. Versatile Applications: Suitable for a variety of operations like drilling, tapping, engraving, and contour machining. A Tilting Rotary Table is an advanced accessory for CNC machines that combines the functionality of rotation (like a 4th Axis Rotary Table) with the ability to tilt at various angles. This versatile tool is essential for machining complex components requiring multi-angle precision and intricate detailing. It is widely used in industries such as aerospace, automotive, medical devices, and precision engineering, where the highest levels of accuracy and efficiency are critical.

...more

Cnc Rotary Table

225,000 Per piece

CNC Rotary Tables Indexing accuracy +/- 15 arc Sec Repeatability 4 arc sec With duel lead worm & worm wheel With axial radial roller bearing With pneumatic/hydraulic clamping Motor mounting on right side Motor mounting kit with sheet guard

Application : Industrial Use

...more

Built in Motor Spindle

We are offering Built-in Motor Spindles for Drilling and Milling. They can be used for high speeds compared to Belt Driven and Direct Driven Spindle.

Power : Kw

Voltage : V

...more

Belt Driven Spindle

We offer a wide range of Belt Driven Spindles for Drilling, Boring, and Milling Machine, Available in Different sizes BT30, BT40, BT50 . What is Belt Driven Spindles Belt-driven spindles are mechanical components commonly used in various industrial machinery for transmitting power from a motor to the spindle shaft via a belt and pulley system. In fact, these spindles are an essential part of machine tools like lathes, milling machines, drilling machines, and grinding machines. Therefore, they are highly valued in many industries. Features Of Belt Driven Spindles 1. Power Transmission via Belt To begin with, the spindle uses a belt-driven mechanism to transfer rotational energy from the motor. For example, different types of belts, such as V-belts or flat belts, are employed based on the application. Additionally, the flexibility of belt options allows for customization according to specific requirements. Thus, a belt-driven spindle is versatile. 2. Adjustable Speed Moreover, with a belt-driven spindle, the speed can be varied by changing pulley sizes or adjusting the belt’s tension, which means it is highly adaptable for different tasks. Consequently, operators can achieve desired operational speeds with ease. For instance, in precision machining, this variability is crucial. Similarly, woodworking machines benefit from this adaptability. In this way, belt-driven spindles offer significant advantages.

Weight : (Kg)

...more

Automatics Tool Change Spindle

We offer an (ATC Spindle) Automatic Tool Changer Spindle suitable for a wide range of machining operations on wood, plastic, aluminum, brass, steel, etc.

Weight : 21 KG

Voltage : 380V

...more

Automatic Extension Milling Head

Automatic Extension Milling Head Maximum Torque: 1000 Nm Maximum RPM: 3500 rpm Lubrication Method: Grease Cutting Cooling: Vertical External Cooling Tool Specification: BT – #50 Ratio: 1:1 Clamping/Unclamping Method: Automatic Clamping Force: 1200 – 1500 kgf Maximum Tool Diameter: Ø200 mm

...more

Automatic Boring Head

Automatic Boring Head Maximum Torque: 500 Nm Maximum RPM: 2000 rpm Lubrication Method: Grease Cutting Cooling: External Cooling Tool Specification: BT – #50 Ratio: 1:1 Clamping/Unclamping Method: Automatic Clamping Force: 1200 – 1500 kgf Maximum Tool Diameter: Ø150 mm Axis Split Angle (Automatic): 5°一a split

...more

Automatic 90 Small Milling Head

Automatic 90° Small Milling Head Maximum Torque: 1000 Nm Maximum RPM: 3500 rpm C-Axis Spit Angle(Automatic): 5° - a split Lubrication Method: Grease Cutting Cooling: External Cooling Tool Specification: BT – #50 Ratio: 1:1 Clamping Force: 1200 – 1500 kgf Maximum Tool Diameter: Ø200 mm

...more

Automatic 90 CTS Milling Head

Automatic 90° CTS Milling Head Maximum Torque: 1000 Nm Maximum RPM: 3500 rpm Lubrication Method: Grease Cutting Cooling: External Cooling Tool Specification: BT – #50 Ratio: 1:1 Clamping/Unclamping Method: Automatic Clamping Force: 1200 – 1500 kgf Maximum Tool Diameter: Ø200 mm C-Axis Split Angle (Automatic): 5°一a split

...moreBe first to Rate

Rate ThisOpening Hours