Membrane Bio Reactor

Get Price Quote

1 Piece (MOQ)

MBR combines biological treatment with membrane filtration, effectively separating treated water from sludge. This technology produces high-quality effluent and minimizes the need for additional clarification processes. Advantages: High-quality effluent, compact design, and reduced footprint.

Membrane Bio Reactors

Get Price Quote

Membrane Bio Rector (MBR) is the combination of membrane process like microfiltration or ultra filtration with suspended growth bioreactor. This very compact arrangement produce a MF/UF quality effluent suitable for reuse applications or as a high quality feed water source for Reverse Osmosis treatment. In MBR system the wastewater is brought in contact with the biomass and then under pressure, filtration through the membrane. The entire biomass is returned to the bioreactor. Excess sludge is pumped out order to maintain a constant sludge age and the membrane is regularly cleaned by backwashing, chemical washing or both. The entire biomass is confined within the system, providing both perfect control of the residence time for the microorganism in the reactor (sludge age) and the disinfection of the effluent. FEATURES Modular Quick Startup Compact design Small footprint Low operating cost No odour problem No chemical consuption High loading rate capability COD, Solids and Nutrient removal in a single unit No sludge bulking problem Low sludge production APPLICATION Wastewater from numerous industrial sources such as 1. Paper Mills 2. Beverage 3. Slaughterhouse 4. Food Processors 5. Chemical Plants, etc.

Best Deals from Membrane Bioreactor

Membrane Bio-Reactor

Get Price Quote

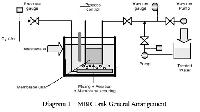

MBR (Membrane Bio-Reactor) can be broadly defined as systems integrating biological degradation of wastewater with membrane filtration. Set up of MBR plant is mainly utilizing a bioreactor and membrane filtration as one unit process for wastewater treatment thereby replacing, and in some cases supplementing, the solids separation function of secondary clarification and effluent filtration, resulting the possibility to eliminate the secondary clarification and operate at higher MLSS concentration. In summary, the MBR system is the combination of traditional Activated Sludge Treatment with the membrane technology. The design criteria of the system shall be base according to the traditional way of Activated Sludge Treatment principle. However, on top of that, the MBR modules are immersed and located in the air blow tank/ aeration basin (biological reactor tank), the clear water is pumped(sucked) out from the MBR modules. This shall possibly eliminate the needs of secondary clarifier. Refer Diagram 1. Features of the MBR: 1 Better control of biological activity 2 Effluent that is free of bacteria and pathogens 3 Smaller foot print 4 Biodegradation efficiency enhanced 20%~40% 5 Short Hydraulic Residence Time (HRT) & Long Sludge Residence Time (SRT) 6 Activated sludge increase by 2~3 times 7 Higher organic loading rates 8 Adopt high strength polypropylene material membrane, easy cleaning, long lifespan to 5-7 years. 9 Convenient management with automatic control system. How does it work: 1 Nos of pcs. of membrane are connected parallel through the header to form a frame. Connected frame network will form a Membrane Unit. 2 It is then connected the suction side of a permeate pump, the membranes are subjected to a slight negative pressure of 10 to 30 kPa (1.5 to 4.5 psi). 3 In an “outside-in” process operation, water is drawn from the mixed liquor through the membrane module and into the hollow fiber, further enhanced by suction effect of pump. From there, the treated water is drawn through the header and out through the discharge system. 4 On a continuous basis, air is pumped into the bottom header, where it emerges as a fine bubble stream. This air stream performs the triple role of process aeration, mixing of the biomass and membrane cleaning. Refer Diagram 1. 5 Also, with the continuous movement of air bubbles around and through the fibers, a lower concentration of biomass is maintained around the membranes and this, in turn, minimizes the potential for membrane fouling. 6 The membrane module are modular design and can be dismantled individually for manual cleaning as part of supplementary periodic maintenance.

Membrane Bio-Reactor

Get Price Quote

We are offering membrane bio-reactor. The mbr system is the combination of traditional activated sludge treatment with the membrane technology. The design criteria of the system shall be base according to the traditional way of activated sludge treatment principle

Membrane Bioreactor

Get Price Quote

Membrane Bioreactor, Hydro Extractor, Oil Water Separator, trickling filter

Membrane Bio Reactor

Get Price Quote

Set up of mbr plant is mainly utilizing a bioreactor and membrane filtration as one unit process for wastewater treatment thereby replacing, and in some cases supplementing, the solids separation function of secondary clarification and effluent filtration, resulting the possibility to eliminate the secondary clarification and operate at higher mlss concentration.

Membrane Bio-Reactor

Get Price Quote

Membrane Bio-Reactor can be broadly defined as systems integrating biological degradation of wastewater with membrane filtration.