SMALL DIAMETER EXPANDING SHAFT

Advantages Small Diameter Expanding Shafts are widely used for Sticker, Fax Roll & Label Printing Machines. Small Diameter Expanding Shaft has durable construction to hold the cores for the positive gripping. Small Diameter Expanding Shafts are flange mounting styles and it used for light to medium duty works.

Length : Upto 1 meters

...more

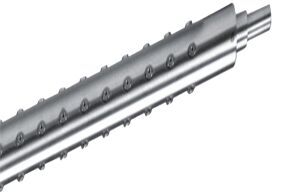

SLITTER KNIFE SHAFT

Slitter Knife Shaft is manufactured from high quality alloy steel. This shaft body is hard chrome plated and precision ground to match the inside diameter of your current anvils. Slitter Knife Shafts are available in custom diameter, length. This shaft is dynamically balanced and precision ground & chromed to the most precise tolerances. Outer body holds the anvils or knives.

Length : Upto 3 meter

...more

Slitter Knife

Safety Chucks

Safety Chuck is a safe, fast loading, rugged shaft support and drive that can be used on all converting equipment. The heavy duty construction allows for many years of safe and problem free use. Both the foot and flange mount chuck designs will suit all drive systems. The chuck insures a safe operation once a shaft is locked into place. The chuck will only open when the drive square is in the upright position. The square chuck sockets are available in both inch and metric sizes. We offer all types of Safety Chucks like – Tilt Type, Sliding Type, Flange Mounted & Foot Mounted, etc.

Warranty : 12 months any manufacturing defects

Warranty : 12 months for any manufacturing defects

...more

quick locks

Quick locks used in rewinding shafts of slitting machine. It is used to eliminate stretching of subs trait. Advantages Save job setting time. Can accommodate different length of core. Tension can be varied while running of machine. Can grip PVC core without slip. Unloading of finished roll is very easy. Eliminate paper core dust. Allocation of core is very easy.

Application : Multiple slit on One time such as PET, CPP, OPP, PE, PS, PVC, PAPER, FILM FOIL etc

...more

Pneumatical Adaptors

Pneumatic Adaptors are used for all types of winding and unwinding industry and it is easily mounted on the Pneumatics / Mechanical / Multi Tube Shaft. We produce with the highest quality adaptor and deliver in the shortest period of your demands and orders. This is our basic customer policy. These Adaptors are in the diameters of 3″, 4″, 6″ and 8″ and are produced at desired lengths.

Warranty : 12 months for any manufacturing defects

...more

MULTI TUBE CANTILEVER SHAFT

Advantages Cantiliver Shafts are widely used for Pouching Machines, Doctoring Machines & Label Printing Machines. Cantiliver Shafts has a durable construction to hold the cores for the positive gripping. Cantiliver Shafts are in flange mounting styles and are used for light to medium duty works.

Type : Lugs / Multi-tube / Leaf

Length : Upto 1 Meter

...more

MULTI TUBE AIR EXPANDING SHAFT

Advantages Multi Tube Air Shaft provides superior performance for winding and unwinding process in all types of printing & packaging industries. Multi Tube Air Shaft features durable hard multi-bladder for gripping the inside diameter of any type of cores. Multi Tube Air Shaft can be run on multiple and large diameter cores. It gives and equalizes tension during working time.

Length : Upto 3.5 meters

...more

MULTI TUBE AIR CHUCKS

Multi Tube Air Chucks are used for all types of Slitter, Rotogravure, Flexographics, Rewinder and Winder Machines and it can be easily mounted on the Pneumatics/ Mechanical / Multi Tube Shaft. Multi Tube Air Chucks are having very light weight and it ensures safe use of cores without surface damage. Multi Tube Air Chucks have equal tension on each strip, load divide on each strip that’s why it has more life as compared to Bladder Type Air Chuck.

Type : Multi Tubes / Lugs

Warranty : 12 months for any manufacturing defects

...more

Mechanical Expanding Shaft

Advantages Mechanical Expanding Shaft delivers superior performance for Winding & Rewinding application in the widest range of roll handling process. Mechanical Expanding Shaft which does not need air pressure as it works manually. Mechanical Expanding Shaft has widest range from heavy to medium duty work.

Length : upto 3 meter

...more

MECHANICAL CORE HOLDING CHUCKS

Mechanical Core Holding Chucks are having superior performance and widely used at unwind & rewind operations of converting process. Mechanical Core Holding Chucks are having shaftless mechanism. Mechanical Core Holding Chucks don’t require pneumatics pressure because of spring loaded mechanism.

Warranty : 12 months for any manufacturing defects

Delivery time : Three to Four weeks

Delivery time : Ten Days

...more

Leaf Shaft

Leaf Shaft provides superior performance for winding and unwinding process in all types of converting industries. Leaf Shaft has widest range from heavy to light duty work. Leaf Shaft design prevents roll slippage during working period.

Size : 76mm, 101mm, 152 core ID

Length : Up to 2.5 meter

Air Pressure : 0 to 6 Bar

Warranty : 12 months for any manufacturing defects

...more

Ink Mixing Roller

Ink Mixer Roller is having very light weight and constructed in such a way to float in the ink tray and no ink can enter inside the roller

Length : upto 2 Meter

...more

Ink Circulation Pump

Ink circulation single diphragm pump operated by pneumatically operation. It has long life and prevents fire in converting industries. It is chemical resistant.

Warranty : 12 months any manufacturing defects

Application : Widely used in printing ink and adhensive circulation

...more

HEAVY DUTY MILL SHAFT

Advantages Heavy Duty Mill Shaft is manufactured for use in production of Jumbo Rolls Tissue and Paper Industry & Steel Industry. Heavy Duty Mill Shaft is manufactured in two types – Lugs Type or Multi Tube Type. Heavy Duty Mill Shafts are available in custom diameter & length. This shaft is dynamically balanced and precision ground & chromed to the most precise tolerance.

Length : Upto 3.5 meter

...more

Doctor Blade

CARBON STRIPS Common name: STEP EDGE. A standard blade for Rotogravure & Flexographic Printing and Coating application with solvent and water based inks. This is very commonly used. Made of carbon steel and microstructure blade, it is used at printing houses worldwide. The base steel material is made from genuine high quality European steel. Advantages High quality genuine Swedish and German steel Corrosion and wear resistance Low Anilox and gravure cylinder wear A refined microstructure with a denser carbide formation, compared to other basic carbon steel types This Blade gives Ultra Durable long Life for Printing etc.. Long lifetime and Gives Extra mileage. ROTO GRAVURE Proper Mounting and Usage of Mona + plus Doctor Blade on the printing press ensure that you get the longer life excellent wiping action from the doctor blade The blade holder must be clean at all times .No ink sedimentation between the Blade and the blade holder should be permitted Use a counter/support blade from 0,5mm thickness, preferably a stainless or CARBON Strips type Cut the counter/support blade at ends to 45 degree angle. (To reduce wear from printing cylinder ends) Make sure the doctor blade is mounted straight in holder, so no waviness is observed. Check along the blade from the side When bolts/screws are used for clamping blade holder, tighten from center bolt/screw and outwards crosswise. Use a torque-wrench if possible. Check so all treads are OK and that no bolts/screws are missing Use measuring tape or other precise measuring tool for setup of blade extensions. (Preferably use fixed end-stops/pins in bottom of the blade holder clamping area) Check doctor blade edge for damages by lightly running your finger nail along the blade edge. Be careful, it’s sharp! Attach the doctor blade holder securely to machine. Try to achieve a 55-65 degree contact angle between doctor blade and cylinder (less doctor blade pressure is needed) Use a blade pressure of 0,5-1,2 bar, increase more if there is no clean wipe, but try to use as low blade pressure as possible. (Less blade flex and blade/cylinder wear) Set blade oscillation to 20-30mm. If your machine doesn’t allow that long stroke, use the max stroke length. Make sure oscillation stroke is smooth. No jerks or stops If there is a need to use a slur-stick, use one with a very sharp tip. Then only low pressure force is needed. Recommended is to use a round wooden stick that can fit into a pencil sharpener for re-sharpening The support Blade must be clean and uniform the and should be mounted on top of the doctor blade as shown above figure . To permit flexibility and proper lubrication , the thickness of the support blade between 0,5 mm . The Distance between the doctor blade tip and the doctor blade tip should be between 3-5 mm . Flexo Settings Use a high quality doctor blade with dimensions suitable for your ink and anilox type. Check your doctor blade chamber/holder so it is straight, clean and without damages, especially in the clamping area If screws/bolts are used for clamping; make sure all screws/bolts are present and that threads are in good condition both on screw/bolt and in chamber/holder Make sure the doctor blade is mounted straight and that no waviness in the blade is observed If a chamber with end seals is used, let the doctor blade length reach 50-70% onto the seal width When screws/bolts are used for clamping chamber/holder, tighten from center and out crosswise Check so doctor blade extensions are correct Examine doctor blade edge for nicks by lightly running your finger nail along the blade edge. Be careful, it’s sharp! Attach the doctor blade chamber/holder securely to machine Check so your anilox roll is clean and in good condition Make sure chamber is aligned to anilox roll, both vertically and horizontally Apply lowest chamber/holder pressure needed (less doctor blade flex and blade/anilox wear). Only press so camber doesn’t leak and doctor blade wipe correctly at production speed.

...more

differential shafts

Advantages Differential Shaft is basically a rewinder shaft of slitting machine which can give consistent winding tension irrespective of film width. Differential Shafts are designed to provide the better degree of control to ensure multiple core gripping so that applications are performed correctly. The rewind reels can be easily removed by a small rotation on rewinding direction.

Length : Upto 3 meters

Application : Multiple slit on one time such as PET, CPP, OPP, PE, PS, PVC, FILM, FOIL etc.

...more

Chamber Doctor Blade and Corrugated Printing

Retrofit to your Corrugated printing machine by remove the existing rubber roller and replace with our Chamber doctor blade assembly. The system consist of hydro loading with Air/Oil converter and quick wash with double diaphragm pump that can change color to color with in 5 min. and save more water for washing. It is environment friendly equipment Advantages Save Ink, Varnish and Glue more than 30% Imrpove printing Quality and Machine efficiency Reduce Machine downtime and maintainance cost Eliminate Orange Peel and Scoring Line on the Anilox Roll

...more

Chamber Doctor Blade

Narrow Web Flexo Printing Retrofit to your narrow printing press such as Envenlop printing machine, Label printing and Flexible packaging printing machine Wind Web Flexo Printing Retrofit to your narrow printing press such as Envenlop printing machine, Label printing and Flexible packaging printing machine Mid Web Flexo Printing Machine The system consist of hydro loading with Air/Oil converter for high speed printing > 200 m/min and quick wash with double cube diaphragm pump that we can change color to color with in 5 min Advantages Save Ink, Varnish and Glue more than 30% Imrpove printing Quality and Machine efficiency Reduce Machine downtime and maintainance cost Eliminate Orange Peel and Scoring Line on the Anilox Roll

...more

Cantilever Shaft

Cantiliver Shafts are widely used for Pouching Machines, Doctoring Machines & Label Printing Machines. Cantiliver Shafts has a durable construction to hold the cores for the positive gripping. Cantiliver Shafts are in flange mounting styles and are used for light to medium duty works.

Type : Lugs / Leaf

Length : Upto 1 Meter

...more

Button Air Expanding Shaft

Advantages Button Air Expanding Shaft is one of the most popular and requested design shaft. It is suitable for a full range of converting and web production operation. Button Air Expanding Shaft rugged construction and design is available for any diameter or length, in steel or aluminum with special designs available for heavy duty and light weight applications. We manufacture to your specifications to suit your equipment, including standard or varied button spacing, cantilevered or custom designed.

Length : Upto 2 meter

...more

Anilox Chrome Roller

The Anilox roller has cells that carry a specific amount of ink to the plates, the number of cells per linear inch vary according to the type of print job. The higher Line Anilox Rollers will correlate with smaller BCM (Billions of Cubic Microns) Anilox Volumes. Note: The lower the BCM Volume, the stronger (more pigment) your ink must be/have to achieve density. With increased strength comes a decrease in printing properties, resistance properties, etc. Keep this in mind when putting together a job jacket. When selecting an Anilxo Roll, there are three main aspects to keep in mind. A.) The shape and angle of the cells (60º, 45º, 30º, etc.) B.) The carrying capacity of the cell (or cell volume BCM) C.) The number of cells per linear inch (or line screen) The amount of ink that is transferred from a cell depends upon the carrying capacity of the cell, or the Cells BCM Volume. Remember, you with a wet and fluid film of ink and it is important to keep in mind that you want to print with the thinnest ink film possible for each particular job. Thinner ink films are easier to control, reduce dot gain and increase graphic capabilities.

...more

AIR EXPANDING SHAFT REEL SHAFT

Air Expanding Shaft delivers superior performance for winding & rewinding application in the widest range of roll handling process. Our Air Expanding Shaft is one of the best core gripping having widest range from heavy to light duty work Air Expanding Shaft minimizes reel change over time. It does not lead to any harm at the core surface

Length : Upto 3.5 meters

...more

air expanding chucks

Advantages Air Expanding Chucks are based on shaftless mechanism and are mounted on the flange. Air Expanding Chucks are having superior design for light duty application in all types of converting industries.

Warranty : 12 months for any manufacturing defects/td>

...moreBe first to Rate

Rate ThisOpening Hours