Valve Test Stand

Paskals designs, manufactures and delivers valve test units for pressure testing any type of Gate, Globe, Plug, Ball, Check, Safety and Butterfly valve according to all international test standards. Capabilities: ♦ Range DN10 2200 mm. / ¼ - 86. ♦ Horizontal (stem vertical), vertical. (Stem horizontal) or tilting clamping system ♦ Clamping on the inlet flange, either flanges or (proportional clamping) between the clamping tables. ♦ 1 2000 tons of clamping force. ♦ With no or limited linear force on the valve body. ♦ Test pressure range: from vacuum up to 2000 bar / 30,000 PSI. ♦ Test medium: Liquid, compressed air, Nitrogen, Helium or Hydrogen.

...more

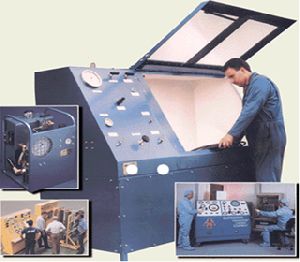

Test Benches For Valves

300,000 - 1,200,000 Per Piece

Type : Test Bench

Certification : CE Certified, ISO 9001:2008

Color : Black, Blue, Green, Orange.Grey, Red, Yellow

Voltage : 110V, 220V, 380V, 440V

Condition : New, Used

Automatic Grade : Manual, Semi Automatic

Driven Type : Electric

Warranty : 1year, 2years, 5years

...more

Servo Hydraulic Test Stands

Paskals offers an extensive line of systems for testing Linear, Servo and EHV, Pump and Motor, and Hydraulic Power Units providing our customers with the ability to test a wide range of hydraulic components on an aircraft. Paskals is host to an extensive test library covering a wide range of LRUs for manual, semi-automatic and automatic testing for both commercial and military applications.

...more

Safety Valve Test Rigs

Paskals designs, manufactures and delivers Safety (relief) valve test benches for set pressure measurement on all types of spring or pilot operated safety (relief) valves. General specification: ♦ Range ¼ -10 or ¼ -16. (Larger stations available on request). ♦ Low or high volume full lift testing. ♦ Stationary, skid mounted portable or containerized systems. ♦ Safety screen. ♦ Safety interlocks. ♦ API 527 test facility. ♦ Liquid test system with J-tube design. ♦ Test medium: Compressed air, Nitrogen or Liquid. Features: ♦ Windows operated Computer Registration System. ♦ Full automatic set pressure and leakage testing. ♦ Pneumatic or electric driven high pressure compressor and storage system. ♦ Set pressure detection system by lift and acoustic measuring. ♦ Adapters for male and female thread connections. ♦ Partly for fully closed safety closure. ♦ Separate of combined test facility for pressure vacuum (breather) valves.

...more

Refrigerant Recovery and Charging System

Paskals are specialists in the design, manufacturing, test & commissioning of standard and customized systems in a wide range of industries & applications. Our experience in high pressure gas pressurization and transfer has enabled us to develop our reputation for high pressure gas control technology. Typical Special Fluids Systems which Paskals can offer are: » Oxygen Test Rig » Oxygen Booster Systems » Oxygen Plant » CO2 Liquefied Gas Pumping System » Argon Charging Unit » Air Service Carts » Helium Charging System » Helium Decanting System » Helium Purification Systems » Halon transfer Unit » Vapor Mixing Systems » SF6 Recovery & Recharge Systems » Refrigerant Gas Recovery Systems » Refrigerant Charging Systems » Coolant Charging Systems » Nitrogen Generation Plants (PSATower) » CFC Charge & Recovery System

...more

CNG Vehicles testing Priority Panels

We Deign, Fabricate in House Customized Priority panels for Testing & Filling of CNG Vehicles. Priority Panels are designed around our own extremely reliable and robust Priority Valve. All components used in our panels are manufactured from high quality stainless steel SS316 (Swagelok) ensuring maximum corrosion resistance and a long service life. Before dispatch all Priority Panels are tested on natural gas at our in-house CNG station. This ensures that on arrival your priority panel is ready to use and no additional on-site adjustments are required. The clear benefits gained when you install a Priority Panel are: » Ultra High Flow Rates – The panels are designed for compressor flow rates in excess of 3,000 m³/hr » No Reverse Flow – The check valves on each line prevent reverse flow through the priority panel » Large Flow Range – The KG80 meter is accurate over the range 1-80kg/min and has been approved to the latest OIML standard: “Compressed Gaseous Fuel Measuring Systems for Vehicles”. Easy Maintenance – The station can be kept running while the manual isolation valves are shut for maintenance work. Pipework does not need to be removed for servicing the panels » Simple Operation – The Priority Valves only open once the inlet pressure reaches 230 bar. Gas is then allowed to flow to the common outlets on the bottom and right hand side of the valve. When all banks reach 230 bar, they fill up together until the compressor shuts off. We offer a range of Priority Panels with options designed to suit your specifications: » One, Two, and Three Bank Priority Panels » Optional Compressor Top-Up » Optional Solenoid Shut-off Valves » Optional Pressure Relief Valves » Daughter Station Priority Panel » Other options are available on request Solenoid Shut-off Option With the addition of Solenoid Valves each of the forecourt lines can be shut-off. The solenoids come pre-wired into a flameproof box and when the power supply is removed the solenoids close instantly. This additional safety feature provides increased control of the gas flow through your priority panel.

...more

High Pressure Generators

Paskals TestPAC is designed to provide on-site High Pressure testing, Hydrostatic Testing, Proof Pressure Testing, Burst Testing. These units are self-contained and powered by compressed Air. These units can generate Liquid Pressure up to 4000 bar * and for gases we have PressurePAC which can generate gas pressure up to 2000 bar*. ADVANTAGES Ability to stall at any pre determined pressure and holds this fixed pressure without consuming power or generating heat -No heat, flame or risk of spark -Infinitely variable cycling speed (flow rate) -No limit or adverse effect to continuous stop/start applications -Pump seals are self-lubricated requiring no external airline lubricator -Reliable, easy to maintain, compact and robust -Stainless Steel frame standard -Portable configuration

...more

Oxygen High Pressure Component Test System

Portable Oxygen Injection Systems Due to their legendary quality & reliability under the toughest worldwide conditions combined with excellent price quality ratio the compact line High pressure Low Flow & Low Pressure High Flow Oxygen Injection Packages (For Process Applications), from Paskals are first choice of Metallurgy, R&D, and Medical Professionals. MAJOR COMPONENTS* The Test Rig contains the following major Components:- ♦ Oxygen Valves ♦ Oxygen Pressure Reducing Regulators ♦ Oxygen Pressure gauges ♦ Oxygen Rota meter ♦ Flow Regulators ♦ Oxygen Reservoir ♦ Heat Chamber ♦ Fixtures and other miscellaneous items. STANDARD FOLLOWED * Oxygen is a fire hazard as it promotes Combustion. So we select standard product and Design procedure, are as like:- ♦ Cleanliness Level: For Oxygen Systems, we Use components (Cleaning & Packaging as per ASTM G93 Level (Swagelok Special Cleaning and Packaging-SC11). ♦ We propose to use Pressure Regulators with Built in relief Valves for further safety. ♦ Leak Proof: Swagelok components (Proposed) are leak tested and final assembly is also leak tested. ♦ We follow following standards in our design, Component selection and final assembly of the system: ♦ NFPA 53: Serious Oxygen System Fires ♦ ASTM G4/ASTM G 128: Fire Hazards in Oxygen Systems ♦ G88/ MNL36: Design Guidance for Oxygen Safety Systems *Please consult Factory for Further Details

...more

Oxygen Generator

PSA (Pressure Swing Adsorption) Technology a revolution in Non Cryogenic Air Separation and Oxygen Generation Technology uses special grade of ZMS (Zeolite Molecular Sieve). The compressed air is passed through a Twin Tower PSA module interconnected with automatic changeover valves. After passing through a Refrigerated Dryer air gets dried. Dried compressed air will now come in contact with bed of Zeolite molecular sieves (ZMS). Zeolite Molecular Sieves are special grade of adsorbant which have the property of preferential adsorption of nitrogen molecules. At a time one tower remains under nitrogen production cycle, whereas the other tower undergoes regeneration which is achieved through depressurization of the tower to atmospheric pressure. The outgoing oxygen gas is sent to a surge vessel where the minimum pressure will be maintained with the help of Back pressure Regulator. ATTRACTIVE FEATURES 1. Fully Automatic Operation requiring no special attention- Manless Operation 2. Generates Oxygen as and when required – Plug It, Switch On & Forget 3. Easy to install and maintain – Skid Mounted & precommissioned 4. Purity of Oxygen upto 93-95% can be achieved 5. PSA (Twin Tower Pressure Swing Adsorption) Based upto 150 NM3/hr 6. VPSA (Three Tower)For 150 Nm3/hr to 1500 Nm3/hr 7. VSA (Three Tower) For capacities more than 1500 Nm3/hr

...more

Nitrogen Generator

Technology The compressed air is passed through a Twin Tower PSA module interconnected with automatic changeover valves. At the bottom of PSA towers, Activated Alumina is provided which has tendency of adsorbing moisture from compressed air. After passing through this bed of Activated Alumina air gets dried. Supply of dry compressed air from this layer of desiccant (activated alumina) will be continuous without any interruption. Dried compressed air will now come in contact with bed of carbon molecular sieves (CMS). Carbon Molecular Sieves are special grade of adsorbant which have the property of preferential adsorption of oxygen molecules. At a time one tower remains under nitrogen production cycle, whereas the other tower undergoes regeneration which is achieved through depressurization of the tower to atmospheric pressure. The two towers of PSA modules are inter-connected with automatic changeover valves through pneumatic signal given by solenoid valve which in turn get the electrical signal from the timer provided in the control panel. The changeover time cycle will be 1 + 1 minute. The outgoing nitrogen gas is sent to a surge vessel where the minimum nitrogen pressure will be maintained with the help of Back pressure Regulator. The product nitrogen will now be sent to the consumer point through a pressure reducing valves at required pressure. Salient Features: 1. The PSA type gas generator is fully automatic and the gas of proper specification is made available within short period after start-up. 2. This type of gas generator does not require any fuel. 3. Since the feed stock for this gas generator is air, there is no problem like soot formation or presence of Co2 etc. – the common problem in fuel combustion based gas generator. 4. The gas generator is very compact requiring very small floor area. 5. Depending on the pressure in the nitrogen storage tank, the gas generator keeps running with ON/OFF operation like compressed air installation. Therefore, the gas generator would work only to the extent of meeting your gas requirement as and when needed.

...more

metering skids

Gas pressure regulating & metering skids are being supplied with gas filters, Isolation Valve, Meters, Safety Shut-off Valve & Regulating Valve. Ideal for individual industrial units and as a stand alone unit. Compact, efficient and easy to maintain. Natural Gas Metering Skids » Complete natural gas pressure regulating & metering skids are being supplied with gas filters, Isolation Valve, Meters, Safety Shut-off Valve & Regulating Valve. Ideal for individual industrial units and as a stand alone unit. Compact, efficient and easy to maintain.

...more

Hydrostatic Pressure Testing

Probably this is the most common usage for the TestPAC. This heading covers both “burst” and “proof” testing of components. There are a vast number of components that require pressure testing. These include such items as: Hose, Pipelines, Valves, Pressure Vessels, Gas Bottles, Boilers, Heat Exchangers, Accumulators, Fire Extinguishers, Turbines, Oil-Well Equipment, and many more. The mediums normally used in pressure testing are: water, water and soluble oil, or oil.

...more

Hydraulic Power Packs

We specialize in the manufacture of standard as well as custom – built hydraulic power packs. Utmost care is taken to ensure that Quality Standards are maintained throughout the manufacturing process. Our entire range of hydraulic power packs are painted with polyurethane paints, to avoid corrosion, effectively. This ensures Quality performance of our power packs under all climatic conditions, even in coastal areas, where the salt content is high in the atmosphere. Our eye for even the minutes detail ensures that only standard accessories such as suction strainers, filler breathers, Pressure gauges, Gauge isolators and return line fillers, etc., are used during the manufacturing process. Only high Quality pumps and valves of world-renowned brands like ATOS, REXROTH, VICKERS, etc., are used in these hydraulic power packs, always ensuring excellent performance. This commitment to maintaining Quality Standards ensures longevity and reliability of our systems. With such adherence to Quality standards it is no doubt, our range of hydraulic power packs have already made a name for themselves in this highly competitive field. We do manufacture standard and custom-built Hydraulic power packs. All our power packs are painted with polyurethane paints to avoid corrosion in an effective way. This gives us enough confidence to use our systems in seashore belts, where there will be lot of salt content in the atmosphere. All our systems are compulsorily provided with all standard accessories such as suction strainers, Filler breathers, Pressure Gauges, Gauge Isolators & Return line filters etc,. We use only Branded and high quality accessories to increase the reliability of our systems. The pumps and valves used in our system are of High quality and of International Brands like ATOS, REXROTH, VICKERS etc. We also supply power packs with TPM & POKA YOKA standards to our customer needs. HYDRAULICS SYSTEMS Hydraulic Power Pack » Custom Engineered Hydraulic Power Packs are supplied in variable ranges of Pressure & Flow depending on the end application. Customized Hydraulic Systems » We specialize in custom built special duty Hydraulic Systems for variable application in aerospace, defense, railways, dockyards, automotives& other Industries. Hydraulic Test Systems » Paskals is a leading supplier of high pressure hydraulic systems to the fluid power industry. Whether it be a system for powering hydraulic jacks in aircraft ground support, clamping in the machine tool industry, hydraulic presses in the automotive and tyre manufacturing industry or valve actuation in the Energy market, Paskals system can provide total solution for these applications. Valve Actuator Unit » Paskals supply customized valve actuator unit for testing all types of process control & safety relief valves to test its performance & other parameters with all embedded safety & controls with additional optional feature of manual operation or semi automatic or fully automatic operation. Portable Hydro Proofer » We supply customized portable hydro Proofer for hydro & Proof Testing of industrial equipments s per end requirement of customer. We offer Portable Hydro Proofer in a variety of ranges differ in pressure & flow with all embedded safety interlocks.

...more

Hose Leak Testing Machine

Paskals Design Custom Engineered Hose Test Equipment for the Automotive, Aerospace, Chemical, Industrial and Gas Industries. Specifications include: » Hose Mandrel Extraction System » Hose Proof Pressure Tester » Hose Pulse Tester » Hose Leak Tester » Hose Burst Pressure Test System They can be supplied with features that include: √ Data Acquisition √ Vibration √ Temperature Control & Environmental Chambers √ Flushing to Cleanliness Standards √ Automatic PLC Sequence Control √ Quick Clamping Mechanisms Typical hoses being tested include: √ Power Steering √ Air Conditioning √ Radiator √ Brake √ Aerospace Hose & Pipe work √ Industrial Hydraulic & Gas hoses.

...more

Helium Recovery and Charging Systems

The Helium Charging test unit consists of SS Enclosure, fitted with high pressure Gas Booster, designed with a control panel including all measuring & control instruments likely gauges, valves, regulators etc. Industrial Helium Cylinders are used to charge high pressure cylinders using air driven gas booster. Decanting operation is done to vent out remaining helium gas from cylinder before hydro testing is done to an empty cylinder using the same Gas Booster.

...more

hydraulic rig

Paskals Supply Custom Built General Purpose Hydraulic Rig for various performance test, loading test, cycling test, endurance test, cracking test, fatigue test etc with different Pressure, Flow & Temperature Parameters. General Purpose Hydraulic Rig can be designed for any configuration & any level of automation & Control can be incorporated.

...more

Gas Metering Skids and Trolleys

Pipeline metering applications require specialized skills to ensure the safe transportation and accurate measurement of petroleum products. Custom fabricated metering skids from Paskals are an ideal way to meet these objectives. Paskals metering skids are fabricated and assembled at Paskals facility. All welding is performed by certified welders and then tested per customer requirements. To further ensure weld integrity, all piping is also subjected to hydrostatic testing. The finished skids are delivered to the jobsite completely assembled, painted, and tested, resulting in considerable time and cost savings versus field fabrication.

...more

gas metering skids

50,000 - 150,000 Per Piece

Type : Metering Skid

Material : Iron, Stainless Steel

Certification : CE, ISO 9001:2008

Application : Industrial

Color : Black, Blue, White, Yellow

Voltage : 110V, 220V, 330V, 440V

Condition : New, Used

...more

Gas Filtration and Conditioning Stations

The purpose of gas conditioning units is to pre-treat natural gas and other combustible gasses prior to injecting them into a more critical process or a gas turbine generator. These units perform two functions: 1. Removal of all liquid droplets and solid contaminants from the gas, and, 2. Adjustment of the gas temperature to the injection requirements. Different styles of filter elements can be used in the pressure vessels. The liquid contaminants are collected in a sump and automatically drained from the system for easy operations. Either electric or steam heaters can be used for temperature adjustments. All system components and piping are skid-mounted for transport and installation. The proper removal of moisture and solid particles from the gas prior to critical usages will greatly improve the operation of the rotating equipment.

...more

gas control panels

Paskals manufactures a complete line of Custom Engineered gas control panels from basic gas selector panels, to gas selector control panels, to multiple gas mix panels.

...more

gas cabinet

Gas Cabinet enclosures are designed to dispense gases in a controlled manner and to protect from exposure to dangerous materials. The gas distribution cabinet protects these sensitive devices from external mechanical, chemical and heat effects.Gas cabinets are constructed to allow connecting proper forced ventilation to avoid accumulation of dangerous gases and vapors. Depending on the specific gas, additional design features are required in a gas cabinet (gas cylinder cabinet). Some of the features are: » Excess Flow Sensor » Gas Sensor » Sprinkler Head » Excess Pressure Sensing » Automatic Operation with Automatic Purging

...more

Gas Booster Stations

Attractive Features: » Pressure Decay & Differential Pressure Technology for Leak detection of Gas. » Single Point Operation » LCD Display of Operation » Fully Automatic function » Step pressurization (3 Stages) to 300 bar. » Precise Flow Control » Nitrogen Recycling/ Reuse » High Pressure Storage » Calibrated Rate of filling of the Test Volume » Independent programs for various Test Volumes (up to 5 Types) » High Pressure Gas safety Interlocking » Inbuilt Air & Nitrogen Filtration » Most desired product for mass Production setup (OEMs) » Printed test report & data entry of the test schedule » System will comply with poke yoke quality assurance.

...more

Fuel Injection Pump Test Rig

Paskals can supply fully automatic software controlled Fuel Injection Pump Test Rigs for performance & operational testing of pump at variable Pressure, Flow, Temperature& RPM ratings. The Test Rig comprises of Hydraulic Power Pack, Cooling Circuit, Lubrication Circuit and Gear Box with all measuring Instrumentation namely Pressure Transmitters, Flow meters, RTD’s etc with control & other safety features. Testing can be done at 120ºC using ATF.

...more

Flushing Skids

We are the main supplier of this product.

Type : Flushing Skids

Color : Red,Blue,Grey,Sky-Blue

Condition : New,Used

Power Source : Electric

Application : Industrial Usage

Pressure : High ,Low ,Medium

...moreBe first to Rate

Rate ThisOpening Hours