Plastic Washing Machine

Get Price Quote

The crushed plastic is sent to Plastic Washing Machine through Feed Screw Conveyors to Floating Washing Machine. The plastic is washed & lead Contents sinks to the bottom of machine, the plastic is simultaneously forwarded ahead to the hot washing machine. Then the plastic is taken out with the help of Screw Conveyor from other end & put up in centrifugal de-watering machine, the washed plastic is taken out with the blowing system through Blower. The washed clean plastic is then stored in a storage bunker from there the material can be stored in bins or sacks.

Efficient Single Screw Extruder

Get Price Quote

The Machine Advantages 1, intuitive understanding of wear parts 2, reduce the production cost 3, improve labor efficiency 4, high torque and high rotational speed 5, wide application range 6, high yield, high quality and high efficiency Applications 1. Pipe extrusion: suitable for pp-r pipe, PE gas pipe, PEX crosslinking, aluminous model multiple tubes, ABS pipe, PVC pipe, HDPE silicon core pipe and all kinds of co-extrusion composite tube. 2. Plate and sheet extrusion: suitable for PVC, PET, PS, PP, PC board profile and extrusion. Other all kinds of plastic extrusion, such as wire, rod, etc. 3. Profiles extrusion: adjust the screw extruder rotation speed and changing the structure can be applied to the production of PVC, polyolefins, etc. Various kinds of plastic different profile. Modified granulation: suitable for all kinds of plastic blending, modification, the increase of granulation.

Best Deals from Plastic Machine

Paper Film Converting Machine

Get Price Quote

Plastic Scrap Crusher Machine

75,000 Per unit

Plastic Crushing Machine

Get Price Quote

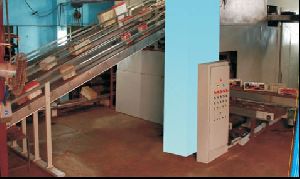

The shaved lid which is separated from under the welded straps is sent through conveyor to Lid Crusher Machine. Plastic parts are separated from the Lead parts. Such plastic parts are sent to the Plastic Crusher & are cut into smaller pieces. This machine is used to crush Battery Container made of Plastic Material. It crushes to small Pieces up to size of 1" square in one go and Washes Lead accumulated on it. It is shearing & hammering action increases its Power versus Output Ratio. Lead is precipitate on another conveyor. This conveyor conveys Lead Particles/ Pieces to one side. Plastic which can float on water will be filtered on another Conveyor. Plastic is fed to Plastic Washing Machine. This Plastic Washing Machine washes Plastic with Soap Solution. Plastic is filtered and collected. Water is used again after purification. Total Power: 56 H.P./42Kw. Container Feeding Conveyor: This conveyor is used for feeding Plastic Container to Plastic Crusher: M.S. material makes. The Drive of Electrical, 415V/380V, 3 Phases, 50Hz, 0.5 HP Crushed Plastic Feeding Conveyor: This conveyor is used for feeding crushed plastic to Plastic/ Lead Separation Machine; It is of MS material.