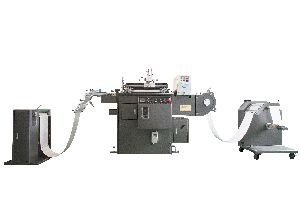

Roll to Roll Screen Printing Machine

2,500,000 - 4,500,000 Per Unit

1 Set (MOQ)

About Product Introducing a game-changing solution for label printing – the Roll To Roll Screen Printing Machine. This cutting-edge machine is designed to elevate your label production, delivering unmatched quality and versatility that set your labels apart from the rest. Additional information Key Features: Print Brilliance: Say goodbye to limitations. Our Screen-Printing Machine brings your label designs to life with vibrant colors, intricate details, and exceptional clarity that captivates the eye. Seamless Roll-to-Roll Operation: With effortless roll-to-roll functionality, our machine ensures smooth transitions and uninterrupted printing, allowing you to maintain high efficiency and maximize your output potential. Versatile Adaptability: From diverse label materials to various sizes and shapes, our machine adapts seamlessly. Experience flexibility that empowers you to bring your creative visions to life. Precision in Every Print: Whether it’s fine text or complex graphics, our machine guarantees precise printing results that match your design’s intricacy, ensuring consistent excellence with every roll. User-Friendly Excellence: Simplify your printing process with intuitive controls and user-friendly features. Experience reduced setup time and streamlined operations, empowering your team to achieve outstanding results. Built to Perform: Crafted with the highest quality materials and advanced engineering, our Screen-Printing Machine is built to withstand the demands of high-volume production, ensuring longevity and reliability. Transform Your Label Printing: Step into the future of label production with the Roll To Roll Screen Printing Machine. It’s more than a machine; it’s a catalyst for creativity and innovation that reshapes how you present your brand. Ready to redefine your label game? Contact us today to explore how the Roll To Roll Screen Printing Machine can revolutionize your printing operations. Precision, versatility, and creativity converge – with the Roll To Roll Screen Printing Machine.

Ice Cream Roll Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Rolling Machine

Jewellery Rolls

Get Price Quote

We are one of the prominent manufacturer, exporter, and supplier of elegant jewellery rolls. jewellery rolls helps a woman’s precious metals safe, organize, and most importantly, untangled when she is travelling, away from home or on holiday. The rolls are lined internally with a satin material and when opened, has an open compartment plus zipped pockets and a ring holder. It is available in various different sizes and color combinations. attributes : durableensures safetylatest designstrendy easily portable

Hot And Cold Rolling Machine

Get Price Quote

We offer a wide range of Hot & Cold Rolling Machine, manufactured as per the international standards. Using the advanced manufacturing process and facilities, we develop our Hot And Cold Rolling Machine, which also undergo metallurgical inspection for their accurate and precision working. Developed by experts, our Hot and Cold Rolling Machine reduces the scrap and ensure easy operation. The Hot Rolling Machine produces thinner cross sections and reduces the average grain size of a metal, while maintaining an equipped micro structure. With right blend of technology and experience, we successfully customize Hot and Cold Rolling Machine as per the client�s specifications at reasonable prices. Features Durable High performance Corrosion resistant Accurate functioning Underwent metallurgical inspection

Paper Roll Slitting Machine

Get Price Quote

UV Roller Coater Machine

300,000 Per Piece

Roll Rewinding Machine

Get Price Quote

steel re rolling mills

Get Price Quote

Ashoka Steel Plants Manufacturing unit is a part of Ashoka Group, Ashoka is capable to carry out the entire in house expertise to design, manufacturer, deliver and start optimum steel plant. The group has established itself in the area of complete heavy project management by offering a guaranteed single source solution provider right from feasibility study, designing of equipment by using newest versions of ProE and AutoCad, manufacturing through updated and latest quality oriented machines and erection & commissioning of plant. Ashoka Group undertakes turnkey jobs for supply of complete steel re rolling mills including design, manufacture, supply and erection & commissioning of the complete plant. Together with that we also manufacture and supply a wide range of machineries required in a steel plant. The Group supported by expert knowledge and technological competence in this matter. Our approach to building manufacturing steel plants is studied and evaluated in all aspects, to make sure that everything is carried out perfectly. We make certain that the plant will be setup with the maximum output versus input ratio for optimum performance. We export products, services, and expertise. We are the only steel plant manufacturer that is genuinely concerned about your success. Consult with us today and discover the ways on how we can benefit each other and build a beautiful partnership for life.

Plate Bending Rolls

Get Price Quote

Specifications of Plate Bending Machine: 1) Max. pre-rolling thickness:28mm-110mm 2) Max. rolling thickness:32mm-125mm 3) Width:3000mm-6000mm 4) Diameter of upper roller:590mm-990mm 5) Diameter of lower roller:340mm-600mm 6) Driven motor power:55kw-160kw 7) Oil press power:22kw-75kw 8) Moving power:11kw-37kw

Shrink Tunnel Machine For Roller Conveyor

90,000 Per Piece

Roll Forming Machines

Get Price Quote

Bar Thread rolling Machine

Get Price Quote

Knoxe machinery - we are one of the top manufacturing and supplying high precision, quality engineered bar thread rolling machine from india.

Tape Rolling Machine

Get Price Quote

Tape Rolling Machine, straw making machine, Corona Treater

Bar Straight Thread Rolling Machine

Get Price Quote

We are offering bar straight thread rolling machine. Features ; 1. Hgs-40 rib peeling and thread rolling machine is compact in structure, stable in operation, and has an automatic opening and closing mechanism for rib peeling. Cycle time is only 30 seconds to finish a threaded end. 2. Adopts cold thread rolling technology. Does not cut the rebar parent metal, the strength of rolled thread is much higher than the parent metal. 3. Widely used, is able to process rebar of grades ii and iii with diameters 16mm- 40mm. 4. Easy to operate, no skilled technicians required. 5. Economic, low investment for the equipment. 6. Threading saves at least 20% wastage of expensive rebars compared to the conventional splicing lap procedure.

lamination film rolls machines

Get Price Quote

lamination film rolls machines, Binding Machines, Currency Counting Machines

Wire Rolling Machine

Get Price Quote

Wire Rolling Machine, Wire Crimping Machine, Wire Wrapping Machine

Roll Marking Machine

Get Price Quote

Roll Marking Machine, residential house, custom sofa set

Rolling Machine

Get Price Quote

Rolling Machine, Machine Gears, milling machine gears, Super Variant Gears

Roll Forming Machine

Get Price Quote

Roll Forming Machine, deck sheet

Paper Plate roll

Get Price Quote

Paper Plate roll, MS Noodles Making Machine

Thread Rolling Machine

Get Price Quote

Thread Rolling Machine, Concrete Mixer, Industrial Lifts

Plate Rolling Machine

Get Price Quote

Plate Rolling Machine, Condensate Polishing Units, Supports Power Plant Spares

Roller Cutting Machine

Get Price Quote

Roller Cutting Machine, Die Mould, Fryums Extruder machine, rotary roaster

thread rolling machines

Get Price Quote

thread rolling machines, Tractor Linkage Parts, milling Machines

Lines Garbage Bag Rolls Making Machine

Get Price Quote

Lines Garbage Bag Rolls Making Machine, bottle cap making machine

Re-Bar Thread Rolling Machine

Get Price Quote

Re-Bar Thread Rolling Machine, Tower Cranes, Passenger Cum Material Hoists

steel re rolling mills

Get Price Quote

steel re rolling mills

roll form machine

Get Price Quote

roll form machine, Printed Pouches

Triple Roll Machine

Get Price Quote

Triple Roll Machine, Perfume Filling Machine, Cosmetic Plant, Attrition Mills