Tube Mill

Get Price Quote

Tube Mill as API stranded comprises of strip preparation, pipe forming, welding, cooling, sizing straightening, pipe cut-off unit and pipe take off unit. The strip first requires leveling and straightening which is done by passing the strip through strip leveler, pinch rolls and guide rolls. After this, the strip is passed through various forming rolls where the strips are converted into open seam pipe. Then it reaches the welding unit where the edges of the open seam tube are heated by HF induction generator (or any other welding equipment). Immediately after heating, the edges of the pipe are forged (fused) in the squeezing unit and it takes the shape of complete pipe. After welding, the welding portion is scrapped by bead scrapping unit then the tube is cooled in cooling jacket. For making it exact round the pipe is passed through sizing unit and then through Turks head for straightening. After this the tube is cut into required length by a moving cutting machine and pushed to take off table.

tube extrusion machines

Get Price Quote

Best Deals from Tube Mill

tube mills

Get Price Quote

Cnc Tube Bending Machine

1,900,000 Per Number

SS Tube Forming Mill

Get Price Quote

We provide tube forming mill for tubes of ASTM-Sanitary tube ASTM-312 Industrial pipe,ASTM-149 head exchange tube,JISG-3468 lorge diameter pipe and etc. Bright annealing Forming mill come with on line Bright annealing equipment gives bright annealing tubes for heat exchange,food/diary instrumentation’s industries application. Our stainless steel tube forming mill also come with in line bright annealing equipment’s and Ready current inspection equipment,inside bead rolling system .

Tube Expander

Get Price Quote

We offer best quality of tube expander to our clients...

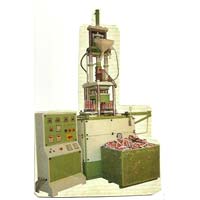

tube head forming machine

Get Price Quote

We are engaged in manufacturing and supplying quality Tube Head Forming Machine in Noida (Uttar Pradesh). Our Tube Head Forming Machine has high production capacity and is highly resistant to corrosion and wear and tear. We make sure that Tube Head Forming Machine is made in accordance with high industrial standards. We can provide Tube Head Forming Machine at reasonable prices. Details Production : 22000 Pieces/daySuitable To Make Tube Diameter : 13mm to 55mmPower Required : 7.5hp A.C 3 phaseHeaters : 750 watt � 3

Tube Bending Machine

Get Price Quote

Features: 1. Suitable for bending large diameter pipe, the angle from 0°to 180°can be adjusted randomly. 2. Technology can provide all types of pipe, the specification less than 8″is completed 3. Adopts hydraulic parallel integrate circuit, movement control is individual, so that the hydraulic components have a long life. 4. Three-section circuit, with cooling function, and even can make the hydraulic oil does not produce degeneration 5. spindle by thermal refining, bending hand forged by special steel, parts by stringent quality inspection, superior quality, unified specification 6. It has the function of both manual and automatic concurrently, and enclosed the emergency stop device. 7. Can be set various angles and mutual take turns bending, so avoid the trouble of transfer. 8. Host machine is controlled by electric equipment, even though unskilled worker can join the produce procession promptly, too. 9. Can equip automatic feeding length, set angle, finish complicated pipe and save manpower cost. 10. Automatic feeding length and feeding segment, and set variety of angle, according to consumer’s needs and productions.

Tube and Pipe Polishing Machine

Get Price Quote

Tube and Pipe Polishing Machine, pipe mill machine

Tube Mill

Get Price Quote

Tube Mill