Sheet End Welding Machine

Get Price Quote

Four Head Welding Machine

782,000 Per Units

1 Number (MOQ)

Best Deals from Welding Machinery

turning roll

500,000 Per Set

1 Set (MOQ)

TIG Welding Machine

Get Price Quote

1 Piece(s) (MOQ)

We are identified as one of the eminent TIG Welding Machine Manufacturers, Exporters and Suppliers based in India. Owing to their accurate working profile and unmatched quality, TIG Welding Machine offered by us is high on demand in national as well as international markets. Avail from us these TIG Welding Machines at industry leading prices.

Welding Torches

Get Price Quote

Available with us in different models, our Welding Torches are sturdy constructed and compact in size. We make use of top of the line quality metal and ultra-modern machines for their designing so as to enhance their quality and longevity. The Welding Torches, provided by us, are obtainable at market-leading prices. We are a celebrated Manufacturer and Supplier of Welding Torches in Uttar Pradesh, India.

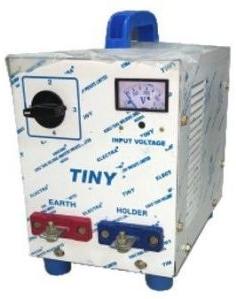

Welding Machine

Get Price Quote

We are one of the recognized Welding Machine Manufacturers and Suppliers in India. Capitalizing on our expertise, we offer the best quality Welding Machines to the clients. These Welding Machines are manufactured at par with the international quality standards ensuring magnificent performance. We make Welding Machines available at reasonable prices. Specialties Precision engineeredEasy to operateDurableOptimum qualityCorrosion resistantExcellent performance

Submerged arc welder

Get Price Quote

Clients can select any payment mode from our online or offline methods. Both of them are secure, hassle free, and ensure the fastest trade with the customers. Ours is a well-recognized organization based in New Delhi(India) and appreciated for offering products in the local markets.

welding controller

Get Price Quote

Inverter Battery Intercell Welding Machine

290,000 Per Units

Helmet Projection and Surface Friction Testing Machine

Get Price Quote

1 Piece (MOQ)

Welding Machine

Get Price Quote

From safety to quality, cost-efficiency, and performance, we offer the industry’s best Welding Machines with countless benefits to our clients spread all over the country. We are one of the trusted Manufacturers and Suppliers of Welding Machine from Uttar Pradesh, India. Our Machines pass stringent quality tests and get accreditation from various governing bodies. In addition, our Welding Machines continue performing optimally throughout the year irrespective of the prevailing climate. Furthermore, we possess enough competencies to even process the bulk order for Machines in short span. We offer Welding Machines in four different types: MIG, TIG, ARC, and SPOT.

stick welder

Get Price Quote

inverter welding machine

Get Price Quote

Welding Rods

Get Price Quote

solid state induction welders

Get Price Quote

Vibrating Screen

Get Price Quote

Offers vibrating screen. Continental wire industries is a prominent vibrating screen manufacturer & supplier based in india.

Intercell welding machine

240,000 Per Piece

1 Piece(s) (MOQ)

ppr pipe welding machine

Get Price Quote

We are one of the recognized PPR Pipe Welding Machine Manufacturers and Suppliers in India. Capitalizing on our expertise. We offer the best quality PPR Pipe Welding Machine to the clients. This PPR Pipe Welding Machine is manufactured at par with the international quality standards ensuring magnificent performance. We make PPR Pipe Welding Machine available at reasonable prices. Our product can be applied to thermoplastic pipes like Type 20-32 and so on. It has such fine characteristics as accurate control of temperature, safety and specialized Non-stuck plastics, easily operated by users. Major Technical standards Using Conditions : � 1000 meters (sea level)Environment Temperature : 200 C � 500 CRelative Humidity : 45% - 95%Limited Power : 220V; 50 ± 1 HZHeater Temperature : 260 ± 50 CSafety Standard : Insulating resistance � 1 M � Leak electricity � 5mA (AC effective) Specialties Precision engineeredEasy to operateDurablesOptimum qualityCorrosion resistantExcellent performance

InRow Chilled Water Cooling

Get Price Quote

Close-coupled, chilled water cooling for medium to large data centersExplore InRow RC in 3D animation.The InRow Chilled Water unit closely couples the cooling with the IT heat load. This prevents hot air recirculation, while improving cooling predictability and allowing for a pay as you grow environment. Available with and without humidity control, these products are intended to meet the diverse requirements for medium to large data centers. Data center operators looking to improve efficiency or deploy high density servers will benefit from the modular design of the InRow Chilled Water products. The intelligent controls of the InRow Chilled Water products actively adjust fan speed and chilled water flow to match the IT heat load to maximize efficiency and address the dynamic demands of today's IT environments. Serviceability Easy service access Allows for all serviceable components to be replaced/maintained by easily accessible panels/doors. Agility Casters Provides flexibility to move the unit to wherever cooling is required. Scaleable densities Allows for higher densities to be achieved by integrating containment with room, row and rack cooling system architectures. Modular design Modular design provides scalable solutions to add cooling as demand increases. Total Cost of Ownership Variable speed fans Variable speed fans reduce energy consumption during off-peak cooling periods. Row-based architecture Captures hot exhaust air directly from the IT equipment, thereby increasing the unit's sensible cooling capacity over traditional cooling architectures. Availability Dual A-B power inputs Draws power from the UPS for power protection with dual feeds for redundancy. Predictable cooling Placing the unit in the row of racks moves the source of cooling closer to the heat load. This eliminates air mixing and provides a predictable cooling architecture. Active response controls Monitors and actively adjusts cooling capacity to ensure proper server inlet temperatures. Through the microprocessor controller, visibility into the operation and health of the unit is provided. Top and bottom chilled water connections Allows chilled water to be connected from the top, if routing from overhead, or bottom, if on a raised floor. Rack inlet control Rack inlet control guarantees inlet temperature to IT equipment. Manageability Building management system integration Send alarms and data points allowing you to manage critical building infrastructure from a single system. Real-Time Capacity Monitoring Real-time display of current and available cooling. Microprocessor controller Provides proactive control and real-time monitoring via a four line, eighty character, alphanumeric display.

Exothermic Welding System

Get Price Quote

10 Piece (MOQ)

Electronic Welding Machine

Get Price Quote

We are one of the leading manufacturers and suppliers of a broad array of Electronic Welding Machines which are widely used in various industrial applications. Owing to their high durability and performance reliability, these machines are extensively demanded in various engineering industries. With the help of our quality personnel, we fabricate these machines using high grade raw material. Our valuable clients avail these welding machines in standard as well as customized specifications at very reasonable prices.

wire mesh welding machine

Get Price Quote

Vibrating Screen

Get Price Quote

Vibrating screen has such features as reliable structure, strong exciting force, high screening efficiency, low vibration noise, long service life, convenient repair and safe use, which can be widely used for the product classification in mine, building material, transportation, energy and chemistry. Vibrating screen is mainly composed of screening box, exciter, hanging device and electromotor. The electromotor drives the principal axis of the exciter to rotate through v-shaped belt, and under the centrifugal inertia force of the unbalanced materials on the exciter, the screen box will gain vibration and it can gain different vibration amplitudes through changing the eccentric block of the exciter. Vibrating Screen is primarily used for mining, metallurgy, building construction, road, railways etc.

electrofusion machine

126,000 Per Piece

Vibrating Screen

Get Price Quote

Vibrating screen has such features as reliable structure, strong exciting force, high screening efficiency, low vibration noise, long service life, convenient repair and safe use, which can be widely used for the product classification in mine, building material, transportation, energy and chemistry. Vibrating screen is mainly composed of screening box, exciter, hanging device and electromotor. The electromotor drives the principal axis of the exciter to rotate through v-shaped belt, and under the centrifugal inertia force of the unbalanced materials on the exciter, the screen box will gain vibration and it can gain different vibration amplitudes through changing the eccentric block of the exciter. Vibrating Screen is primarily used for mining, metallurgy, building construction, road, railways etc.

Induction Welders

Get Price Quote

Welding HOFR Cables

Get Price Quote

Welding HOFR Cables, HT and LT Stay Sets, Electric Cables

Hdpe Pipe Jointing Machine

Get Price Quote

Hdpe Pipe Jointing Machine, Injection Moulding Machines, Screw Barrel

Mig Mag Welding Machine

Get Price Quote

Mig Mag Welding Machine, inverter welding machine, Plasma Cutting Machine

double head welding machine

Get Price Quote

double head welding machine, Computer Numerical Control Cnc8065 T For Lathe