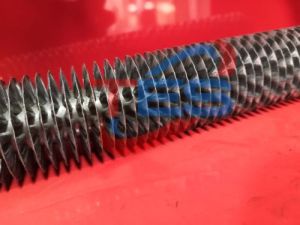

Copper Wire Wound Fin Tubes

Get Price Quote

100 Meter (MOQ)

Wire Wound Finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of wire wound finning tubes in lengths up to any length as long as it can be transported. We are manufacturers of wire wound finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper wire fins, stainless steel wire fins and GI (galvanized iron) fins. The base tubes of our standard wire wound fin tubes range from 3 mm to 120 mm with fin heights ranging from 3 mm to 40 mm. Wire Wound Fin tubing with higher fin heights can be made on demand. Wire wound fin tubes are used for making compact heat exchangers like air coolers, air cooled oil coolers, air heaters, air to air heat exchangers. Wire wound fins are formed with wire formed into a loop and the loops of wire are wound helically over the tube with simultaneous root soldering of the fins to the outer surface of the tube. The air flowing over the fin tube go round about the 'legs' of the fin loop causing immense turbulence. The root soldering eliminates almost all air gaps between the fins and the tube. This coupled with high turbulence results in high air side heat transfer coefficient. The air side heat transfer coefficient is highest as compared to any other type of fin tube for identical areas and parameters.Wire wound fin tubes for use in air cooled oil coolers are provided with internal fins selected from wide variations in configuration. We also manufacture double pipe wire wound fin tubes for use in refrigerated air dryers and heat exchangers for viscous and small streams.

Copper Fin Tubes

600 Per Kilogram

We are manufacturing Copper Fin Tubes and copper alloy fin tubes that are available in a wide range of options. Copper fin tubes find wide application in various power plant industries for a heat exchanger, condenser, and heat dissipation. Our Copper Fin Tubes are well-appreciated for their durability, strength, and perfect finish. They have a sturdy built and long operational life. Our Copper Fin Tubes are designed in accordance with the guidelines laid down by the market. Moreover, our clients are pleased with the availability of Copper Fin tubes at nominal prices.

Best Deals from Copper Finned Tubes

Spiral Finned Tubes

200 - 500 Per Per piy

50 Piece (MOQ)

Copper Finned Tubes

Get Price Quote

Fabricated using certified grades of copper procured from authentic vendors, Copper Finned Tubes offered by us comply with international standards of quality. The end products are sent to our advanced quality testing facility to ensure flawlessness of the entire range of finned tubes. Customised copper finned tubes made available by us have helped us in catering to the individual requirements of clients. Certain quality attributes of these tubes are as follows: Excellent finish Corrosion resistance Durability

Copper Finned Tubes

3,400 Per Piece

250 Piece (MOQ)

Copper Finned Tubes

800 Per kg

100 kg (MOQ)

INTEGRALLY FINNED – TURBO CHILL TUBES/STRAIGHT FINNED - TURBO CHILL TUBES Turbo Chill Tubes in straight form are available in various metals like: copper, cupro-nickel (70:30, 90:10), admiralty brass, aluminium-brass, aluminium, etc. Turbo chill tubes in straight form are manufactured out of: 15.875 mm and 19.05 mm OD tubes WIDTH: 11 fins per inch (fpi), 13 fpi,14 fpi, 15 fpi, 16 fpi, 19 fpi, 23 fpi, 26 fpi, 28 fpi, 30 fpi & 40 fpi, having fin height ranging from 0.889 mm up to 4.00 mm. Turbo-chill tubes can be manufactured up to a maximum length of 20 meters, with any number of intermediate landings (plain portion) for baffle supports, in addition to side landings. Multi Alloys International Specializes in the production of various types of finned tubes applicable in heating or cooling transfer systems. We have gained great reputation from our clients due to our stringent quality control standards and constant product innovations. Finned tubes are available in straight length with plain end on both sides and also available with interim skip, as per requirement. Fin tubes get improved heat transfer over plain tubes, thus allowing reduction in size and weight of the heat exchanger and condensers.

Finned Copper Tubes

Get Price Quote

We have reliable, legal, and secure payment procedures through which clients can make purchases. We maintain a high level of transparency and ensure to maintain proper documentation. Thanks to our immense expertise in this domain that allows us to deliver nothing short of the best quality Copper Fin Tubes. We offer its customers a range of competitively priced, assured quality of Copper Fin Tubes complying with the latest specifications. Finned Copper Tubes are manufactured in straight length and are characterized by high dimensional accuracy and excellent surface finish. The half hard tubes can easily be flanged and expanded. Most critical sizes of Finned copper tubes which require closure dimensional control with specified mechanical properties and surface finish can be manufactured through careful and constant monitoring of the processes at every stage of the production. Because of their wide material and size range copper alloy tubes are widely used in almost all fields of industry.

Copper Alloy Fin Tubes

Get Price Quote

We are an esteemed manufacturer, exporter and supplier of Supreme quality Copper Alloy Fin Tubes from Mumbai, Maharashtra. We offer Low finned Tubes and Enhanced Surface Finned Tubes with 19 & 26 fins per inch respectively. The products comprises of alloys of Alloys Copper, Copper, Nickel 95/5, 90/10, 70/30 Admiralty Brass Aluminum Brass. Available with Quality Control Chemical analysis as per specifications, these Copper Alloy Fin tubes are used in Heat Exchangers, Condensers & Chillers Condensers and General Heat Exchanging Units. As one of the reputed suppliers of this industry, we undertake bulk orders also.

Copper Finned Tubes

Get Price Quote

Carrying out systematic quality process at every stage, we keep our quality standards high to gain customers' satisfaction. We have a good rapport with the leading names in the industry from whom we source the basic material, required for manufacturing superior grades products.

Copper Alloys Finned Tubes

750 Per Kilogram

100 kg (MOQ)

We are offering copper alloys finned tubes. turbo chill tubes in straight form are available in various metals like: copper, cupro-nickel (70:30, 90:10), admiralty brass, aluminium-brass, aluminium, etc. turbo chill tubes in straight form are manufactured out of: 15.875 mm and 19.05 mm od tubes. width: 1) 11 fins per inch (fpi), 13 fpi,14 fpi, 15 fpi, 16 fpi, 19 fpi, 23 fpi, 26 fpi, 28 fpi, 30 fpi & 40 fpi, having fin height ranging from 0.889 mm up to 4.00 mm. 2) turbo-chill tubes can be manufactured up to a maximum length of 20 meters, with any number of intermediate landings (plain portion) for baffle supports, in addition to side landings. indigo metalloys specializes in the production of various types of finned tubes applicable in heating or cooling transfer systems. we have gained great reputation from our clients due to our stringent quality control standards and constant product innovations. finned tubes are available in straight length with plain end on both sides and also available with interim skip, as per requirement. fin tubes get improved heat transfer over plain tubes, thus allowing reduction in size and weight of the heat exchanger and condensers.

Copper Finned Tubes

Get Price Quote

Copper finned tubes Instead of smooth tubes. The corrugation generates high turbulence in Media, Vastly enhancing Heat Transfer co-efficient for a given Reynolds number. Copper & Cupro Nickel Fin tubes offers more surface area compared to plain tubes& increases heat exchange capacity of the tubes. Fin tubes are manufactured as per the customer’s specific requirements. We have the skill & necessary know-how for the production of integrated fin tubes & can manufacture the same as per your requirements.

Copper Finned Tubes

Get Price Quote

Copper Finned Tubes, that we offer, enable improved heat transfer over plain tubes, thus allowing reduction in size and weight of the heat exchangers and condensers. Copper Finned Tubes are available in straight length with plain end on both sides and also available with interim skip, as per customer design and requirements. Our Copper Finned Tubes are available in either 19 fins per inch or 26 fins per inch. The Copper Finned Tubes offered by us are extensively used in API heat exchangers and for applications like heat exchanging in commercial units for cooling and heating of liquid and gas, including water, oil, steam and air as well as for condensation, evaporation etc. Specifications Outer Diameter : 15.80 mm to 19.05 mmWall Thickness : 1.20 mm to 1.62 mmUnit Length : Up to 3mTemper : QH (Quarter Hard)

Copper Finned Tubes

Get Price Quote

Integral medium high fin tubes are available in copper with or without internal spiral ridges. These medium high fin tubes are manufactured out of:15.875mm, 19.05mm, 22mm, 25.4mm, 31.75mm & 38.10mm od tubes.

Copper and Brass Finned Tubes

Get Price Quote

Extruded Copper Fin Tube for Cooler

Get Price Quote

Copper Finned Tubes

Get Price Quote

Copper and copper-nickel alloys have a high natural resistance to biofouling relative to alternative materials. Copper Heat Exchangers has been proven over many years in sea water pipework and other marine applications. Copper Heat Exchangers alloys resist biofouling in open seas where they do not allow microbial slime to build up and support macrofouling. Some other metals used in heat exchangers, such as steel, titanium and aluminium, foul readily. Protection against biofouling, particularly in marine structures, can be accomplished over long periods of time with copper metals.

Copper Finned Tubes

Get Price Quote

Wire wound fin tube consists of a base tube with oval or near rectangular loops formed of wire which are wound helically over the tube with root soldering of foot of every loop to the tube. - The loop of wire creates greater turbulence thereby increasing the heat transfer coefficient. Root soldering along the entire length eliminates almost all air gaps between the fin and the tube. - For most applications, wire wound fin tubes make it possible to design a much compact heat exchanger coupled with lower pressure drop compared to conventional fin tube.

Copper Finned Tube

Get Price Quote

Copper Finned Tube

1,063 Per Kilogram

Copper Finned Tubes

Get Price Quote

Fabricated using certified grades of copper procured from authentic vendors, Copper Finned Tubes offered by us comply with international standards of quality. The end products are sent to our advanced quality testing facility to ensure flawlessness of the entire range of finned tubes. Customised copper finned tubes made available by us have helped us in catering to the individual requirements of clients. Certain quality attributes of these tubes are as follows: Excellent finish Corrosion resistance Durability