pellet mills

pellet mill dies

PMI Dies Buy superior die to ensure saving in electrical power, more tonnage per hour, sound of pellets less down time of pelleting press. Dies are exclusively manufacture to customer specification production and services are standard though knowledge of raw material and innovative technology are entirely pressed in to service of the client who feels himself fully supported by the first rate technical assistance. Dies are guaranteed to result in trouble free production high quality pellets, Dies are produced in a variety of alloy material and in different grades of alloy steels, It is produced as per specification a good type of materials and hardening process to ensure optimum die life. Have right manufacturing process as with die material PMI has to it's disposal a number of manufacturing process to the customer’s specific application Quality Control: to assure the strictest adherence to quality standard of all die machining, drilling, Heat Treating and polishing operation are conducted in house providing leadership in today's die technology in INDIA

...more

pellet crumbler

Motor Control Center

Totally enclosed dust proof sheet metal motor control for motors. MCC will have necessary starter al bus bar, fuses push-button and indicating lamps with incoming feeder with ammeter voltmeter, DOL starter up to 7.5 Hp motors and star-delta starter for large motor. Mimic Diagram as per requirement, User friendly Control desk, Bottom cable entry stand alone add on type front access.

...more

Fully Automatic Pellet Mill

full circle hammer mill

Fish Feed Pellet Making Mill

Condition : New

Color : All

feed mill plant

Electronic Batching System

To produce desired quality feed, perfect handling of ingredients is must. Every batch weighing application is unique with its own capacity requirements, place specifications, our batching system has proven this need by all technical aspects, even is auto on manual control system with semi auto control and it is user friendly. The plant mimic on the PC screen displays the status of the batching section & operations can be continuously monitored. PLC based computerized batching system. Software acquires various data & reports from the machines; quantity of the material in batch hopper is sensed by load cells & transmits the information to PC which controls the batching operations as per the recipe.

...more

Double Shaft Paddle Mixer

PMI mixer is used to mix the required quantity of molasses or other liquid ingredients in premixed batches its horizontal design ensures that the mix coming out is of uniform composition and free form lumps or balls, the capacity of mixer ranges from 2 tons per hour 4 to 10 tons per hours

...more

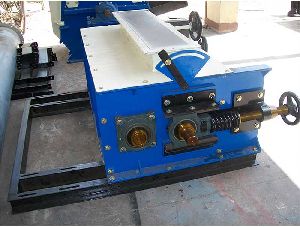

crumbler machine

The pellet crumbler is essential equipment for the preparations of crumbled pellet feed this is used for breaking the pellets into crumbs required for chicks which are 2-3 week old, pellet are broken in to pieces of the required size between the two roll of the crumbler. The gap between the rolls can be adjusted to regulate the size of crumbs. The crumbler is fitted with the drive parts which include and driven pulley, belt guard, and slide rails for motor.

Type : Automatic

Certification : CE Certified

Weight : 400-500kg

Voltage : 380V

Power : 1-3kw

Driven Type : Electric

Warranty : 1 Year

...more

cattle feed plant machinery

We are a prominent organization, which is engaged in manufacturing, supplying and exporting superior quality Cattle Feed Blender. Our offered blenders are especially demanded in the domestic sector. These blenders are designed by our skilled and experienced engineers by employing modern method and latest technology. Our organization makes sure to offer these blenders in different capacities and specifications. Customers can avail this Cattle Feed Blender from us at market leading prices. Features: Easy Maintenance Lower Operational Cost Application Specific Design Rigid Construction Longer Serving Life

...more

Bio Mass Pellet Plant Machinery

Biomass pellet plant fully adopts mechanical driven. It connects a series pellet processing equipments together to realize continuous pelletizing with easier operation and higher pellets yield. The biomass pellet plant is able to process a great many of biomass raw materials, such as woods, wood shavings, sawdust, EFB (palm kernel), coconut shell (coconut husk), coconut tree, bagasse, straw, rice husk, coffee husk, grass, etc. Less land space, saving, wide application range. Depending on our years of experience, we divide biomass pellet plant into 3 types: small pellet plant of 200-700kg/h mobile pellet plant of 250-350kg/h large pellet plant of 1-6ton/h The complete 0.5-10ton/h biomass pellet plant (with ring die pellet machine) from chipping to packing is CE certified by SGS. A complete biomass pellet plant, from biomass raw material processing to final packing biomass particles, includes crushing, drying, pelletizing, cooling and packaging processes. We break down the process into three parts: Material handling system (including wood chipper, hammer mill, dryer) Granulating system (ring die pellet machine) Packaging system (cooling and packaging)

...more

Belt Bucket Elevator

batch mixer

auto batching system

aspiration system

air blast assembly

Electric Blowers

Chain Conveyor

counter current cooler

Dust Collectors

Food Processing Equipment

rotary valve

Be first to Rate

Rate ThisOpening Hours