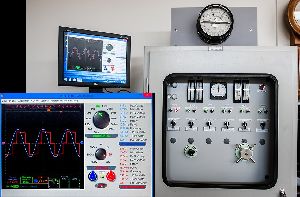

Synchronizing Panel

Synchronizing panel will operate on an automatic mains failure system, so that when the main supply is interrupted on one or all phases (after an adjustable delay period) the generator sets will start-up together. After an initial warm-up period (adjustable) the generators will synchronize with each other by means of motorized circuit breakers or contactors onto a common busbar. Next, the motorized change-over switch will be closed and the load will be connected to the main distribution box. The load share units continuously monitor the load and during low demand periods one or two generators will be shut down to save on fuel consumption. As demand rises again the second generator and third generator will be restarted, synchronized and reconnected to the load. When the AMF control unit detects that the main supply has been restored an adjustable observation period is activated before the main supply is reconnected. A cool down period will then follow, after which the generator sets will be shut down. Key features of Synchronization Panel Various combinations of load transfer by ACBs, MCCBs or Contactors Load sharing/load shedding Automatic and manual synchronizing Factory built to client’s specifications Control functions available for engine monitoring, warm-up and cool down periods, emergency shutdown, multi attempt engine start control, engine test runs

...more

Slip Rings

L&S supply high-technology Slip Rings for a wide variety of applications. As a recognized and trusted supplier, L&S can offer compact, reduced-size, or maintenance-free Slip Rings capable of operation in all environments. These innovative Slip Rings are suitable for helicopters, battle tanks, infantry vehicles, submarines, radar, wind turbines, nuclear, oil and gas, and other industrial Slip Rings such as for the food and beverage sector. L&S is a major supplier of standard and highly-customized Slip Rings to meet specific customer requirements for the transmission of power, data, optical and RF signals, including contactless solutions, pneumatic couplings, and fiber optic rotary joints. We also manufacture slip rings for high-speed data transfer or for data transfer in EMI sensitive environments. The main priority of L&S is to ensure the highest Slip Ring quality level, along with a full commitment to customer support. If you do not see a slip ring to match your requirements, please contact us for assistance. Our slip rings are aggressively priced, available for fast delivery and are designed for tough environments We are capable to supply Mercury wetted sip rings, Pancake slip rings and wireless slip rings. Few other common name of slip rings are collector ring, rotary electrical contact and electrical slip ring, commutator.

...more

Resin Cast Current Transformer

Indoor Panel Mounting Application Voltage Class: 6.6KV to 22KV. Secondary Voltage PT: 110V / v3 or 110V Manufacturing as per IS & IEC standards. Primary Current, Accuracy Class, Burden and Number of Secondary Cores / Winding as Specified.

...more

Protection Panel

L&S in providing power system protection panels and cubicles for all levels of electrical power transmission, distribution and generation, whether to electrical utilities, renewable installations, industrial sites or the transport sector. Protection panels generally have Relays, selector switches and test links/MCBs on the front Power supplies, auxiliary relays and dropping resistors mounted internally Terminal rails where all the externally connected wiring is wired out Benefits Plug-and-Play commissioning of the protection scheme, since it has been fully factory tested out to the terminal rails Minimum outage time and site-work cost

...more

Power Plant Automation

Power is one of the most important requisites for infrastructure development and therefore, is directly linked to economic growth of nations. The Indian power sector is quite diversified and comprises of Thermal, Hydro, Nuclear and Renewables sources for generation of Power. Development of adequate power infrastructure is essential to meet the growing demand-supply gap and sustained growth of the Indian economy. The sector throws good opportunity to build new plants, renovating old plants to enhance efficiency and to improve transmission and distribution system. We at L&S offer comprehensive solution to Power Gen segment for the Electrical and C&I needs. We have an experience base of providing such solutions to power Generation plants covering Unit size of 15 MW to 880 MW.

...more

Low Tension Current Transformer

Ring Type and Wound Primary Type for Panel Mounting Application Resin Cast, Tape Wound, Plastic Moulded Type. Manufacturing as per IS & IEC standards. Primary Current, Secondary Current, Accuracy Class and Burden as Specified.

...more

EXCITATION TRANSFORMER

Excitation transformers are use to magnetize generators and synchronous motors. Excitation transformers are a main component of any electrical system and its failure can cause the black out of the system. It is therefore important to make the right selection of transformer. We are well-known excitation transformer suppliers. Our excitation transformers are designed and manufactured to withstand the electrical and mechanical load stress. We make sure that our customers get reliable transformers designed, manufactured and tested for suitable applications. Key features of L&S Excitation transformers are Cooling Methods AN, AN/AF, ANAN Class of insulation B, F & H Ingress protection IP23, IP31, IP43 Interfacing bus duct design on Primary connection

...more

Digital Excitation System

L&S Automatic Voltage Regulator designed to protect your system against electrical brownouts, sags, surges, transients, and other electrical disturbances. It has a small overall footprint, high-efficiency design, and power quality monitoring. This automatic voltage regulator utilizes solid-state microprocessor based regulation for Hydro, Thermal gas based and other application power plants from 1 MW to 880 MW Generators. Applications: Hydro Power plants Thermal Power plants Gas Based Power plants Diesel Based Power plants. Synchronous Motors Marine base application Aircraft Application Benefits: Solid-State Topology Precision Voltage Regulation Control & Fault Monitoring PWM Inverter & Rectifier Integrated Quiet Design Vertical Configuration Extended Voltage Range As the use of power increases in our communities, utility companies have less and less control over the quality of power supplied to sensitive electronic equipment. The effects of unreliable power can cause irrecoverable damage to expensive manufacturing equipment, resulting in lost production time and/or products. Furthermore, the low output impedance of the transformer assures computer grade performance with excellent noise and transient attenuation. The automatic voltage regulator has 7 taps per phase, as well as, electronic switches to ensure tight voltage regulation to within +/- 3%. L&S AVR is a high-efficiency design, which results in a lower operating cost. Sizes are available from 10 to 1000kVA. Optional internal manual bypass maintains the system isolation, voltage transformation, and power conditioning. The function of the Automatic Voltage Regulator (AVR) is to maintain constant voltage and power line conditioning to the equipment load under a wide variety of conditions, even when the utility input voltage, frequency or system load vary widely. The AVR shall consist of an all copper, multiple tapped, triple shielded isolation transformer and contain independently controlled inverse parallel electronic switches for each of the 7 taps per phase to provide tight voltage regulation. The phase current shall be monitored for zero current recognition to initiate any required tap change. Linear devices shall be used for line synchronization to prevent phase shift errors normally associated with simple CT zero current crossing acquisition. The system shall be microprocessor controlled.

...more

Carbon Brush

L&S offers a wide range of carbon brushes for all types of Motors, Generators & Alternators, Grounding Devices and current & signal transmission. Our electrical carbon brushes are made from low friction conductive carbon materials including copper graphite, silver graphite, natural graphite, electro graphite, resin bonded carbon and pitch bonded carbon. The combination of this wide range of specialist materials and our highly experienced local technical support network allows us to match brushes and holders to customer equipment for optimum performance with minimal maintenance requirements. Selecting the correct grade carbon brush is important for commutator performance, maximum brush life, and high motor performance. We manufacture and design many patterns, grades and types of carbon brushes ensuring the correct carbon brush is available to meet your requirements for your motors or generators, and advice on carbon brush grade selection is given by our technical experts. The benefits to our customers include carbon brushes that can increase uptime and reduce maintenance costs by improving machine reliability and availability.

...more

Printed Packaging Box

Pulses

Washing Powder

Electrical

Be first to Rate

Rate ThisOpening Hours