Steel Shots

Get Price Quote

1 Ton (MOQ)

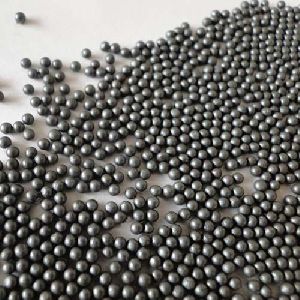

Steel Shot Steel Shot refers to spherical grain made of molten steel through an atomization (granulation) process, available in different sizes and hardness. Metal working industries are main users of steel shot such as ferrous and non ferrous foundries, steel mills, forging industries and sand removal to improve the metal surface preparation. With our quality we serve various industries like Automotive, Metallurgy, Aerospace and Petroleum Industries. Steel Shot is a general-purpose manufactured abrasive used to remove mill scale and molding sand. Its round shape cleans by hammering the surface, leaving a uniform surface profile. Steel Shot is most commonly used in wheel blast equipment and closed circuit blast systems for steel plate blasting, cleaning castings and forgings, and ship and railcar manufacturing and maintenance. With our quality we serve various industries like Automotive, Metallurgy, Aerospace and Petroleum Industries. STEEL SHOT complies to SAE specification J444 and J827 as well as IS 4606 of 1983. Chemical Composition -- Carbon: 0.80 - 1.20 % -- Silicon: > 0.40 % -- Manganese: 0.35 - 1.20 % -- Phosphorus: < 0.050% -- Sulphur: < 0.050% General Appearance Steel Shot shall be as nearly spherical Micro Structure The micro structure of steel shot shall be uniform martensite, tempered to a degree consistent with the hardness range with fine well distributed carbides if any. Hardness - SAE standard -40-50 Hrc (Rockwell Hardness) - IS Standard - 400 -500 HV ( Vickers Hardness ) - Custom Hardness available on request Density -Not less than 7.0 g/cc

Stainless Steel Cut Wire Shot

210 - 215 Per Kilogram

100 Kilogram (MOQ)

Best Deals from Steel Shot

Stainless Steel Cut Wire Shots

Get Price Quote

Stainless Steel cut wire shot is a cylindrical piece made from various grades of SS wire by cutting into small pieces. It is available in rounder shape called Conditioned Stainless Steel Cut Wire Shots. It is used for shot blasting of Aluminium and Gunmetal parts to remove sand or scaling over it or to get mat finish on the part surface.

steel cut wire shots

55 - 95 Per Kilogram

100 Kilogram (MOQ)

STAINLESS STEEL CUT WIRE SHOTS No Ferrous Contamination: Ideal for blasting or peening stainless steel, titanium, aluminum, or other non-ferrous work objects; Increased Production: High reusability Rate: over 800 operating cycles, perfect for Blasting Rooms; Certified Product: MIL-S 13165C, SAE J441, AMS 2431/4; No Dust. Available in conditioned form with certification to meet: MIL-S 13165C: Military Specification 13165C - Shot Peening of Metal Parts; SAE J441: Society of Automotive Engineers J441 - Cut Wire Shot; AMS 2431/4: Aerospace Specification 2431/4 - Peening Media (AWS), Conditioned Stainless Steel Cut Wire Shot; Stainless steel cut wire shot with bright surface that are used for shot blasting, shot peering and deburring in non-ferrous metal and stainless steel products surface. The surface of work-pieces are smooth, no rust and highlight metallic luster after process. Applications: Prevents ferrous contamination when blasting or peening stainless steel, titanium, aluminum, or other non-ferrous work objects. The economic case for using stainless cut wire shot in peening and blast cleaning operations is quite easy to make: cut wire does not fracture or break down during use because it is a solid piece. Stainless Steel Cut Wire is made by cutting stainless steel wire into pellets, the length equal to the diameter of the wire. SUPERIOR QUALITY PRODUCT Our stainless steel cut wire shots offer the following advantages: Produces very bright surfaces and dust free surfaces Stainless steel cut wire shot has a significantly longer life than cast abrasives and carbon cut wire shot Dust generation is significantly lower – blasting operations are much cleaner Stainless steel cut wire shot produces excellent results because of its uniformity and strength It will make you a “Greener” organization because disposal of spent media will be significantly reduced (you won’t need as much shot, inventory requirements will be lower, and inbound freight will cost less.) You will NOT introduce ferrous contamination to non-ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot No hollow, splits or twins STAINLESS STEEL CUT WIRE SHOTS APPLICATION . Surface finishing Obtain profile pattern Shot peening Shot blasting Our stainless steel cut wire shots is used in all impact treatments: Grit removal Pre treatment Rust removal Blast cleaning

high carbon steel cut wire shot

90 - 130 Per Kilogram

100 Kilogram (MOQ)

stainless steel shots

Get Price Quote

Stainless Steel Shot is produced by melting Stainless Steel Scrap of different grades. The product is mainly used for surface treatment of copper workpiece, aluminum workpiece, zinc workpiece, stainless steel workpieces and so on. It is also used in removing sand and cleaning foundry castings, De-scaling metal sheets, billets and profiles in the steel industries.

202 Stainless Steel Shots

100 Per Kilogram

200 Kilogram (MOQ)

Steel Shots

45 Per Kilogram

100 Kilogram (MOQ)

Steel Shots

82 Per Kilogram

Stainless Steel Shot

Get Price Quote

10 Kilogram (MOQ)

Stainless steel shot we are one of the leading manufacturers, exporters and suppliers of stainless steel shot. Stainless steel shot is produced by melting stainless steel scrap of different grades like 410, 430, 202 & 304 in the induction furnace. We are instrumental in offering superior quality stainless steel shots to our prestigious clients. Stainless steel shots used in an increasing number of important applications where ferrous contamination in blasting stainless steel, titanium, aluminum, or other non ferrous work objects could be harmful. Manufactured and sized to sae standards and specifications. We are recognized as a prominent trader, distributor and supplier of stainless steel, ferrous powder, non ferrous powder, copper powder, etc. Clients can avail a qualitative range of stainless steel shots. These products are manufactured as per sae standards and specifications. Our range is widely used in peening critical aircraft, automotive components, surface preparation of stainless steel and non ferrous components. Our cost effective range removes ceramic residue from investment castings, deburring and surface finishing of aluminium dia castings. These products are in huge demand in stainless steel and aluminium foundries.

steel cut wire shots

Get Price Quote

We are counted amongst the prominent stainless steel Cut Wire Shot Suppliers in India. Cut Wire Shots are made of cold drawn steel wire are obtained by cutting wire into lengths equal to the wire diameter, and then making it round, if necessary through the conditioning (rounding) process. The quality is assured in cut wire shot because the wire from which it has been manufactured, is heat treated and cold drawn to achieve hardness and homogeneity. A distinct advantage is that the Cut wire shots do not fracture, break or powder while in use. We also provide Wholesale Steel Cut Wire Shots at the most prolific deals. Technical & Physical Specifications Cut wire shots are manufactured as per IS 5873/1970. Manufactured using of spring steel wire with Carbon contents : 0.4% to 0.85% Uniform hardness : 400 To 500 HV Grade II as per IS 4454 Available In Cut Form: Due to its sharp edge, it is ideal for cleaning where speed of cleaning is critical and somewhat rough finish is acceptable. Conditioned Form: Rounded off through a conditioning process. It is generally used in shot peening process and in industries such as aerospace, shipping, automotive. Cut wire shots are used for cleaning, deburring, descaling, shot peening on components of iron and steel. Depending upon the applications, various hardness ranges are available. Advantages of Cut Wire Shots Lower surface contamination Do not break, hence no dust Reduce the cost of break down and maintenance Reduce the processing time in peening/blasting Give Smooth and bright finish Double the life as compared to steel shots approximately Available in equal hardness and sizes Whole bodied shot with no scales or oxides present

steel abrasive

Get Price Quote

Steel abrasive of Watch CaseBand,Glass frame accessories, Camera Parts, Stainless Steel Pipes, S.S. Cutlery, Brass decorative articles and Wooden Products.

Steel Shots

Get Price Quote

Features : Long Shelf life, Precisely Processed, High Purity. We offer our clients with a comprehensive range of Steel Shots. These are procured from reputed manufacturers and checked on various quality parameters. Our range is in accordance with the prevailing international quality standards and offered at competitive prices.

cast steel shots

Get Price Quote

These Cast Steel Shots are manufactured to last long. We are instrumental in offering the products in premium packaging material that is certified by the experts, followed by stern packaging of the products by the .professionals. Superior transportation facilities, efficient workforce and on-time delivery of the products make us stand out from the crowd.

Peening Steel Shots

Get Price Quote

1 Ton (MOQ)

Mild Steel Shot

Get Price Quote

Stainless Steel Cut Wire Shot

Get Price Quote

Stainless Steel Shot

200 Per Kilogram

We make sure that the products we offer to our clients will remain free from any kind of damage. Thus, we store the entire lot under secured environment in our capacious warehouse. We make use of premium material for packaging the offered lot so as to ensure safe side deliveries.

Steel Shots

Get Price Quote

Steel Shots that we offer are spherical grains made of molten steel through an atomization (granulation) process. These cast Steel Shots are available in different sizes & hardness, which suits the requirements of the clients. Steel Shots, offered by us, are manufactured from steel scrap that is melted in an electric furnace, which are then being atomized into shots by water jet.

Steel Shots

76 - 83 Per kg

500 K (MOQ)

We are Traders of Foundry Raw materials and consumables based at Coimbatore and branch office in Chennai. We deal with Steel Shots , Refracrory lining /Silica ramming mass for Induction Furnace Lining ,Grinding wheels (CUTWELL Brand) and othe materials depending upion customer requirements. We supply Steel Shots of Grade SS550 & SS660 to many foundries in South India