Thermo XL foams

One of the best Insulating materials, Thermo XL – is chemically crossed linked polyethylene is Closed Cell structure. It is produced in continuous rolls resulting in a foam product with uniform, Close cells and smooth skins on both sides. It is light weight, flexible and soft to touch, yet strong, tough, resilient and resistant to moisture, many chemicals and temperature extremes.Thermo XL foams are extensively used as insulation and sound absorbing materials in a host of container’s designs.It is easy to work in fabricating and thermoforming. Thermo XL foams are right at home in the building and construction industry where thermal insulation, moisture resistance, sound and vibration are critical. Indoor or outdoor Thermo XL foams build success.Thermo XL foams also used in backpack padding, luggage and similar application are benefiting from a wide array of beautiful colors and variable densities. FEATURES More than 90% closed cell – negligible water/moisture absorption -wide Operation range -40 ‘ c to + 115’ c Weather resistant & Shock proof because of tri dimensional cross linking of cell Provides heat and sound insulation of the area it is applied Has high resistance against water and moisture Resistant to growth of fungi & vermin Low and stable ‘K’ value , excellent thermal insulation properties across life span. Non – fibrous , non – toxic and non-carcinogenic Oppose high resistance against impact. Chemically inert Easy to installation It is light weight, elastic and durable. It is hardwearing, it is antibacterial and hygienic It is environmentally friendly, does not contain CFC & HFCF PRODUCT RANGE: THERMO XL PLAINE THERMO XL PLUSE THERMO XL PREMIUM Are also available in one side or both side self adhesive release paper AREA OF APPLICATION HVAC- Duct Insulation Under Deck Insulation Pipe Insulation Acoustic Flooring Construction Automotive Industries IDEAL FOR INDUSRIES Industrial, Factory and Poultry sheds Shopping malls and Multiplexes Airports, Hospitals, Medical and Diagnostic centers IT, BPOs and other Commercial buildings Pharmaceuticals and Textile mills Data centers, Server rooms, computerized control rooms etc. Manufacturing units, Networking stations and many more. Material is available in different thickness, 6 mm, 9 mm and 13 mm. and the results of the physical properties may vary based on the thickness. Material is available with three different types of Lamination type, Metalized Foil, Aluminum Foil and UV Barrie, and the results of the physical properties may vary based on the thickness. Disclaimer – “The information provided in the above data table is best of our knowledge. The values of the physical properties are basically the average values and are believed to be correct to the best of our knowledge; however it would be buyer’s responsibility to verify should there be a verification needed and determination of suitability of application. MARS POLY FOAM does not take any responsibility of results nor assumes the liability in connection with this advice.”

...more

THERMO TAPE

Effective joint sealing tapes to prevent heat loss and guard against condensation.High performance , fire retardant , non – fibrous tri dimensional cross linked PE foam tape for perfect joint sealing application , specially available in one side self adhesive coated , one side metalized foil other side self adhesive coated , one side Aluminum foil other side self adhesive coated , and both side self adhesive coated available in various width and length with acrylic adhesive for excellent adhesive over various substrates. FEATURES High bonding strength for various insulation foam surface Flexible yet strong adhesive at joint even an angularsurface . Hence suitable for face to face joint , corner joint , under deck insulation over lap area of roofing joint , pipe joint , Duct joints sealing Tape with stiff release paper for easy to install PRODUCT RANGE Available in 25mm , 50mm , 75mm , 100mm width Thermo pe plain tape with one side and both side self adhesive release paper Thermo pe plus tape with one side self adhesive release paper Thermo pe premium tape with one side self adhesive release paper Thermo XL plain tape with one side and both side self adhesive release paper Thermo XL plus tape with one side self adhesive release paper Thermo XL premium with one side self adhesive release paper

...more

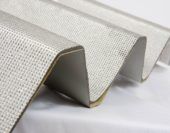

Thermo PE Insulation Roll

PRODUCT DESCRIPTION Thermo PE known as highly competent and most economical solution for Insulation, is non-cross linked, expanded polyethylene or Thermo PE of Closed Cell Structure. It is non-cross linked product expanded from low-density polyethylene resins using eco friendly butane as a blowing agent. It uses the State of the Art technology of heat lamination to develop the thickness of the Thermo PE Foams that varies in the range of 6-100 mm as well as to form a laminate and composite multi-layered structure of homogenous bonding. In comparison with non-cross linked Polyethylene Foam, which generally provides superior thermal stability and insulating properties. TPEermo PE is widely used for Thermal Insulation as one of best Low Cost Option as Thermo PE has heat and fire prevention, heat and sound insulation and prevents friction. Thermo PE is also known for its corrosion resistance, which is due to the use of a series of superior characteristics. FEATURES Closed cell – negligible water/moisture absorption It is Light Weight, non-dusting, Non – fibrous, hardwearing durable material Provides heat and sound insulation of the area it is applied Weather resistant & Shock proof because of multi-dimensional cross linking of cell withstands wide range of Temperature from -40 °C to 80 °C Easy to install Its non-toxic and Odorless and has high resistance against water and moisture Resistant to growth of fungi &Chemicals Low and stable ‘K’ value High Impact Resistance & Oppose high resistance against impact Has good Flexibility and Elasticity Chemically Inert It is environmentally friendly, does not contain CFC & HFCF PRODUCT RANGE THERMO PE PLAINE THERMO PE PLUS THERMO PE PREMIUM All are also available in one side or both side self adhesive release paper Available in AREA OF APPLICATION Under Deck Insulation Pipe Insulation Acoustic Flooring Construction Automotive Industries Construction Packaging material for various purposes Manufacturing of Sports & Recreation items IDEAL FOR INDUSRIES Industrial, Factory and Poultry sheds Shopping malls and Multiplexes Airports, Hospitals, Medical and Diagnostic centers IT, BPOs and other Commercial buildings Pharmaceuticals and Textile mills Automotive Furniture Manufacturing units, Networking stations and many more. Material is available in different thickness, 1 mm to 10 mm one layer, up to 10 mm have multi layer. and the results of the physical properties may vary based on the thickness. Material is available with three different types of Lamination type, Metalized Foil, Aluminum Foil , UV Barrie , one side self adhesive and both side self adhesive with released paper , and the results of the physical properties may vary based on the thickness. Disclaimer – “The information provided in the above data table is best of our knowledge. The values of the physical properties are basically the average values and are believed to be correct to the best of our knowledge; however it would be buyer’s responsibility to verify should there be a verification needed and determination of suitability of application. MARS POLY FOAM does not take any responsibility of results nor assumes the liability in connection with this advice.”

...more

THERMO BUBBLE FILM

Thermo Bubble Film , is a flexible Insulating, packaging and cushioning material made of polymeric film comprising of small air pockets. The symmetrical Thermo bubble pattern ensures excellent cushioning & provides protection against transit damage whereas the Reflective bubble insulation made of polyethylene Thermo bubble film laminated with MPET film &also laminated with Aluminum Foil, lamination is available on one side or both side.It is a low reflective material with a low mass to air ratio, which effectively blocks the radiant heat transfer . The bright surface of aluminum Foil and MPET Foil , which are also reflective the lights , Encases the FR Polyethylene air bubble material , Reflects 96% to 99% infra – red radiation received by the surface of the heated slated roof. The placement of the radiant barrier shall be in a manner to provide an air space below the roofing sheets or between vertical cladding for its effective utilization. FEATURES High reflective value – reflects 96% to 99% of radiant heat Unaffected by alkalis , alcohols , detergents , petrochemical products and most mild acids Nontoxic and fiber free – Environment & User friendly Negligible water transmission Corrosion resistant Excellent tensile strength , Puncture and tear resistance Non carcinogenic chemically inert and does not any formaldehyde or other combustible volatile Organic Compounds. AREA OF APPLICATION Under Deck Insulation Automotive Industries Packaging material for various purposes IDEAL FOR INDUSRIES Industrial, Factory and Poultry sheds Shopping malls and Multiplexes Airports, Hospitals, Medical and Diagnostic centers IT, BPOs and other Commercial buildings Pharmaceuticals and Textile mills Disclaimer – “The information provided in the above data table is best of our knowledge. The values of the physical properties are basically the average values and are believed to be correct to the best of our knowledge; however it would be buyer’s responsibility to verify should there be a verification needed and determination of suitability of application. MARS POLY FOAM does not take any responsibility of results nor assumes the liability in connection with this advice.”

...moreBe first to Rate

Rate ThisOpening Hours