Taper Shank Type Thermowell

Our highly durable Taper Shank Type Thermowell is manufactured from the premium raw materials. Adhering to strict quality norms, we design Taper Shank Type Thermowell as per the national and international quality standards. To meet the different requirements of the clients, we offer Taper Shank Type Thermowell in varied dimensions.

...more

Straight Shank Type Thermowell

Designed as per the national and international quality standards, our Straight Shank Type Thermowell provides excellent performance. Available in different specifications, our Straight Shank Type Thermowell is sure to meet the expectations of the clients.

...more

Orifice Plate (SEWNFL)

SEWNFL is used for high to very high pressure steam lines and Hazardous fluids where leakage can not be tolerated.

...more

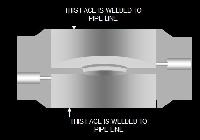

Orifice Plate (SEWN)

SEWN is for general purpose use and is welded between pipe line. Used for high pressure lines

...more

Orifice Plate (SEOP)

SEOP is for general purpose use and is inserted between pipe flanges. Used where line pressure is low

...more

Orifice Plate (SECR)

SECR is for general purpose use and is sandwiched between pipe flanges. Used for medium line pressures

...more

Flange Type Thermowell

We provide a wide range of precisely designed Flange Type Thermowell that is in huge demand in the markets. Use of optimum quality raw materials in the production assures the high durability and performance Specifications : Model No.Figure No.ABCD1D2TT1L1SE-3003321/2BSPT20196.6±0.0025950SE-3013321/2BSPT20229±0.0025950

...more

Balancing Pots

We are counted as one of the prime High Pressure Balancing Pots Manufacturers in Gujarat. We offer Balancing Pots that are used for installation of Orifice Flow Transmitters. We manufacture balancing pots using mild steel and stainless steel using latest technological procedures. Known for their effective performance, our balancing pots are highly demanded by our esteemed customers. The Orifice Flow Balancing Pots, offered by us, are used in various industrial applications. Additionally, we design various types of balancing pots depending on the type of applications. We also design single piece design for high pressure applications that is available at highly affordable prices. Features : High DurabilityTensile StrengthRobust StructureResistance to CorrosionLow Maintenance Cost

...more

Bagging Weigher

To meet the demand of industries for high speed bagging of bulk material, SAAS have developed the new “BLG” series of Bagging Weighers. These low cost automatic weighing machines have been designed to handle a wide variety of products with exceptional accuracy at high speed. Depending upon the characteristics of the material to be weighed and required output/hour the selection of the feeding system is done. The weigh Bin is suspended from precision, low creep, low drift load cells. The “BLG” Electronic Bagging Weigher can be combined with almost every type of bag closing and sealing equipment. The accuracy of the machine meets the requirement of weight and Measures authority. We are reckoned as one of the eminent Auto Bagging Weigher Manufacturers & Exporters from India. Packing of Materials like : Soda AshMilk PowderCokeSugarOther Powdery & Granular Materials Standard Features : Control unit with built in Digital weight indicatorPush button TarePreset counterFast 12 bit A to D converterAdjustable Set Point for coarse feedAdjustable Set point for fine feedAutomatic Tare control After predefined bag countsEmergency StopEssential parts are of stainless steel Optional (Feeding System) : Shutter dosing (SD)Single screw dosing (SSD)Double screw dosing (DSD)Chute dosing (CD)Belt dosing (BD) Design Feature : Robust construction suitable for most difficult operating conditions.Weighing hopper with bottom dischargeRobust electro pneumatic control systemAnti vibration design of weigh bin Technical Data : Maximum Load : 100KgOperating voltage : 220 v. 50HZType of Enclosure : IP 54Service Air Pressure : 7 BarAir Consumption : 6 N l/bagPipe Connection : ½ inchAccuracy : As per requirement of W&M * * More Details on Request.

...more

Air Pressure Regulator

Air Pressure Regulators are ideally designed for precise controlling of the air pressure on the downstream side of the regulator. All pneumatic instruments require pressure regulators to supply them air at constant pressure. Our Adjustable Air Pressure Regulators have a proven track record in various industries for their performance and appreciated for their small size, high air volume and low cost. Universal Mounting is an added quality of your regulators. Our standard material of construction is mentioned below but we can make regulators in any material composition as per customer�s requirement. Moreover, our company is counted as one amidst the prominent Compressor Air Pressure Regulator Manufacturers, based in India. Details of Regulator : Components : The assembly has three main sections. A bonnet which houses the adjusting stem and loading spring. The locking nut is provided on the loading stem and prevents accidental change of the regulator knob setting.A centre ring containing the pilot stem and the supply and exhaust port.An end cap which holds the cleaning plug for removing dirt and sediments. Materials : Durable corrosion resistance materials are used throughout this device. The bonnet is cast Aluminum, the loading spring is cadmium plated, the pilot stem is bright bar special quality and has a Teflon valve seat. The diaphragm is a neoprene coated fiber glass material for maximum resistance to stretching which ensures minimum drift. Adjustments : Clockwise turning of the adjusting screw increases the pressure. To reduce the pressure, turn the adjusting screw anticlockwise. Maintenance : With clean air supply the regulator will give long uninterrupted service. Faulty air regulator working or loss of regulation is usually due to dirt in the disk area. Cleaning of this area will ensure good working again.For cleaning remove bottom plug and spring and clean disk with denatured alcohol. Wipe off seat and blow out body with compressed air. Re-assemble the parts of the unit and put regulator in operation. Description of Parts : Setting KnobLock NutLoading SteamBonnet With Mount HolderLoading SpringExhaust PortDiaphragmPilot StemRegulated Outlet PortOutlet Entry ¼ Inch BSP FemalePlugInlet Entry ¼ Inch BSP FemalePilot Spring Mounting : The unit is suitable for pipe in line and flush mounting. Specification of Air Pressure : Maximum Inlet Pressure : 150 PSIReduced Output Pressure : 0 to 40 PSIUse : With all pneumatic instrumentsModel Number : SEPR-01

...more

Automatic Packaging Machine

Bagging Machine

orifice assembly

Orifice Plates

Semi Automatic Packaging Machine

Orifice Plate Calculation

We are counted as one of the most prominent provider of Orifice Plate Flow Meter Calculation Services in India. We conduct Orifice Plate Calculation that is appreciated for their accuracy. Our Orifice Plate Flow Calculation Services are available at highly competitive prices. We calculate orifice plates for : Commercial application (approximate flow)Industrial application (accurate flow)Scientific application (highly accurate flow) All factors affecting Orifice Plate Flow Meter Calculation are taken into consideration while designing the orifice plate to ensure highest possible accuracy. Some of these factors are mentioned below : Fluid type, tap location or element type, meter type, orifice plate, vent or drain holePipe size, maximum flow, normal flow, temperature, pressure, specific gravity, super compressibility factor, water vapor, density, viscosity, differential, permanent loss, ratio,F specific heats, Reynolds no of pipe at normal flow, gas expansion factor, flow coefficient, Reynolds number correction, discharge coefficient, upstream tap location, downstream tap location, coefficient and beta ratio.

...more

Installation & Commissioning

We are actively involved in providing world-class Orifice Installation services. Features : Accuracy in CalculationsGuaranteed Orifice DimensionsDevelops a Mechanical, Electrical or Hydraulic Force for the purpose of Measuring FlowEffective and AffordableOrifice is a device usually in the form of a restriction, inserted in the pipe line to develop a mechanical, electrical or hydraulic force for the purpose of measuring flow. There are many factors which should be considered when selecting a primary device. Most of these factors are not inter-related. Due to this reason a compromise is generally the rule for selection of Primary devices. Only experienced engineers can decide and design primary elements to have the best compromise. We have more than 40 years of experience in calculation, designing manufacturing, Erection and Commissioning of primary flow devices like Orifice Plates, Orifice Assemblies and Flangeless inline Orifice assemblies for High pressure systems. We also under take the job of rechecking of calculations of your existing Orifice Plates. We also suggest the best location of Flow Device Installation in pipe lines for minimum flow errors. Last but not the least the Orifice Installation & Commissioning Services, offered by us, are available at pocket-friendly prices.

...more

computer hardware services

computer software services

Erection Services

flow measurement services

overhauling services

pressure measurement services

Be first to Rate

Rate ThisOpening Hours