Rubber Conveyor Belt

600 Per Piece

10 Piece (MOQ)

Title: Receive High-End Rubber Conveyor Belts With Dayal Marketing Services When it comes to the matter of selecting the best types of conveyor belts that can efficiently move industrial products from one place to another the ideal option is rubber conveyor belts. Are you also in search of a well-known rubber conveyor belt manufacturer which can deliver the best quality rubber conveyor belts for transporting loads in industrial possessions? If yes then no ther brand can offer better products than Dayal Marketing Services. Being one of the well-reputed rubber conveyor belt manufacturers in India, we offer high-end rubber conveyor belts that are made with the best quality rubber which makes them capable of carrying a load of 15-20 kgs. Since we are the best rubber conveyor belt manufacturers in Thane India, all our rubber conveyor belts are made with high-quality rubber, they are used for moving industrial goods in massive industrial possession. All our rubber conveyor belts are available in black colour with plastic belting and chains. The rubber conveyor belts we manufacture are highly durable, reliable and known for strong and sturdy construction and non-stop operation. Since we are a renowned rubber conveyor belt supplier in India, the rubber conveyor belts we make are available anywhere in India with top-level packaging and obstacle-free delivery procedures. The price of each rubber conveyor belt is 600 rupees and the minimum order quantity is 10 pieces or meters. Hence Contact Dayal Marketing Services to order the best rubber conveyor from the well-known rubber conveyor belt manufacturers in Thane.

Rubber Chevron Conveyor Belt

1,200 - 3,800 Per Meter

500 Meter (MOQ)

APPLICATION Patterned conveyor belt is an inclination conveyor belt composed of Patterned work surface, flat non working surface and core. It is suitable for conveying powder, granular, small pieces materials with the inclination of 0 ~ 40 ° to prevent the material from falling. We often apply it in: conveying bulk material in stone crushing plant, waste recycling plant, sand and gravel aggregate manufacturing plant, thermal power station, concrete mixer plant, mine mining plant, metallurgy plant, port / terminals/ dockside, etc FEATURES 1. There is no joint in belt carcass 2. Long service life 3. Cleats and top cover rubber are vulcanized integrally 3. Cleat pattern, angle and pitch are designed elaborately 4. There are open type and closed type, suitable for bulk or bagged materials such as powder and granule with incline less than 45°. Type Cleat Size (mm) Belt Width (mm) CV, full width Cleat Height=5; 10 Cleat Width= full width Cleat Pitch=100 300-1200 CV, closed Cleat Height=15 Cleat Width=300; 450 Cleat Pitch=250; 300 400-1200 CV, open Cleat Height=15 Cleat Width=385; 600; 750 Cleat Pitch=250 450-1200 CP, open Cleat Height=17 Cleat Width=300; 440; 550; 630; 750; 950 Cleat Pitch=330 400-1400 CP, open & closed Cleat Height=25 Cleat Width=450; 550; 750 Cleat Pitch=330 500-1200 CP, open Cleat Height=32 Cleat Width=580; 630; 750 Cleat Pitch=330 700-1400 U, closed Cleat Height=15; 32 Cleat Width=550; 700 Cleat Pitch=350; 400 650-1200 Multi-V, full width Cleat Height=6 Cleat Width= full belt width Cleat Pitch= 76 500-2000

Best Deals from Rubber Conveyor Belts

Rubber Conveyor Belt

800 - 1,500 Per Meter

200 Meter (MOQ)

Rubber Conveyor Belt

Get Price Quote

We are a well-reckoned Rubber Conveyor Belt Manufacturer, Exporter and Supplier from Delhi. Rubber Conveyor Belt, which we offer, is made from the best quality raw materials that are procured from the leading vendors of the domain. The Precision Rubber Conveyor Belts is widely demanded for various industrial applications. Avail Rubber Conveyor Belt from us at the leading market prices. Attributes Durable Robust Precision made Cost effective

Black Heat Resistant Rubber Conveyor Belt

720 - 2,400 Per Meter

50 Meter (MOQ)

Rubber Chevron Conveyor Belt

100 - 1,550 Per Pieces

2 Piece(s) (MOQ)

Food Grade Rubber Conveyor Belt

Get Price Quote

Chevron Rubber Conveyor Belt

Get Price Quote

Far-famed for the outstanding range of Chevron Rubber Conveyor Belt; we are a leading name in this trade. With the assistance of our secured payment procedures, our clients prefer us all the more. Our transactions support online as well as offline modes.

Rubber Conveyor Belt

Get Price Quote

Rubber Conveyor Belt

Get Price Quote

We make Conveyor Rubber belts from 400mm until 1600mm widths in plies ranging from 3 to 10. Our belts are also exported world-wide in Covers quality ranging from N17 , M24, OR , SHR etc. We also make Rough Top belts as well as Wavy top belts for packaging industry

Rubber Conveyor Belts

800 - 1,800 Per Meter

50 Meter (MOQ)

Sandhya Enterprises supplier of Rubber Conveyor Belts. size: 1.6mm Thickness 2Ply to 3ply 2.8.0mm Thickness 2ply to 3ply 3.10.mm Thickness 3 to 4ply 4.12.0mm Thickness 3 to 4ply Width 100mm to 1500mm. Use for RMC Plant , Cement Plant and Crusher Plant.Conveyor belts are mechanical devices used to transport materials or objects from one point to another in a continuous manner. They are widely used in various industries, including manufacturing, mining, agriculture, logistics, and more. Conveyor belts consist of a continuous loop of flexible material that is driven by pulleys or rollers, allowing for efficient movement of goods or materials. Here are some key features and components of conveyor belts: 1. Belt material: Conveyor belts are typically made from various materials depending on the specific application requirements. Common belt materials include rubber, PVC (polyvinyl chloride), polyester, nylon, metal, or a combination of these materials. The choice of material depends on factors such as the type of material being conveyed, its weight, abrasion resistance, temperature resistance, and environmental conditions. 2. Belt structure: Conveyor belts are constructed with layers of material that provide strength, flexibility, and durability. The most common belt structure consists of a carcass, which is the core layer that provides tensile strength, and one or more cover layers that protect the carcass from wear, abrasion, and external elements. 3. Drive system: Conveyor belts are driven by a motorized pulley, drum, or a set of rollers. The drive system applies power to the belt, causing it to move. The drive can be located at either end of the conveyor or at intermediate points, depending on the length and configuration of the conveyor system. 4. Rollers and idlers: Conveyor belts run on rollers or idlers, which support and guide the belt along the conveyor path. These rollers can be made of steel, rubber, or other materials, and are designed to minimize friction and facilitate smooth movement of the belt. 5. Belt tracking system: To ensure proper alignment and tracking of the belt, conveyor systems may include a tracking mechanism. This can be in the form of adjustable idlers or automated systems that help keep the belt centered and aligned on the conveyor. 6. Accessories: Various accessories can be added to conveyor belts to enhance their functionality and safety. These may include belt cleaners to remove debris and material buildup, belt fasteners for joining belt ends, skirt boards to contain material on the belt, and safety devices such as emergency stop switches and belt misalignment sensors. 7. Specialized belts: There are specialized conveyor belts designed for specific applications, such as heat-resistant belts for high-temperature environments, food-grade belts for the food industry, oil-resistant belts for the mining industry, and more. These belts are formulated with specific materials and features to meet the unique requirements of their respective industries. Proper maintenance and regular inspection of conveyor belts are crucial to ensure their efficient and safe operation. This includes monitoring belt tension, checking for wear or damage, and performing routine cleaning and lubrication. When selecting a conveyor belt, it is important to consider factors such as the type and weight of the material being conveyed, the operating conditions (including temperature, humidity, and presence of chemicals), the required speed and capacity, and any specific industry regulations or standards. Consulting with experienced conveyor belt suppliers or manufacturers can help in choosing the appropriate belt type and configuration for your specific application needs.

Rubber Conveyor Belt

Get Price Quote

50 Meter (MOQ)

Rubber Conveyor Belt

Get Price Quote

1 Nos (MOQ)

Rubber Conveyor Belts

Get Price Quote

We provide General Purpose Conveyor Belts that are manufactured in accordance to the international quality standards. The General Purpose Conveyor Belts that we present have no alternative available in the market when it comes to high reliability and cost effectiveness. Also, we are one of the distinguished General Purpose Conveyor Belts Manufacturers, exporters, and Suppliers in India. These belts are mainly produced with Rubber cover M-24 and N-17. However we produced General purpose conveyor belts with following rubber cover and properties. Besides this if any customer request his own cover properties the same can also be produced and supplied by us. Applications of General Purpose Conveyor Belts : Crushers, Mining, Coalliers, Thermal Plants, Cement Plants, Steel Plants, Fertilizer plants, Ports, Minerals and Metal Industries etc.

Rubber Conveyor Belt

650 - 3,500 Per Meter

5 meter (MOQ)

Rubber Conveyor Belt

1,000 - 1,500 Per Meter

100 Meter (MOQ)

Features Diverse Applications: Our conveyor belts are suitable for a wide range of industries, including manufacturing, mining, agriculture, logistics, and more, where efficient material handling is essential. Custom Solutions: We offer various belt types, sizes, and configurations to match the specific requirements of your conveying systems, ensuring optimal performance. Premium Materials: Our belts are crafted from top-quality materials, chosen for their durability, wear resistance, and suitability for various environments. Reliable Operation: Our conveyor belts provide smooth and reliable material transport, minimizing downtime and optimizing productivity. Easy Installation: Installing our conveyor belts is straightforward, reducing setup time and maintenance costs. Industries We Serve Our conveyor belt products are trusted in diverse industries where efficient material handling and transport are critical. Whether you're in manufacturing, mining, agriculture, or logistics, we have the right conveyor belt solution for you. Quality Assurance Quality is at the core of our manufacturing process. Our conveyor belts undergo rigorous quality control measures to ensure they meet industry standards and your expectations. When you choose our products, you choose reliability. Why Choose Us Expertise: With years of experience, we have perfected the art of conveyor belt manufacturing. Innovation: We stay at the forefront of technology to provide cutting-edge solutions. Customer-Centric: Your satisfaction is our priority. We work closely with you to understand your conveying needs and provide customized solutions. Global Reach: We serve customers worldwide, delivering top-quality conveyor belts wherever you need them.

Rubber Conveyor Belt

Get Price Quote

Rubber Conveyor Belts

Get Price Quote

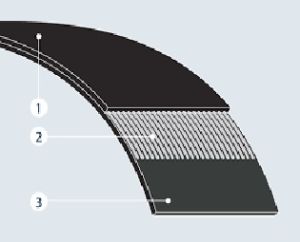

Conveyor belts generally consist of cover rubber, carcass and rubber skim coat. The reinforced breaker fabric is used for extra protection.COVER RUBBER :Covers of natural or synthetic rubber are designed to protect the carcass from -abrasion, impact, deterioration and other injurious influences. They are compounded to meet particular service conditions such as abrasion, oil, heat, fire, chemical resistant and antistatic, etc. CARCASS :Carcass of a belt maintains the belt tension and supplies structural strength; it does all of the work in supporting and pulling the load. Carcass consists of multiple plies of rubber impregnated fabric bonded with friction and skim coats. The fabrics most commonly used are; nylon, polyester and cotton.RUBBER SKIM COAT :Â An extra layer compound between plies that increases flex life and creates a more elastic link so that plies flex without separation. Skim coats cushion fabrics against impact and help protect against moisture. BREAKER FABRIC :A specially woven fabric between the cover and the carcass to improve adhesion and provide better resistance to cover stripping, gouging or tearing. This is normally used in belts handling primarily crushed and sized material which gives great impact to the belt when lumps drop at a loading point. COMPOUND AND USAGE :The cover rubber determines belt life and the selection of the correct cover rubber grade and thickness is most important.HEAT RESISTANT CONVEYOR BELT :In general, it is economical to adopt a heat resistant belt if the temperature of the material to be carried is over 60 C (140 F). As the damage of cover depends on the temperature and nature of transported material, the proper selection of a belt to fit particular operating conditions is important. Especially the relation of temperature between the material and belt surface should be considered when selecting the belt.When transporting material of high temperature of belt surface rises by contact with the material, but on the return journey the heated surface gets cooled naturally by air so that the surface temperature becomes considerably cooler than that of the material. The temperature depends on kind, size, temperature quantity of material to be carried, belt speed, belt length and etc. This belt is designed for transporting cement clinker, cokes, sintered ores, soda ash, chemicals, fertilizer and etc.ABRASION RESISTANT CONVEYOR BELT :Material being carried as well as idlers and frame of the conveyor may cause excessive wearing on normal belts. To prolong the life of the belts running under severe wearing conditions, special and super abrasion rubber is compounded for the belt covers.OIL RESISTANT CONVEYOR BELT :Oily material causes the ordinary rubber covers of the belt to swell and peel off, which results in a complete breakdown in the conveyor system. This belt compounded of oil-resistant -quality synthetic rubber has good resistance to the damaging effects encountered when conveying oil or oily materials. FIRE RESISTANT CONVEYOR BELT :This belt is a prerequisite to prevent fire risks in coal mines where not easily accessible and to reduce maintenance of the conveyors which may be damaged by flame at the blast furnaces of iron works. ANTI-STATIC CONVEYOR BELT :This belt is made especially for use where, for instance in the paper or textile mills, the products being carried stick to the belt surface, or fire risks may be involved due to electro-static sparks.

Polyester Reinforced Rubber Flat Belts

2,000 - 10,000 Per piece

1 Piece (MOQ)

VSI ENTERPRISES is one of the leading Manufacturers and suppliers of flat belts, Power Transmition flat belts are manufactured with Rubber - Polyester Fabric and Rubber, which is more flexible and 25 % higher Strength as compare to classical Nylon sand with flat belts. For this type Low tensioning arrangement required because of high strength of load carrying member. Our flat belts are work flawlessly during their life span. Power Transmition flat belts Construction: 1) Top Cover for covering or Friction ( Rubber) 2) Core Member is for load carrying ( High Strength Polyester) 3) Bottom cover is for Friction ( Rubber) Belt Types : GG : both side rubber coating We are also manufacturing and supplying truly endless flat belt for very high RPM and temperature. Application Area: Textile industries, Pulp & paper industries, Iron & steel industries, Machine tools Automotive Stamping Industries, Paper & printing industries

Rubber Conveyor Belts

Get Price Quote

We are listed at the apex as a Rubber Conveyor Belts Supplier in India. We provide all types of Rubber Conveyor Belts for shot blasting machines and for other type of conveyor systems in various grades such as Food Grade, Heat Resistant, etc. The unmatched quality and unsurpassable performance attract various industrial sectors to place repeated orders for the Rubber Conveyor Belts from time to time. Additionally, customers are eased with the availability of the Industrial Rubber Conveyor Belts in varied sizes and dimensions. Sizes Available For Tumblast Shot Blasting 20x 27 machine 27X 36 machine 36X 42 machine As per the customers specification Type Available Airport (Baggage handling conveyors) Pharmaceutical (Medicines) Fruit Pulp processing (Food grade conveyors) etc. Salient Features Resistant to adverse conditions like heat and fire High strength Wear resistant grade Great performance Cost effective