Cyclone Dust Collector

Get Price Quote

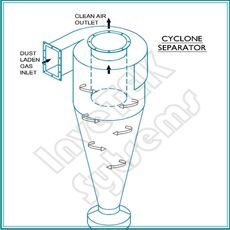

Single cyclone, Multi cyclone dust collector You can rely on us for all your customized requirements of cyclone Separators "Plutontek supplies Cyclone Dust collectors, in variants such as Single Cyclone as well as Multy Cyclone. Plutontek Cyclone duct collectors / Separators are the most efficient and cost-effective solution available for your pollution controlling requirements. Plutontek Cyclones are offered in capacities from 800 CFM to 40,000 CFM and can efficiently remove moderate to large sized particles from the air stream. The centrifugal action of the Cyclone, created by rapid rotation of the high velocity air stream, forcibly precipitates the dust out through the bottom of the Cyclone and into a collection hopper. All models can be housed indoors or outdoors" "We have different type of models for variety of applications to handle fine dust, explosive dust, high temperature dust, adhesive dust etc. in all industrial sectors. Finding the application usage in cement Plant, Steel Plant, Food Industries, Heat treatment plant, Pulp and Paper industries, Chemical plant , Foundries, pharmaceutical industries etc. With increasing gas volumes it is difficult to attain the desired dust collection efficiency in a single cyclone construction. Hence our range includes multi-cyclones with custom made sizes. We offer multi cyclone dust collectors like twin cyclone dust collectors, quad cyclone dust collectors & double quad cyclone dust collectors. Multi Cyclone dust collectors are also called as cyclone dust separators due to its ability to settle the bigger dust particles & allowing the lighter & smaller dust particles to get collected in bag houses or dust filters. Mostly light duty cyclones are used for collection of non-abrasive, granular or fibrous dusts and shaving compared to Heavy duty cyclones which are used for collecting chips or other materials in pieces." Uses in Boilers Multicyclone Dust collection systems manufacturing efficiency ranges from 94% to 97% to suit Boilers of 5TPH To 55TPH Coal, Husk & Baggase Fire Boilers. Multi Cyclone dust collectors are mainly used to create a centrifugal force to separate dust from the polluted air stream.

Cyclone Dust Collector System

150,000 Per Piece

01 Piece (MOQ)

Best Deals from Air Pollution Control Equipment

Bag Filter

2 Per Piece

Being a client centric organization, we are able to manufacture and supply Bag Filter to our valued clients. Features: Efficient operations Excellent durability Optimum functionality

Oil Filter

Get Price Quote

Oil Filter. With the help of our state-of-the-art infrastructure unit, we are able to manufacture and supply the superlative quality of Oil Filter. Utilizing the best quality raw material and sophisticated technology, our experienced professionals design this filter in compliance with set industry standards. Highly used in various applications such as air handling and others, offered filter is available in variegated sizes and specifications. Features: Effective filtration Low maintenance Robust construction

Pressure Swing Adsorption System

45,000 Per piece

Pressure swing adsorption or PSA is a process that separates single gases from a gas mixture. PSA is a non-cryogenic air separation process that is commonly used in commercial practice. It is an economic and reliable method for separating many gases and achieving a very high purity level for them.

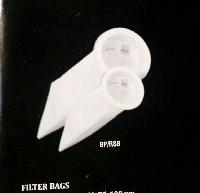

Filter Bags

Get Price Quote

We are a dignified Filter Bags manufacturer, Exporter, and Supplier in the market. Our Bag Filters are manufactured using the finest grade raw materials like mild steel, which makes it durable and corrosion proof. Our Bag Filters are widely used for removing particulate materials from general ventilation air. Attributes : Excellent performance Resistance to corrosion Damage proof Highly durable Affordable prices Used For : Collecting dust Controlling pollution

Cyclones

Get Price Quote

Cyclones disengage entrained dust from a carrying gas stream. Often called cyclone collectors, multi-cyclones, cyclonic separators and cyclonic dust collectors. Cyclone collectors are used for product recovery of dry dusts and powders and as primary collectors on high dust loading air pollution control applications.

Belt Driven Blowers

Get Price Quote

We make smooth and on-time deliveries of the product range that we keep safe in our capacious inventory. Now procure Belt Drive Blower at extremely reasonable prices from us. Our organization is its famous supplier.

Fume Extraction System

Get Price Quote

We are amongst the specialists in manufacturing and exporting Industrial Fume Extraction System. Our products are precision designed and those are as per with the market trends and industry standards. Over the years we have been ensuring that all the raw materials and the spare parts used in the manufacturing process are procured from the most reputed vendors of the domain. The system is designed to capture soldering brazing fumes, dry fumes, welding fumes, buffering and dust.

cartridge dust collectors

Get Price Quote

cartridge dust collectors, fly ash silo

Dust Collectors

30,000 - 250,000 Per unit

1 Set (MOQ)

SS Bag Filter Housing

59,000 - 60,000 Per Piece

Flow Rate 5m3/hr to 50m3/hr

Filter Bag Cage

Get Price Quote

We are involved in offering an extensive range of Stainless Steel Filter Bag Cage. These cages are widely used in the major air pollution control systems. Manufactured using the controlled welding machines, these cages are assured of the topmost quality. Provided with galvanized electroplating, the range of filter bag cages offered by us is highly resistant to corrosion.

Air pollution Control System

Get Price Quote

Now procure Pollution Equipment at extremely reasonable prices from us. Our organization is its famous manufacturer and supplier. Located at Maharashtra(India), we are reckoned for providing excellent array of products throughout the country.

Cyclone Dust Collector

50,000 Per Set

Bag Filter

100,000 Per Piece

Air Pollution Control Equipment

Get Price Quote

For making sure about the safety of the products during handling, transporting and warehousing, we make use of quality packaging material. And, this task is accomplished by our deft professionals. Our team of experts is capable of entertaining the voluminous orders in shortest time possible. Features : Longer life Reliable Damage resistant

Bag Filters

Get Price Quote

We are offering bag filters. Mechcon places a heavy emphasis on a transparent and an easy-to-operate user environment making the control and system monitoring more user friendly. We offer viewing systems that provide maximum comfort for personnel controlling the entire process that are adapted to the requirements of each customer.

polyurethane hydrocyclone

2,000 Per Piece

Lug Brushing Machines With Dust Collector

Get Price Quote

A side view of the machine with brushing arrangement clearly visible. The dust collection is effective & behind the brush mechanism with blower fan on top. Salient Features: No pollution & hence operator friendly Productivity automatically enhanced. Scrap generation collected in tray. Environment protected. Filter media automatically pulsed periodically by use of timers. Equipment is lightweight & hence easily portable Utility Requirements: Brushing motor needs 0.5 H.P. Power Blower motor needs 1.5 H.P. Power Compressed air required at 4 Kg./cm2 for periodic pulsing of filters. Control Panel: Wall mountable design. Operation on wall mounted panel restricted to blower motor start & stop only. Brush motor operation on the grinder for easy start & stop function. Panel input connection is simple with only one three phase incoming supply. Output connection from panel to be given to blower motor & brushing grinder motor & solenoid coil of pulsing valve. FAQ's 1. How important is lug brushing? Is it really necessary? Lung brushing is important and hence necessary prior to group welding in the assembly department since removal of oxide from the lugs exposes the metal surface thereby ensuring a proper welding and bonding of the plates to the busbar. 2. In what way is lug brushing on machine butter compared to filing the plates? Manual filing of plates can result in uneven lug thickness causing lead runs during grouping. Such lead runs if undetected can be the reason for cell shorts and battery failure. Thus it is a quality related issue. Moreover filing of plates manually is laborious, time consuming and hence not economically viable. Further – in addition to productivity the rate of production with manual filing is low and hence unviable considering the competitive nature of today’s business environment. Lastly and not the least – manual filing is polluting whereas the lug brushing machine having the integrated dust collector ensures that the lead dust is collected in a tray resulting in substantial savings for today’s battery manufacturers clean setup. 3. Can the machine be used for industrial plates lug brushing? The machine can be used for positive & negative plates of standard size as well as narrow size automotive plates in addition to using these for all industrial plates. 4. How frequently does the filter media need cleaning? Cleaning of the filter media is done periodically with the help of compressed air. It is for this purpose thatcompressed air forms part of this machine’s utility requirement. A timer in the control panel ensures cleaningof the filter at regular intervals of one minute.

Flowers Mill Dust Collector

21,000 Per Piece

01 Piece (MOQ)

Multi Cyclone Dust Collector

Get Price Quote

The flue gases coming out of the boiler contains dust particle’s embedded in it.The pollution control board of a particular area has limitation on the concentration of dust particles in the gases which are to be release from boiler to the atmosphere.n order to minimize this dust content from the flue gases dust collector system is being used.The main structure due to which the separation takes place is a pipe in pipe construction.The lower side of the outer pipe is tapered downwards.Two duct openings are placed on the flue gas inlet and outlet sides with flanges.

Industrial Filter Bags

Get Price Quote

Micron : 1, 5, 10, 25, 50, 75, 100 umThe BP series bags are made of nonwoven needle felt with glazed finish PP. This finish is created by melting of the outermost surface fibers producing a bond which reduces the possibility fo migration. The PP molded top and the ends are ultrasonically welded together.The RSB series of bags are made of three layers of media. The inner layer works as a pre-filter which is made of coarse Nylon mesh, the center layer is non-woven felt which does the actual filtration and the outermost layer is made with super fine spun bond fabric for final filtration. The unique Rubber collar ensures O bypass & 100% seal and very accurate filtration.Configuration : BP : Dia 4" x 10" & 20" RSB : Dia 7" x 17" & 32" Flow per 10": 100 LPM for 10" BP series and 200 LPM for 17" of RSB for raw water with operating pressure of 2.5 bars.

Bag Filter

Get Price Quote

We are a renowned Bag Filter Manufacturer, Exporter and Supplier in Maharashtra, India. The Bag Filter that we deal in is used in a number of industrial segments across the globe. We utilize quality materials and modern techniques to manufacture Bag Filters. The Bag Filters can be purchased in different sizes from us. What Is Bag Filter Required For? For the resurgence of particulate matter from exhaust gas so thatPollution problems are avoidedPlant yield is increasedFor better Recovery of finished product Note : Recovery of material in powder form is desirable & not in solution form! Apart from Bag Filter, Pollution Control Bag Filter, Cyclones, Scrubbers, Venturi, Electrostatic precipitators, etc. can be used for the recovery or resurgence of particulate matter from exhaust gas. The Dominant Selection Criteria High collection efficiencyFine particulate size Working Principle Of Bag Filter Dust-laden air goes through the bag filterThe dust/powder gets separated inside the chamber of bag air filter.The air is equally distributed avoiding channeling while the powder or dust is being separated.Originally, a layer of material forms on the bags. Consequently, the layer acts as filtering medium.The dust is amassed on filter elements while the air passes through the filter bags from outside to inside.The amassed powder is removed from the bags via reverse pulsejet air erratically.The removed powder falls on base funnel and is discharged all the way through powder discharge valves.The dust free air is then sucked by the draft fan and is finally exhausted to atmosphere.

air pollution control equipments

Get Price Quote

Model :ACSLL20 Capacity :1600 CFM @ 40 MM WG. Rec. Motor :1HP1440RPM Direct Driven (With Crompton Make Motor)

Small Size Filter Bag Cages

Get Price Quote

Ours is a reputed name in manufacturing Small Size Filter Bag Cages. These Filter Bag Cages are specially designed for protection of filter bags and enhancing their working life. Constructed from best grade metals with excellent coating of Teflon or other materials, these filter cages are available in options of top and bottom load designs. These filter cages can be made available in varieties of finishes like epoxy coated, passivation or anti- corrosive painted.Best Features : Longer service life, Corrosion and abrasion resistance, Dimensional accuracy, Exceptional performance.

Hydro Cyclone Filters

Get Price Quote

Parts of dirt with high specific gravity (weight) can be filtered using hydro-cyclone filters. Because of the centrifugal flow of the inlet water the weighed parts are flowed and collected in the bottom container tank.

Dc Blower

6,000 Per Piece

1 Piece (MOQ)

cyclone machine

Get Price Quote

Multiclone Dust Collector

350,000 Per Piece

We are the main supplier of this product.