Multi channel readout for gauging

Get Price Quote

1 Unit (MOQ)

Auto Gauging Machine

Get Price Quote

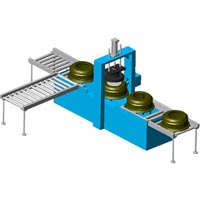

Application : Valve seat OD, Height, Chamfer Gauging & Weighing. Design Element : • Mechanical Indexers • Rodless Cylinder pneumatic slides • Slide Tables • Pallet handling systems • Component Fixtures • Pneumatic Lifters • Aluminum Extrusion frame & guarding etc.

Best Deals from Auto Gauging Machine

Auto Gauging Machine

Get Price Quote

Measuring system for two and four wheeler Crankshafts Measures the crank bore and center distance between crank bore and crank pin If crank bore is within tolerance limit then grouping on center distance dimension and marking on crankshaft diameter of the group is automatic. Air Pressure Sensor provided to control the pressure and safety curtain on the door to avoid any accident at the time of marking the grade. Complete cycle is automatic except loading and unloading the component.

Auto Gauging Machine

Get Price Quote

Non Contact Gauging Technique, Cost effective & fast inspection, Skilled operator is not required, To measure Big End & Small End diameters, Center distance, bend & twist etc

Auto Gauging Machine

Get Price Quote

Our customised multi-gauging solutions range from a simple multi level diameter checking to relational parameters like squareness, center distance etc. to Semi-Automatic to completely automatic inline multi-gauging machines. The process of realizing a customised gauging solution in reality is a complex and elaborate one. It consists of the following steps. Enquiry from the customer: The customer plays a key role of providing the correct and vital information to us which forms the basis of conceptualizing the solution to the customer Conceptualizing: At this stage our concept cell visualizes a solution to gauge the required parameters as per the enquiry Design Approval: Once the concept is frozen, the design team makes an overall layout for the customer to verify whether there is any gap in the inputs at the enquiry stage and what has been put on paper Design: Once the basic design layout is finalized with the customer, based on the concept , the design team gets down to make production drawings of the conceptualized gauging fixture. Constant interaction takes place between the two departments as well as with the customer to clear doubts etc. Manufacturing: Individual parts are carefully produced as per drawings Assembly: An experienced and skilled set of operators assemble the gauging fixture and give shape to the concept In-house Gauge trials and tests: A separate applications team then takes over and conducts extensive trials on the gauging station and ensures the desired results are obtained Customer joint inspection and approval: The output on the gauging fixture is jointly confirmed with the customer at our premises before it is shipped out