battery isolator switch

Get Price Quote

Battery switches isolate the potentially destructive energy in the battery banks when the vehicle is not in use or during emergencies

Scrap Charging Machines

Get Price Quote

SCRAP CHARGERS are suitable for charging the scrap material in to the melting furnaces of SCRAP RECYCLING / ALLOYING units where scrap charging time can be drastically reduced as against manual charging. Charging machine not only reduces manpower required for charging but also makes it a safe operation and reduces possible chances of accidents which may cause because of explosion or metal splash. Since charging time is significantly reduced, door open time is also reduced which straight way results in energy saving as most of the heat contained is normally lost when door is kept open for manual charging which requires more energy to compensate. Distinct benefits of FURNTECK’s SKLENNER / Reverbratory furnaces 1.Melting and Holding is done in single chamber. 2.No blind corners in refractory which allows easy and thorough cleaning of furnace. 3.Metal tapping is possible through PLUG SYSTEM / HYDRAULIC TILTING. 4.Furnace can be optionally equipped with AIR RECUPERATOR. 5.Large full width door access can be provided in order to clean and charge furnace easily

Best Deals from Battery Accessories

powder charging system

100,000 - 500,000 Per No

1 Set (MOQ)

To charge powders from drums/ sacks to silos/ reactors at rates exceeding 2000 kg/hr and over 25 meters. Easy to use. Easy to wash. You can dismantle the whole system in under 3 minutes for washing. No bulky valves/ electrical to be dismantled. All controls are mounted in convenient Starter box. Easy to replace PTFE cartridges for filtration. Optional HMI for multi product setups. CIP/ SIP options possible. High Technology powder conveying in one simple package.

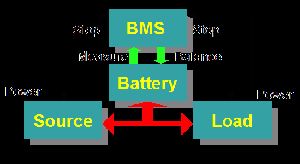

BMS PCM Li-ion

90 - 5,000 Per Piece

1 Piece (MOQ)

We are a trustworthy Supplier, serving the customers with superior quality BMS PCM Li-ion. Only qualitative raw material can result top-notch product range. Thus, we procure it from dependable names in the industry and that too after complete quality confirmation. Customized Lithium Ion Battery Management Systems (BMS) & Protection Circuit Module(PCM).

Battery Terminal Clamps

Get Price Quote

DESCRIPTION Battery terminal clamps provided by us are efficiently used for connecting 12 volts or 24 volts electrical cables with lead-acid battery or battery bank. Our lead battery clamps are corrosion resistance, malleable with low melting points, thus providing excellent conductivity and aptly suitable for battery terminals. We also make battery terminal clamps with nylon because of its high melting point and superior abrasion resistance. NuWay Industries Pvt. Ltd. is well- known for their diverse product line and state-of-the-art manufacturing strategy. From design to product delivery we cater finest battery terminal clamps to your industry. NuWay Industries Pvt. Ltd. is a leading manufacturer of Nylon 6 grade battery terminal clamps. We feel proud in meeting the highest quality specifications, made possible through advanced machinery, on-site engineered and custom-built equipments. Let’s take a look on some of the attractive features of battery terminals which make us different from others Proven robust design Simplified vertical access to fastener Manufactured designs meet international standards Corrosion resistant Simplified serviceability Ability to withstand in different temperature range. Combined with proven reliability, these terminals can be employed in many applications. Take advantage from these lead and nylon battery terminals clamps for safe connection with your battery.

PE Battery Separator

Get Price Quote

The high-tensile strength PE Battery Separator, we supply is manufactured using high-quality materials, like, Rubber, Polyethylene, etc. We have an extensive supply-chain system that empowers us to ensure a distribution of consignments is done within the postulated time. Placed in Pune(India), is capable of catering to local as well as domestic markets without any hassle.

battery saver

Get Price Quote

charging machine

Get Price Quote

Capable of dry charging automotive and industrial battery negative plates, Batch process gives consistent quality plates with over ninety per cent free lead content. Plates have high capacity charge retention, No environmental problems, Compact size with low layout cost, Maintenance and service manual supplied along with the machine.

Battery Protector

600 Per Piece

16) MOTORMAN BATTERY MASK Inhibits sulphonation, Better contact efficiency & longer life of battery. ADVANTAGES : • Provides protective mask to Battery terminals which inhibits corrosion due to battery acid fumes, Sulphonation, attack by moisture and weathering effect. • Improves contact efficiency. • Enhances battery life. METHOD : • Shake can well before use. • Thoroughly clean the battery terminal and spray evenly to thin coat on it. PACK SIZES : • 300gm : suitable for individual customers as well as garages and industry.

Battery Management System

Get Price Quote

battery cut off switch

Get Price Quote

battery cut off switch

Get Price Quote

battery isolator switch

Get Price Quote

10 Piece(s) (MOQ)

This is mainly used in Commercial Vehicles ,Tractors & other construction equipments.

WA Battery Tray

Get Price Quote

PE Battery Separator

Get Price Quote

We have an extensive supply-chain system that empowers us to ensure a distribution of consignments is done within the postulated time. Placed in Pune(India), is capable of catering to local as well as domestic markets without any hassle.

Pvc Battery Caps

Get Price Quote

1000 Piece (MOQ)

Battery Holder

Get Price Quote

Three Phase Steel Battery Cabinet

Get Price Quote

Battery Holder

Get Price Quote

battery cut off switch

Get Price Quote

We ensure our entire range of products is per domestic as well as transnational quality standards, optimum grade and worth the price paid by purchaser. We allow our patrons to make payment through a variety of methods. We are comfortable with patrons making payment through online or offline mediums that are legal and trusted.

Anode Cell

14,000 Per unit

battery clamp

12 Per Piece

Battery Holder

Get Price Quote

Plastic Bottle Separator

Get Price Quote

We are offering plastic bottle separator, varisort c. the varisort c uses an advanced optical sensor capable of differentiating optically different materials precisely and consistently at high speed. It is particularly applicable in the separation of plastic bottles by colour and metals. the varisort c colour separator automatically separates unwanted colour contaminations (e.g. Coloured from clear, non-transparent bottles) from the pet bottle flow.

battery switch

Get Price Quote

Highly puncture-resistant PE separator minimizes the possibility of internal short circuits, Suited for frequent and long power cuts, Faster recharge, less pollution and environment friendly.

powder charging system

Get Price Quote

Powder Charging System is the lean-phased vacuum-conveying mode, which achieves material transfer by introducing the material into the moving stream of air at the desired rate. The PCS uses both vacuum and pressure to move powders and dispenses them with the help of gravity. It can charge powders from drums/ sacks to silos/ reactors at rates exceeding 4000 kg/hr and over 25 meters. . The system ensures the safe transfer of powdered material directly into mixing vessels or reactors, reducing dust generation and wastage as compared to manually charging powdered material through a manhole or a chute. The main purpose of having this contained system is to prevent operator exposure to the sensitive powders which may be hazardous to health and to minimize environmental exposure and cross-contamination to the product. Being operated on a vacuum principle the system is intrinsically dust free. The airflow is promoted by creating negative pressure throughout the system using the vacuum pump.

battery holders

40 - 60 Per Piece

PE Battery Separators

Get Price Quote

.Automobile & Motorcycle Batteries 2.Heavy Duty Batteries 3.High Cold Cranking Amperes 4.Long Life Batteries,Tensile Strength MIN 0.15

Camera Battery Holder

Get Price Quote

We are the main supplier of this product.

battery isolator switch

Get Price Quote

1000 Piece (MOQ)