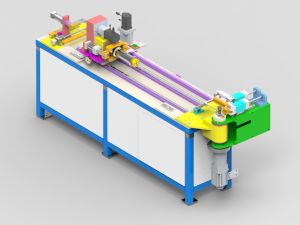

U Bolt Bending Machine

Get Price Quote

1 Piece (MOQ)

A U bolt bending machine is a specialized piece of equipment designed for forming U-shaped bolts from metal rods, commonly used in a variety of applications such as fastening pipes, securing objects to walls, or mounting machinery. U bolts are widely used in industries like construction, automotive, marine, and transportation, making the precision and consistency of these machines essential for high-quality production. Key Components: Bending Dies: These are designed to form the “U” shape by bending the metal rod around a specific radius. The dies are often interchangeable to allow for different bolt sizes. Clamping Mechanism: Holds the rod securely in place while the bending process is carried out. Bending Arm or Rollers: These components push or roll the metal rod into the shape of a “U.” Some machines use a rotary arm to bend the rod, while others use rollers. Control System: An interface that allows the operator to set bending angles, radius, rod length, and other parameters to ensure consistent production. Cutting Mechanism: Many machines come with a cutting system that trims the rods to the desired length either before or after the bending process. Feeding System: Automatically feeds the metal rod into the machine. In automated systems, the rods can be fed continuously for mass production. Working Principle: The straight metal rod is fed into the machine, where it is clamped securely. The bending dies or arms are positioned according to the desired U bolt dimensions. The machine bends the rod around the dies to form the U shape, either by pushing, pulling, or rolling the rod. Once the U shape is formed, the machine may cut the rod to the required length, depending on the machine’s configuration. Types of U Bolt Bending Machines: Manual U Bolt Bending Machine: A basic version where the operator manually bends the rod, typically for small production volumes or custom-sized U bolts. Semi-Automatic U Bolt Bending Machine: Involves some manual input but mechanizes the bending process, making it faster and more consistent than fully manual machines. Fully Automatic U Bolt Bending Machine: Designed for high-volume production, these machines automatically feed, bend, and cut the rods with minimal operator intervention. CNC U Bolt Bending Machine: A computer-controlled machine that offers high precision and can be programmed to produce U bolts of different sizes and shapes in large quantities. Ideal for industrial-scale production. Applications: Construction: U bolts are used to anchor pipelines, secure structures, and fasten heavy equipment to concrete or other materials. Automotive: Used for attaching parts like exhaust systems, leaf springs, and chassis components. Marine: Securing boat engines, equipment, and rigging. Electrical: Fastening conduit or cable management systems. Transportation: Securing loads on trailers or mounting components on heavy-duty vehicles.

Pipe Bending Machine

100,000 - 300,000 Per Piece

1 Piece (MOQ)

PLC, DCS, HMI & SCADA BASED CONTROL SYSTEMS FOR WATER CONTROL MANAGEMENT TRUNKEY PROJECTS (Installation & Commissioning Services) PIPE BENDING MACHINE AUTOMATION SYSTEM INSTALLATION, COMMISSIONING & TESTING SERVICE PROVIDER Details: Automatic Two Axis & 360 degree bend control. Stepper motor interface with PLC & SCADA System. Recipe management for different bend angles for different customers. Automatic Shift wise production reports generation. Auto job turning, clamping & bending for up to 15 nos. of successive cycles

Best Deals from Bending Machine

two axis pipe bending machine

Get Price Quote

We are a well-known Manufacturer and Supplier of Two Axis Pipe/Tube Bending Machine. Two Axes Pipe/Tube Machines : These Machines are NC controlled Machines & are very cost effective having servo facility for Turn Axis, Push axis is Manual, available for Bending of Tubes/Pipes from 4mm OD to 164mm OD Tubes/Pipes. These Machines are generally used in Automobile & Power Transmission Industries. Features : Color LCD Touch Panel for Data Entry and Editing Operation mode-Manual/Semi auto/Fully Auto 15 bends program Large/Multiple program data storage facility Bend arm over ride switch to prevent bend arm/machine collision Programming in mm Program Retrieval by Alphanumeric code, password Hydraulic Mandrel Retraction Servo controls for change of Plane Online/Offline diagnosis mode Built In Hydraulic Oil Cooling system Clockwise Bending

Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

Aluminium Channel Letter Bending Machine

5 Per Piece

1 Piece(s) (MOQ)

pvc pipe bending machine

350,000 Per Piece

1 Set (MOQ)

3-4 Roller Plate Bending Machine

150,000 - 850,000 Per Piece

1 no (MOQ)

Hydraulic Busbar bending machine

Get Price Quote

1 piece (MOQ)

Robot Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

Robot Bending Machine, in which we deal, is loaded with an array of benefits that takes the value of the machine to heights. The machine is acquired from credible manufacturer, who work in accordance with the standards. We are emerging as the promising Supplier of Robot Bending Machine in Pune, Maharashtra. We work in an orderly manner to fulfill the orders for it within the stipulated timeframe.

Bar Bending Machine

Get Price Quote

We are actively engaged in manufacturing and supplying Bar Bending Machine. We carry out our operations from Pune, Maharashtra, India. We use the top quality components and updated techniques for engineering our Bar Bending Machine. Our deft professionals fabricate it with a high level of precision. It is known for its sturdy structure, perfect finish, smooth functioning, and long operational life. We offer it to various industries for specific applications. It is available at a pocket-friendly price.

Cnc 2x Tube Bending Machine

Get Price Quote

We offer cnc 2x tube bending machine. For bending of simple tubes in the automotive, furniture, boiler, plumbing industries. model unit 30cnc2x 65cnc2x 80cnc2x 100cnc2x max. Tube capacity (d x t)* mm 32 x 2 65 x 4 80 x 2 114 x 6 max. Bend radius (clr) mm 120 300 300 500 min. Bend radius in terms of d 1.5d 1.5d 1.5d 1.5d length over mandrel m 3 3 3 3 bend angle range deg 5 - 180 5 - 180 5 - 180 5 - 180 bend speed (accuracy) degs (deg) 50 (â±0.2) 24 (â±0.2) 18 (â±0.2) 12 (â±0.2) dbb speed (accuracy) mms (mm) 400 (â±0.1) 200 (â±0.1) 200 (â±0.1) 200 (â±0.1) pob speed (accuracy) degs (deg) 150 (â±0.1) 100 (â±0.1) 100 (â±0.1) 80 (â±0.1)

Manual Pipe Bending Machine

Get Price Quote

Our product range is subjected to stringent quality control procedures to ensure they are as per industry standards. Our establishment in Pune(India) is well connected by varied modes of transport. Thus, we are capable of reaching patrons with ease. Our precision engineered Manual Pipe Bending Machine has a high utility in making, kitchen utensils, medical equipments, electric equipments, building construction etc.

Pipe Bending Machines

Get Price Quote

Manufactured by the use of progressive techniques, the provided range of pipe bending is delivered by us at clients end within the promised time frame. Product Details : Trouble free functionality Rugged construction Easy maintenance User-friendly Anti corrosive Long lasting nature Industries : Textile Milk industries Machine fabrication Clutches and Brakes Automobile Ink Rubber & tyre plants Chemists Paper Mill Pharmaceuticals We are Manufacturer of Pipe Bending machinesXI, IIX, IIIX Auto & Semi Auto Machines & CNC Types AvailableModel : 0-16 mm, 6-33mm, 6-50mm, 6-50mm, 6-65mm, 6-80mm, 6-100mm, Available Usage : Automotive Product Fabrication Industry As Per Sample Furniture Industries Bar Bending Section Pipe Bending Machine Pipe Bending Machine & ToolingWe are manufacturing of all types of Hydrolic, Semi Auto, Fully Auto, & CNC Type XI, XII, XXI & IV X Machines Tooling Manufacturer of All Tools. 1. Bending Die2. Pressure Die3. Clamping Die 4. Gripper5. Ball main Drill 6. Shoee Die7. Collect

condenser bending machine

Get Price Quote

Electropneumatics makes light duty tube bending and end forming machines for bending of copper and aluminium tubes and sections for the air conditioning, heating and cooling applications. Parts such as evaporator and condenser coils for air conditioners, chest coolers, deep freezers and refrigerators, stainless steel plates for heat exchangers, etc. can be formed on specially designed machines for these applications. They are highly productive machines engineered to fit the customer’s needs. Rigid, high-tonnage specialised hydraulic presses are available for stainless steel heat exchanger plate forming. Since material cost if a large percentage of the component cost, these presses are specially designed for fast operation and low rejection rates.

Hand Operated Metal Sheet Bending Machine

Get Price Quote

sheet bending machine including hand operated metal sheet bending machines, designed for accurate & economical curving, punching, cutting and shearing sheet metal. Staying on top of the competition is key to your company's success and so we pride ourselves on offering you an unbeatable quality of hand operated metal sheet bending tools. We can offer hand operated metal plate bending tool in customized dimensions.Hand operated sheet bending machines for workshop requirements have special importance in metal industries. s supplies hand operated metal sheet bending equipment intended for accuracy in curving. Our tool is also economical in design and expense. We provide moulding component which can be applied for expanded machining activities including punching, cutting, moulding as well as shearing of different types of metal sheets.

metal pipe bar Bending Machine

Get Price Quote

Section Bending Machine

140,000 Per Piece

Bar Bending Machines

Get Price Quote

We are offering bar bending machines. - bar size : 32 to 42 mm available in different models. - manual / automatic

Bar Bending Machine

Get Price Quote

U Bolt Forming and Bending Machine

Get Price Quote

1 Piece (MOQ)

pvc bending machine

Get Price Quote

½” to 1” PVC PIPE BENDING 1-12” to 2” PVC PIPE BENDING 2” to 4” PVC PIPE BENDING Brand : S-INDIA Model No : SI-BEND-2017

Ermaksan CNC Bending Machine

Get Price Quote

Used Bending Machine

Get Price Quote

We are a significant Supplier of Used Bending Machine. Our office is located in Pune, Maharashtra, India. Our offered Used Bending Machine is analysed for its capability and service life so that the prospective buyer gets the full benefit for the cost of the second-hand machine. We offer it to various establishments for specific applications. We make sure that our offered Used Bending Machine is in accordance with the set industrial standards and norms. We offer it at a cost-effective price.

Pipe Bending Machines

450,000 - 825,000 Per Qty

Hydraulic Four Roll Plate Bending Machine

Get Price Quote

We offer high quality Hydraulic 4 Roll Plate Bending Machine to the clients. Hydraulic 4 Roll Plate Bending Machine, offered by us, finds uses in numerous manufacturing industries. Our Hydraulic 4 Roll Plate Bending Machine has features such as overload protection, correction of axial offsets, simple cone bending, and pre bending of sheet edges. Our Hydraulic 4 Roll Plate Bending Machine is suitable for light and medium aluminum or stainless steel plates. Highlights Overload protection Offers simple cone bending Easy to operate

Steel Bar Bending Machine

Get Price Quote

The bending machines are offered in two variants viz. UBM 42 and UBM 52. These powerful units possess the capacity for bending steel bars up to 52mm diameters. They are easy to operate and occupy lesson-site space.

Angle Bending Machine

Get Price Quote

Speedy And Accurate Bends. •Stroke Control On Punch Movement for preset degree of Bend. •Designed Tonnage available throughout the stroke •Inexpensive tooling •Low running cost •negligible maintenance

Cnc Bending Machine

Get Price Quote

cnc bending machine We provide CNC Bending Services, Sheet Metal Bending Services , CNC Bending Machine Works ,Pune, Maharashtra, India.

stirrup bar bending machine

Get Price Quote

pipe bender machine

Get Price Quote

S.B.Enterprises have come out as the foremost trader and supplier of an excellent quality Pipe Bender Machine. Apt for bending purposes, this machine is well known among our clients who are situated across the nation. Features: Robust design Optimum performance Long service life