Nano Blender

167,000 Per Piece

1 Piece (MOQ)

Y Cone Blender

Get Price Quote

We ensure that the products we deliver will remain completely damage free as we make use of the finest quality packing material. Moreover, the entire process is supervised by the experts. We guarantee to make on time delivery, as we have an extensively spread network of logistic facility providers and dealers. Features: High-performance Robust construction Easy operations & maintenance

Best Deals from Blender

Ribbon Blender

34,500 - 156,000 Per Unit

1 Unit (MOQ)

Paddle Blender

Get Price Quote

AVM offers customized Allied Equipments / Systems with variety of Configurations. Blenders / Powder Mixers Equipments configured for Batch or Continuous Operation. Capacities as per system requirements. Paddle Type Blenders. Ribbon Type Blenders. Special Rotor Type Blendors. Double Cone Blenders. Double Shaft Paddle Mixers. Online Product Blenders with controlled liquid dosing as per system requirements. Liquid Feed / Slurry Preparation Systems Agitated Reaction Vessels. Vessels with Heating, cooling, sparging mechanism. High Speed Blungers. Material Handling Systems Double Flap Valves: Motorised / Counterweight type. Rotary Air Lock Valves : Drop Through / Blow Through type. Rotary Feeders. Screw Conveyors. Pneumatic Conveying Systems: Lean Phase Suction Type. Pneumatic Conveying Systems: Lean Phase Positive Pressure Type. Cleaning In Place (CIP) Systems Single Tank System / Three Tank System. Motorised Winch system for large vessels cleaning. Wall flush nozzles for cleaning od ductings, equipments. Fully automated systems with PLC / DCS & SCADA.

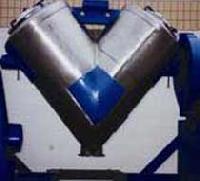

V Blender

Get Price Quote

We manufacture the finest quality V-Blender, which comes with two cylindrical sections adjoined at an angle of around 90o and its mixer rotates in about a horizontal axis. Our V-blenders are specially manufactured for batch operation. The contact and non-contact part is made up of S.S 316/S.S 304 and S.S.304. We are distinguished as one of the prim Manufacturers, Exporters, and Suppliers of V-Blender in India. Available In : Liters : 5 liters to 1500 liters Features : Balanced cone to avoid excessive loadDurable gearbox and Flameproof motor Easy to load and unload material Easy to clean and maintain Used In : Pharmaceutical Industry Chemicals IndustryFood IndustryFertilizers IndustryPlastics Industry

gravimetric blender

600,000 Per Piece

1 Piece (MOQ)

Stainless Steel Powder Blender

300,000 Per Piece

1 Piece (MOQ)

Conical Blender

Get Price Quote

The Nauta Mixer has a conical container which houses a constant flight screw.This screw revolves on its own axis and also around the cone wall.Material of diverse shape, size and densities are homogenously mixed without any deprivation. Application : • Dry Blending, Dry Blending with Liquid Spray. • Features: • Low Power Consumption • Short Mixing Time • Low space require • Gentle mixing action

Double Cone Blender

Get Price Quote

To make our transactions secure, we allow our clients to make payment through both offline and online mediums. we are a quality-conscious firm and for maintaining product quality, we consider several measures so as to ensure that only flawless lot reaches the buyers. Applications : Food Cosmetic Chemical Pharmaceutical Features : Electric controls panel with cycle time Fixed baffles provided for lumps braking The product container rotates on sped 8 RPM Enclosed rigid drive with reduction gear box and motor Safety reeling provided for revolving area of product container Charging hole with hinged lid with seal for charging and cleaning Product container having discharge with butterfly valve and man hole

Industrial Blender

Get Price Quote

We are instrumental in manufacturing, supplying and trading a qualitative array of Industrial Blender. Manufactured using high quality material, our range is applauded for its longer service life, noise free operations and sturdy construction. Furthermore, clients can avail these products from us in various specifications at Competitive rates. Features:• Noise free operation• Robustness• Longer service life

Blender

Get Price Quote

We offer different type of Blender Ribbon Blender "U" type Ribbon Blender "O" type Conical Ribbon Blender Advantage : General mixing action with minimum power Optimum mixing time Accurate mixing & with minimum to zero retention

blenders

Get Price Quote

We manufacture blenders using premium grades of stainless steel and alloy steel, our range of vessel and ribbon blenders are one of the most mixing common devices used in process industries. These ribbon blenders comprise helical ribbon shaped blades that rotate close to the edge of a U-shaped vessel that makes them applicable for high viscosity fluids and dry blends.

Volumetric Blender

Get Price Quote

Design Type Standard, Customized Condition New Features: Consistent dosing brush less motor PLC supported control Saving on additives Inclined Screw Setting for accurate dosing Optional: Loader mounting provision

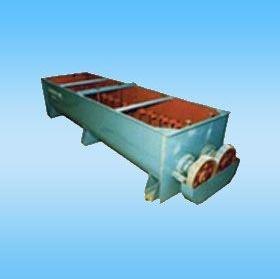

Horizontal Ribbon Blender

Get Price Quote

Horizontal ribbon Blender is widely used in chemical, pharmaceuticals, food, and construction line. It can be used to mix powder with powder, powder with liquid, and powder with granule. Under the driven of motor, the double ribbon agitator mix the material quickly. This ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customer should choose the model according to the output per batch. Technical Parameter: Capacity: 25KG to 2000KG Mixing time: 30-60minspower: 0.7 5 KW-23 KW (varies as per capacity) Material: 316L, 304, 304L, Mild Steel Features - Blending with low RPM- Both Side walls are Sealed- Four Bearing Construction - Liquid Addition arrangemen Working Principle Blender consists of transmission parts, double ribbon agitators and U-shape cylinder. In the direction of rotation, the outer ribbon pushes materials from both ends to the middle, while the inner ribbon pushes materials from the middle to both ends. Ribbon wind with different angle direction carries the materials flowing in different directions. Through continuous convective circulation, the materials are sheared and mixed thoroughly and quickly. Applications - Chemical- Food- Pharmaceutical- Fertilizer- Plastic- Animal Feed- Cosmetic

Ribbon Blender

Get Price Quote

blenders

Get Price Quote

They come in many different models but what is important is that the hand blender you buy will meet essential requirements and will be able to perform tasks as necessary. Most handheld blenders are able to do basic mixing capabilities while others can do more because of its extra attachments. competitive prices. A hand blender is a great kitchen tool to have particularly if you will be spending a lot of time in the kitchen trying a variety of different recipes.

Ribbon Blenders

Get Price Quote

Ribbon Blenders are best suited for mixing, granulation and homogenizing batch process. It handles a range of applications from all types of powders including free flowing to cohesive and moist powders, bulk dry materials to wet cakes and slurries. Ribbon Blenders are very sturdy and robust. They consists of a conical Vessel with dished / flat head. The central agitator shaft is driven from top end with gear reducer. A double helical ribbon agitator in the vessel moves the product upward along the outer wall and releases it downward into cavities developed in the middle, simultaneously material is horizontally distributed by the mixing arm and is optimally homogenized. Mixing time is depending on the agitator speed. In general mixing time is three to four times shorter than the mixers working with a rotating screw. The drive and bearings are kept outside of the vessel, no gears or seals in the product compartment. The rotating central agitator shaft does not have bottom bearing support there by eliminating any dead spots or difficult areas to clean and there is no danger of product contamination. Discharge of the product is fast and simple as full bore open. Design Options : • Models with single or double helix. • Net capacities for 20 to 25000 litres. • IVarious Material and surface treatment available depending upon product characteristics • Cutting rotors for breaking down of agglomerates • Liquid adding by ISP system. • Heating Cooling jackets with insulation

Ribbon Blenders

Get Price Quote

Excel Project , Ribbon Blender are mostly used by Chemicals, Plastic, Pharmaceutical, Paints and food industries. The Ribbon Blender does homogenous mixing of powder and semi-wet material of different densities. The ribbon blades of different designs are used to suit the need of different materials. The Blender consists of a Semi-cylindrical shell inside which rotates a Shaft fitted with spiral inner and outer ribbons.

Screw Blenders

Get Price Quote

Our Screw Blenders are widely used by the clients as their blending action is gentler than any other horizontal blenders. These require low power as the active blending volume is less in comparison to that of the horizontal blenders. Blending depends on the variegated travel speeds of product particles in the conical section of the vessel. The screw collects the material from the bottom section of the vessel and spreads it over the upper sections.

Blender

Get Price Quote

Ribbon Blender

Get Price Quote

plough blender

Get Price Quote

Typical applications include homogenous mixing of pastes, rubber, heavy plastic mass, food, pharmaceutical, chemicals etc.The overlapping of shovels coupled with its shape and the high speed of the ploughs produces good mixing action and high turbulence.The arrangement of mixing tools is the result of many years of development by RAJ process equipments combined with experience based on mixing trials and practical scientific work.

electric blender

Get Price Quote

Capacity 3. Blendor available in different capacity 25kg, 50kg, 60kg, 75kg, 100kg, 200kg, 500kg, 1000kg etc. Power Requirement 230V AC 1 Phase, (up to 75 kg capacity) 420 V AC 3 phase (from 100 kg & above)

Ribbon Blender

Get Price Quote

1 piece (MOQ)

Working principle & features render’s ribbon blenders is design to provide high mixing efficiency, blending small proportions into large stocks. Ribbon blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced. A wide variety of configurations, for either batch or continuous mixing, are available. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing efficiency. Efficient mixing also provides good heat transfer through optional asme code designed jackets for heating or cooling applications. The compact and robust construction dust proof operation ensures their negligible running costs. We can offer these in various customized sizes/finishes. we provide custom made size design of the ribbon blender to meet your specific mixing requirements. Mixing vessels can be standard u-shape or cylindrical depending on internal pressure or vacuum requirements. Material finishes available ranging are from industrial coatings to dairy grade polishes.

Ribbon Blender

300,000 Per Piece

1 Piece (MOQ)

Industrial Powder Blender

Get Price Quote

To mix dry powder & granules, these Industrial Powder Blender are considered very suitable and effective. These cone blenders are extensively used for cosmetic powder, food, chemicals. It is an efficient and versatile machine used for mixing powder and granules homogeneously. All the contact parts of the blender are made from materials with grades as required by customers. Our blender offers uniform mixing and easy discharge of material.

Octagonal Blender

Get Price Quote

We offer octagonal blender, ribbon blender.

Ribbon Blender

150,000 - 200,000 Per Piece

Ribbon Blender

Get Price Quote

air classifier mills

Industrial Blender

Get Price Quote

Industrial Blender, Bagasse Feeder, industrial fabrication system