Venturi Scrubber

Venture Scrubber with vertical separator is a perfect system for pollution control. This unit can be installed before ID fan or after ID fan suitable as per the existing boiler layout, In venture scrubber, the gas steam enters from the top side and passes down the converging section to the throat. The water is injected from the top of the throat in film format, dust particles of the gas caught in this section and deliver in the bottom section with water and come out as slurry from the bottom hopper of the vertical cyclone separator. Gas enters in the vertical separator with a cyclonic entry this helps to separate gas and water particles in vertical vessels. Height of vertical vessel is designed in such a way that gas and water particles shall separate out and clean gas goes to ID Fan. Please note as per our design more than 25 units are working in India for 20 TPH to 100 TPH Bagasse fired boiler. We can provide total engineering consultancy of this system to suit your requirement. We provide total detail drawing of venture scrubber system with slurry piping/water piping / RCC tank details. All bought out specifications to reduce the cost. The Schematic diagram and the General Arrangement Drawing are shown below for your ready reference

Application : Scrubbing

Weight : 100-1000kg

Voltage : 220V

Automatic Grade : Automatic

Warranty : 1yrs

...more

Stainless Steel Expansion Bellows

1,500 - 3,500 Per Piece

Material : Stainless Steel

Shape : Round

Thickness : 10-15mm

Color : Grey

Feature : Cost-effective, Durable

Technics : Casting

...more

SCREW FEEDER

Application : To feed Bio Mass/Coal

Capacity : 500Kg/Hr to 5000Kg/Hr

Type : U through

...more

Rotary Bagasse Feeder

Application : To feed Bagasse

Capacity : 500Kg/Hr to 5000Kg/Hr

Type : U through

...more

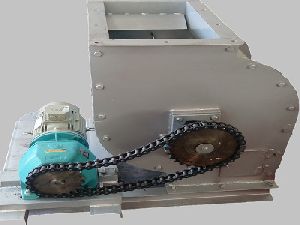

Rotary Airlock Valve

150,000 Per Piece

Material : Casing – IS 2062 MS

Media : Air

Rack and Pinion Slide Gate

Material : Mild Steel

Shape : Rectangular

Application : Industrial

Color : Silver

Feature : Anti Corrosive, Durable

Finishing : Polished

...more

Pneumatic Spreader

Capacity : 500Kg/Hr to 5000Kg/Hr

Multicone Dust Collector

Application : To collect dust particles form boiler

Mild Steel Expansion Bellows

Material : Mild Steel

Shape : Round

Color : Grey

Feature : Cost-effective, Durable

Technics : Casting

...more

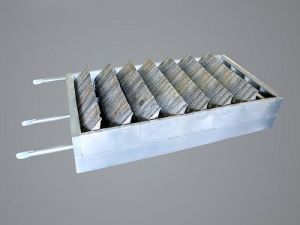

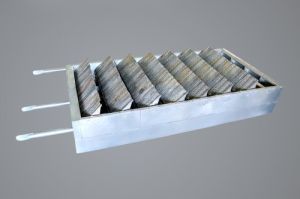

dumping grate

Type : Two stage type

Dumping Fire Grate

Country of Origin : Made in India

Duct Damper

Material : Metal

Shape : Circular, Square

Thickness : 5-10mm

Application : Ventilation

Color : Shiny Silver

Feature : Adjustable, Corrosion Resistance, Durable

...more

Drag Chain Conveyor

Application : Boiler Ash Discharge

Deaerator Tank

Material : SS

Control Panel Cabinets

Body Material : Mild Steel

Coal Spreader

Capacity : 500Kg/Hr to 5000Kg/Hr

Biomass Stone and Sand Separation System

We are one of the prominent manufacturers and suppliers of stone and sand separation system in Maharashtra. With years of experience in the industry, we offer our clients an exceptional range of Sand & Stone Separation Systems in terms of capacity that are quality approved in nature and are in adherence with the set quality standards of the industry. This system is used to separate stone and sand mixed in the biomass fuel such as soybean husk, rice husk, etc. The system is designed with basic four equipment’s. Screw feeder Vertical cyclone Rotary Air Lock Valve ID Fan Initially the biomass fuel is feed to the screw conveyer through the hopper. The screw conveyer carries the dried biomass and discharges it in the Y Shoot which is attached to the discharge point of the Screw conveyer. The Slanting screw conveyer is attached with one more screw conveyer under it. The smaller screw conveyer attached to the below side of the bigger screw conveyer, collects and carries the mud / sand present in the biomass fuel to the discharge point. The mud / sand which is collected through the discharge point of the smaller screw conveyer is ultimately taken away to the dumping point with the help of a trolley. Now the biomass along with the big stones enters in to the Y shoot. The Y shoot is connected to the Vertical cyclone with a connecting pipe. The biomass entering the Y shoot and is sucked in to the vertical cyclone with the help of the ID fan. The process at the point of the Y shoot helps to separate the stones present in the biomass fuel. The stones present in the biomass are collected at the discharge point of the Y shoot. The clean biomass is entered in to the vertical cyclone and is discharged on the belt conveyer through a Rotary Air Lock Valve (RALV). RALV prevents the reverse entry of air in to the vertical cyclone. Ultimately the clean fuel enters the Boiler increasing the capacity and efficiency of the boiler. Stone and sand separation system is designed with precise engineering. This system is tailor made as per requirement of the customer and capacities of the boilers. Features and Gains. Designed with precise engineering The system is tailor made depending on requirement of the customer and capacities of the boilers. Increases capacity and efficiency of the boiler Reduces work load of the workers. System is provided with all supporting structure reducing the work load at the site.

Application : Used to Separate Stone and Sand Mixed in the Biomass Fuel

Body Material : Metal

Surface : Polished

Application : Industrial

...more

Air Preheater

Material : Metal

Application : Power Generation, Food Process Industry

Weight : 100-1000kg

Color : Grey

Automatic Grade : Automatic

...more