brass brazing fluxes

Get Price Quote

With substantial warehouse that is sprawling over large area, we have the capability to partner with management in performing the detail processes that require handling of the tasks such as sourcing, inspection, internal replenishment to picking positions, packing and shipping. Our facility in pune(india) is well connected by a variety of modes of transportation. Thus, we are able to reach customer anywhere.

Silver Brazing Rods

Get Price Quote

Silver brazing is a joining process whereby a non-ferrous filler metal, alloy is heated to melting temperature (above 800°F) and distributed between two or more close-fitting parts by capillary attraction.

Best Deals from Brazing Equipment

gas welding rods

Get Price Quote

Silver Brazing Alloy

Get Price Quote

We are offering silver brazing alloy & silver brazing wires. As silver brazing alloys are easy to use, possess high strength impact with short melting ranges, free flowing and versatile. They have outstanding flow characteristics and mechanical properties. These are available in forms of wire, foils or shims, preformed wires or strips, granules, rings and paste or powder. Besides, these can be customised as per clients specifications and applications. Uses automotive industry uses brazing extensively, especially for brazing aluminum radiators, which use tube-to-fin and tube-to-header joints. Brazing is also used in pipe and tube applications to extend length, fabricate shapes, join dissimilar materials, and to ensure a water or pressure tight joint. Common base metals include aluminum and its alloy, copper and alloy, steel and stainless steel. Brazing applications extend to microwave reflectors, satellites, cameras, and other sophisticated instrumentation. Common base metals used include oxygen free copper, nickel, stainless steel, copper- nickel alloy, iron-nickel-cobalt alloys, and tungsten. Products in silver brazing alloys silver brazing rods & foils ranges: 50%, 43%, 35%, 30%, 14%, 5%, 2% packaging details description packing length (mm) size (mm) weight tig rods corrogated box 500 3.15, 2.5, 2.0, 1.6 1 kgs mig wire plastic spools - 2.0, 1.6, 1.2, 0.8 on request shim foil - - - on request we cater to your welding requirements of silver brazing alloys in the form of agrawal co. ( as per is 2927) silver brazing alloys. For more details, fill our enquiry form.

Stress relieving of welded mould

Get Price Quote

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

aluminium gas welding rods

Get Price Quote

aluminium gas welding rods:Brand : Available in Reputed brands, Electrodes for Low Alloy Heat Resistant Steels (AWS A5.5): E7010-A1, E8016-B1,E7018-A1, E-9015-B9. We also specialize in manufacturing and supplying welding consumables for fabrication, maintenance, repair welding & hard facing surfacing applications.

Bronze/Brass Brazing Fluxes

Get Price Quote

A powder type pink flux for braze welding /brazing of copper alloys, carbon & galvanized steel, carbides. Easy residue removal. High fluxing activity with good wetting and spread. Excellent visibility while brazing. (no sodium glare). Application area : automobile industries, cycle manufacturing, furniture industries, tool manufacturing industries & home appliances.

silver brazing flux powder

1,500 Per Kilogram

Silver Brazing Flux Powder

Get Price Quote

aluminium brazing flux, Brazing Ring, brass brazing rod

silver brazing alloys

Get Price Quote

We are offering silver brazing alloys, silloy ncd / sn / si ag brazing flux silloy 9999 ncd 99-100 silmux - t silloy 9092 ncd 90-92 silmux - t silloy 6770 ncd 67-70 silmux - t silloy 6366 ncd 63-66 silmux - t silloy 5861 ncd 58-61 silmux - t silloy 5356 sn-ncd 53-56 silmux - g silloy 5659 sn-ncd 56-59 silmux - g silloy 5659 sisn-ncd 56-59 silmux - g silloy 4346 sn-ncd 43-46 silmux - g silloy 4346 sisn ncd 43-46 silmux - g silloy 4346 ncd 43-46 silmux - t silloy 4245 ncd sp 42-45 silmux - t silloy 4244l ncd 42-44 silmux - g silloy 3841 ncd 38-41 silmux - g silloy 3639 ncd 36-38 silmux - g silloy 3335 sn-ncd 33-35 silmux - g silloy 3235 ncd 32-34 silmux - t silloy 2831 sn-ncd 28-31 silmux - t silloy 2831 ncd 28-31 silmux - t silloy 2326 ncd 23-26 silmux - t silloy 2224 ncd sp 22-24 silmux - t silloy 1820 si-ncd 18-20 silmux - t silloy 1619 si-ncd 16-19 silmux - t silloy 1618 ncd 16-18 silmux - t silloy 1012 ncd 10-12 silmux - t silloy 406 ncd 4-6 silmux - t silloy 406 si-ncd 4-6 silmux - t silloy 102 si-ncd 1-2 silmux - t silloy 101 si-ncd 0.5-1.5 silmux - t.

Copper Gas Welding Rod

Get Price Quote

Copper Brazing Rods

20 Per Piece

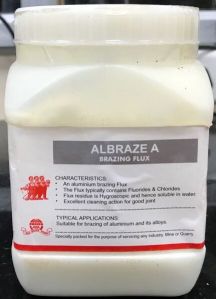

Brazing Flux

Get Price Quote

Typical Applications : Brazing of Al and its alloys Features : Aluminium brazing flux Contains fluorides and chlorides Excellent cleaning action Flux residue is hygroscopic, hence easily soluble in water.

copper brazing rod

Get Price Quote

copper brazing rod, binding tape, cable channel, Cable Gland, cable saddle

brazing welding equipment

Get Price Quote

brazing welding equipment, CO2 Welding Machine, Press Components

Brazing Rings

Get Price Quote

Brazing Rings, U Bend, straight tube, U Bend with Brazing Rings

silver brazing alloys

Get Price Quote

silver brazing alloys, Alloy Fittings, unequal angle bar

silver brazing alloys

Get Price Quote

silver brazing alloys, Manganin Wires, DC Shunt UPS, shunt resistors

brazing equipment

Get Price Quote

brazing equipment, Auto Tig Feeder Welder, air plasma torch

brazing torch

Get Price Quote

brazing torch, Stainless Steel Flux Cored Wire, Messer Gas Economiser