Fly Ash Brick Making Machine (SHBM- 1)

Get Price Quote

Avail from us High Pressure Center Press Fly Ash Brick Making Machine (SHBM- 1) that is based on the latest technology. The Hydraulic Operated Semi Automatic Fly Ash Brick Making Machine with Hydraulic Power Pack with Feeder System is meant for feeding raw material. An efficient Oil Cooling System to cool down oil even Press works with Hydraulic Valve. Buyers can purchase the Fly Ash Brick Making Machine at market-leading price from us.Specifications : Maximum High Pressure : 70 Tones. Oil Tank : 220 Ltrs. Power Pack : 7.5 H. P 3 Phase Motor Brick Size Mould : 6" × 4" × 9" (2 Nos. Operation) Capacity : 2500 To 3000 Bricks 8 Hr. Shift Brick Size Mould : 4” × 3” × 9” (3 Nos. Operation) each side Capacity : 3500 To 4000 Bricks 8 Hr. Shift

Fully Automatic Fly Ash Brick Making Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Brick Making Machine

Fly Ash Brick Press Machine

6 Per 6.00 Piece

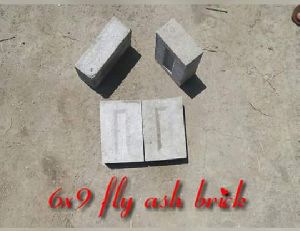

4x9 Fly Ash Bricks / Colour - Grey Material Use - Crush Sand / Cement / Fly Ash . Rate Ex - Factory + GST + Transport

Clc Plant

Get Price Quote

01 Set(s) (MOQ)

We are offering clc plant, clc block plant, clc block making plant, clc wall making plant, clc light weight brick making plant, clc block machine , low cost clc plant, best quality clc plant, foam generator for clc plant, clc mixer, clc density checker, belt conveyor for clc plant.

Fly Ash Brick machine

Get Price Quote

We are offering fly ash brick machine. A one hydro fly ash brick machine. Fully otometic .one time 10 piss brick s-110+230+75 mm. Heavy duty presh bodi.70 tone capeshity.oil tank 400lts .7.5 hp moter.trolley hopper malay ment. Pen mixer 500 kg capesit.7.5 hp moter & heavy duty gerbox & cancer belt.18' 2 hp moter & gerbox. (add to fully otomet

Fly Ash Brick machine

800,000 - 3,000,000 Per Piece

Semi Automatic and Automatic Fly Ash Brick /Block & Paver making machine.

Fly Ash Brick Making Machine

Get Price Quote

We are offering fly ash brick making machine. Our organization offering of advanced semi automatic high pressure hopper machine. We believe in innovation therefore our engineers are given best opportunities to innovate finest designs. Semi automatic with high pressure machine offered by us is an extremely important and useful machine made in compliance with industrial standards. These machines offer higher efficiency and better quality. With below given features semi automatic machine that we offer is available. fly ash brick:- standard, brick size- 230x110x75=8 nos other brick size-230x150x80=6 nos stoke (20 seconds 8 bricks) high pressure of machine 70 tone power (motor) 7.5 hp for high pressure of machine oil tank 200 litter capacity. 3 hp motor with vibrator. 2 hp motor with conveyor belt semi automatic with high pressure machine:- no of 1 pan mixer with 7.5 hp motor capacity of raw material mixing, 500 kgs mfg capacity 1500 per hour, water cooling 1 hp motor, 1 mould extra with machine total power use all units use 21 hp free fitting at your place (only in india) 1 year warranty.

Fly Ash Brick machine

Get Price Quote

AHP Machines are the leading manufacturer of fully automatic fly ash brick making machine, our machine has features like Automatic Raw material weighing, Auto mixing, Batching plant, Silo’s, Discharge of finished bricks through Conveyer for fast production . Raw materials used for the production of fly ash bricks is fly ash, sand, lime and gypsum or cement.

Fly Ash Brick Making Machine

Get Price Quote

Clc Plant

Get Price Quote

Fibrocrete block is “Cellular Light weight foam fibre Concrete block” or CLC + “Light weight concrete” across the world with its greater advantages from last 40 to 50 years. The basic Fibrocrete is made from mixing aqueous foam which is produced from foam generators into slurry of fly ash or sand with Cement and Fibre in a precise mixing in foam concrete mixer for accurate mixing without disturbing chemical and physical properties. The final mixture results in many tiny air voids uniformly distributed throughout the batch which creates cellular structural material densities ranging from 400 kgm3 to 1800 kgm3 with compressive strengths between 2 Nmm2 to 12 Nmm2. The Precise controls of the volume of air voids in foam concrete result in controlled densities and strengths of foam concrete. Production Setup capacities of 50 100 150 m3 per day are available in complete Automatic and Semi-automatic mode of operation.

Cellular Lightweight Concrete Plant

Get Price Quote

Fibrocrete block is “Cellular Light weight foam fibre Concrete block” or CLC + “Light weight concrete” across the world with its greater advantages from last 40 to 50 years. The basic Fibrocrete is made from mixing aqueous foam which is produced from foam generators into slurry of fly ash or sand with Cement and Fibre in a precise mixing in foam concrete mixer for accurate mixing without disturbing chemical and physical properties. The final mixture results in many tiny air voids uniformly distributed throughout the batch which creates cellular structural material densities ranging from 400 kgm3 to 1800 kgm3 with compressive strengths between 2 Nmm2 to 12 Nmm2. The Precise controls of the volume of air voids in foam concrete result in controlled densities and strengths of foam concrete. Production Setup capacities of 50 100 150 m3 per day are available in complete Automatic and Semi-automatic mode of operation.

SOFT MUD BRICK MOULDING MACHINE

Get Price Quote

his machine is based on Mould Chain (MC) principle which makes continuous and high speed production of green (raw) bricks possible. With every stroke, green bricks are ejected out of a mould on a metal pallet. It consists of a mixer, a mould chain, a press block, a mould washing station and an all-side sander (including exhaust box). Final adjustment of water content in the raw-mix can be done by adding 5 to 7 % water in the mixer.Loaded pallets coming out of the machine are carried to drying sheds and bricks remain on pallets till they achieve leather-hardness. Empty pallets are returned back to the machine.At present, ‘Ishtika’ Mixerpress has 4 Models – Model MC9, MC8, MC7 and MC5 – all based on mould chain principle and differing only in the number of cavities per mould.

Clc Plant and Machinery

Get Price Quote

Our clc plants are designed to manufacture blocks and panels of various densities from 450 to 1200 kgm3. We provide customized solutions as needed by our customer, so as to give our customers a full range of production capabilities. Our range of products.. Fully-automatic clc plants semi-automatic clc plants manual clc plants portable clc plants clc plantmachinery and equipments for more information, please visit our website.

Concrete Brick Cutting Machine

580,000 Per Piece

Clc Plant, Belt Conveyor

Get Price Quote

We are manufacturer of clc plant-mixture, foam generator, gear box, belt conveyor,compressor, control panel. Celluler Light Concrete Blocks are todays need We Can plant all machines regarding to it.

Fly Ash Bricks Machine

Get Price Quote

We are the supplier of fly ash brick making machine we have the machine for concrete bricks aac blocks machine and pavers.

Fly Ash Brick machine

Get Price Quote

10 Piece (MOQ)

We are offering fly ash bricks machine, save labar cost low cost.

Fly Ash Brick Making Machine

Get Price Quote

We are offering fly ash brick machine, fully automatic brick making machine having capacity 6000to8000 bricks per day, plc control + hydraulically operated. Having press 60 to 70 ton load.

clc brick making machine plant

Get Price Quote

clc brick making machine plant, automatic fly ash bricks making machines

bricks cutting machine

Get Price Quote

bricks cutting machine, Industrial Products, Industrial Motors