Aluminium Pressure Die Casting Machine

5,000,000 Per Piece

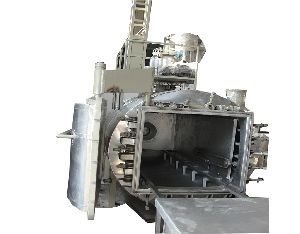

Low Pressure Die Casting Machine

Get Price Quote

Being a high-flying name in this arena, we have developed a common network that links bank accounts and provide monetary exchange using bank deposits. We keep a stern check while the product is being developed to make sure that we deliver only flawless range.Features : Low maintenance Sturdy design User friendly Dimensional accuracy Strong construction Long functional life

Best Deals from Casting Machine

die casting tool

Get Price Quote

We are situated in Maharashtra(India) and our well-developed network assists us in meeting the exact requirements of the clients. With our modern transportation facility, timely and safe deliveries are guaranteed with us.

Epoxy Mixing Cum Casting Plant

Get Price Quote

Overview Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a thermosetting polymer. During the setting process, the liquid monomer polymerizes into the polymer, thereby hardening into a solid. Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement. The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity inside a vacuum chamber. The casting is done in a vacuum chamber to extract the air which avoids formation of air bubbles. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Features : Mixing chamber for mixing of resin, with hardener, accelerators, pigment and filters, of capacities from 5kg to 1000kg, designed for high vacuum degassing. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. The plants can be offered continuous production process. Applications : CT and PT manufacturer Dry type transformer etc

Plastic castings plant

Get Price Quote

Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required.

Centrifugal Casting Machine

200,000 - 300,000 Per piece

1 Set (MOQ)

Hydraulic Die Casting Machines

250,000 Per Piece

Grid Casting Machine

Get Price Quote

Product features horizontal cutting – reduce grid deformation rate after cutting process precise thickness shaping- achieve high precision and consistency of plate thickness ,and better flatness humanized design- human-computer interface, high automation intelligence centralized lead supply system- various combination from one for 1 to 12 main machines heating method of melting pot- gas-he.

Die Casting With Top Punch Machines

Get Price Quote

Features• Pattern Size - 1200 * 1200mm• Side Mould Stroke - 300mm• With Top Punch - 400mm Stroke• Proportional Control Valve Tilting - 0-90° • 7.5HP Powerpack

Gdc Machine

Get Price Quote

We are offering gdc machine. renu enterprises was established in august 2010 & it started its manufacturing of gdc machines, gdc & pdc dies & machining activities at this location after installation & commissioning of all the machinery and equipments required for the set up. This is a firm with the 15-20 years experience and good knowledge in the design & development of tooling & the design of machines. Renu enterprises is involved in the machining components for automobile, process and other engineering industries at present.

casting plant

30 Per Piece

Intake Manifold Gravity Die Casting

Get Price Quote

Gravity Die Casting Machine

120,000 Per Piece

Vacuum Casting Plant

Get Price Quote

Die Casting Trimming Tool

95,000 Per Piece

low pressure die casting

Get Price Quote

Pressure Die Casting Tools

Get Price Quote

We are offering pressure die casting tools. We deal in various types of pressure die casting tools in india.

Epoxy Mixing And Casting Plant

Get Price Quote

We are counted amongst the foremost Manufacturers and Suppliers of Epoxy Mixing And Casting Plants which are highly demanded in the market. We have gained expertise in this field and offer efficient Epoxy Mixing And Casting Plants. These Epoxy Mixing And Casting Plants are manufactured from superior quality raw materials and components which impart strength and durability. We offer our Epoxy Mixing And Casting Plants at economic prices. Capacity from 20kg to 500kg The Plant Consist of Mixing Chamber (M.S or S.S)Shroud box assemblyPouring chamberVacuum pumping systemControl console Mixing Chamber Mixing of resin hardener with accelerator will be done thoroughly by anchor type stirrer with stationary blade rotating at speed 70 � 80 RPM. The mixing chamber is surrounded by oil heating jacket with precise temperature controlling arrangement. Water jacket is provided surrounding to heating jacket for chamber cooling as required. Shroud Box This unit connects mixing chamber and pouring chamber in which Teflon ball and Sleeve arrangement is provided for pouring the mix under vacuum into moulds in pouring chamber. Pouring Chamber (Insulate) Chamber shape : Cylindrical or RectangularHeating : Air heating to prevent heat loss during pouringDoor : Circular or RectangularDesigned to : Vacuum and also desired pressure as requiredIsolating valve between mixingChamber and pouring chamber : A special type gate value of sai guru make.Rotating cone : By geared wheels rotating 360 degreeTrolley : Adequate capacity trolley with moving arrangementTemperature Indicator : Digital Type Vacuum Pumping System A designed vacuum pumping system by rotary oil sealed pump or combination of roots Rotary vacuum pumps are adopted and connected to mixing chamber , shroud box and pouring chamber through effective hardner cum particle trap by 100% leak proof valves of our own make. Control Console Necessary electrical instrumentation with digital display of temperatures, emergency stop button equipped accessibly for easy operationA mimic diagram provided on control panel for viewing various functioning of events Accessories A suitable platform railing and paras ladder provided for suitably for easy workingSet of Spares will be given with the plant

Gravity Die Casting Machine

Get Price Quote

Casting weight - 93 kg, ANoy - Alsi7Mg (LM - 25), Job size : Dia - 800, Length - 800 mm Special process involved - HMC Machining, Helium Leak Proof Used in - Instrument Transformer

COMPACAST Low Pressure Die Casting Machine

Get Price Quote

Equipment designed for high efficiency, high productivity & high die clamping force Rising Pressurization Characteristics" using servo control to control the pressurization cycle precisely. Data Management, Analysis system, Fault diagnostics & entire PLC control enable higher efficiency & control. Ideally suited for high quality production of Alloy castings like wheels, steering columns etc. Can be equipped with Robotic casting handling.