Zinc Pressure Die Casting

430 - 450 Per One

Pressure Vessels

50,000 - 500,000 Per INR

1 Nos (MOQ)

Best Deals from Casting Parts

Pressure Vessels

Get Price Quote

We are a Manufacturer and Supplier of Pressure Vessels from Pune, Maharashtra. We offer highly durable Pressure Vessels, after assuring high quality in the same. Also, Pressure these Vessels provided by us are easy to use and maintain. The company makes high strength Pressure Vessels available at affordable prices. Highlights Immaculate finishRobust constructionLonger service lifeMinimum maintenance

Pressure Vessels

Get Price Quote

Crankcase Castings

Get Price Quote

The Crankcase Castings, provided by us, are manufactured using the best available grade of raw material as per customer requirement. Purchasers can place wholesale or retail orders with any time of the year and expect timely arrival of deliveries. Supported by an ultramodern packaging unit, we pack our products with premium materials and ensure their longevity. Courtesy our unit, we can provide customized packaging solutions too.

Aluminium Patterns Dies

Get Price Quote

Located at Pune(India), we are reckoned for providing excellent array of products throughout the country. We stringently follow automated warehousing system that helps us in meeting the safe storage requirements. Thus, we ensure zero damage to the products till the final dispatch.

Vacuum Castings

Get Price Quote

Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required.

Aluminium Gravity Die Casting

340 Per Kilogram

200 Kilogram (MOQ)

Aluminium Laser Cutting Die

Get Price Quote

30 Series Die Cast L Bracket for T slot Aluminum Profiles

15 - 35 Per Piece

1000 Piece(s) (MOQ)

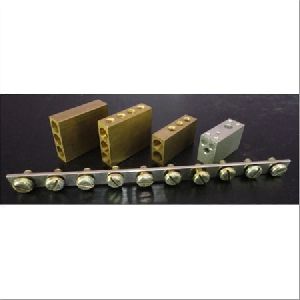

Brass Electrical Components

Get Price Quote

100 Piece (MOQ)

Pressure Vessels

Get Price Quote

01 Piece(s) (MOQ)

pressure vessels are designed and manufactured in accordance with asme viii div 1, and other similar international pressure vessel construction codes for the chemical, petro-chemical, pharmaceutical, cosmetic, food and beverage industries.vessels can be designed for internal and external pressure and vacuum conditions.further options include fatigue life design, thermal analysis and finite element analysis (fea). materials of construction include:stainless steels 316/316l, 304/304l, 317l, 321, 904l, duplex, super duplex, incolloy & monel, clad (explosion bonded) welding processes include tig and smaw, mig, flux cored (fcaw) quality controls throughout the manufacturing process ensure plant integrity and customer satisfaction. With all work being carried out to the standards in accordance with customer and design code requirements by our highly skilled craftsmen and technicians inspection capabilities include radiography, ultrasonic, positive material identification (pmi), mpi and dpi. As well as carrying out hydrostatic testing and surface finish roughness measurements. comprehensive documentation packages are supplied with each vessel upon completion.including declaration of conformity, design approval certificates, drawings, calculations, material certificates and data sheets, ndt reports, hydrostatic test certificates, weld procedures and welder qualifications

Pressure Vessels

Get Price Quote

Owing to our wide domain experience, we make available high capacity Pressure Vessels. These Pressure Vessels designed with precision and in accordance with standard specified in ASME Section VIII Div I. Our Pressure Vessels are sturdy in construction and remain in use for a long time. We make available wide range of Pressure Vessels in specifications as specified by the clients. We offer Pressure Vessels in different designs as specified by the clients. Specification : Air Receivers up to 60 m 3 capacity Standard Accessories : Safety Vales Drain Valves Pressure gauges

Pressure Vessels

Get Price Quote

Pressure Vessels for the process industry . Vessels fabricated with 100% radiographic welding In house D.P testing , Hydraulic testing , Pnematic testing facilities available in house Radiography testing available inhouse All Jobs tested to 8kgcm2 as per ASME Standards

Pressure Vessels

Get Price Quote

Abhijeet Enterprises well facilitated infrastructural unit enables us to make a highly qualitative Pressure Vessel, which is developed by making use of excellent quality components. Features: Easy to use Quality tested Robust construction

Pressure Vessels

Get Price Quote

We manufacture and export optimum quality pressure vessels which are extensively used in chemical industries. We offer stainless steel pressure vessels, cylindrical pressure vessels etc. Which are made up of high quality raw materials. Pressure vessels are used to provide heat treatment to different liquids under fixed pressure. We use optimum quality steel in our vessel which make help them withstand heat and stress. We can even customize our pressure vessels according to the client requirements. We have also become one of the trustworthy pressure vessels exporters from india.

Pressure Vessels

Get Price Quote

Plastic Dies

Get Price Quote

As on of the leading manufacturers and suppliers of the industry, we are offering our clients the finest quality Plastic Dies. The offered dies are extensively used in the designing of automobile and electrical industry products. These dies are manufactured by making use of the best quality materials with the help of pioneering techniques under the observation of our dexterous team. In addition, these dies are stringently tested on certain parameters to meet the set industry standards. Features: Heat resistance Optimum strength Corrosion resistance

Gravity die casting

Get Price Quote

Height 2594mm(Approx.) Tilting +45,-45 Weight 5000kgs(Approx.) Die installation plate measurement 520 x 950 mm Hydraulic oil tank capacity 300 liters. Hydraulic power usage(daily) 50 kg cm2 Open Measurement 1035 mm Shut measurement 535 mm

aluminium pressure casting dies

Get Price Quote

We have come up as a dependable Manufacturer and Supplier of the best quality Aluminium Pressure Casting Dies. Aluminium Pressure Casting Dies are being manufactured using the best quality raw materials. We hold expertise in manufacturing all types of non-auto & Aluminium Pressure Casting Dies. Highlights : Superior performance Excellent material quality Exact precision Affordable price

Die Case

800 Per Piece

Die Cast Components

Get Price Quote

Casting weight - 93 kg, ANoy - Alsi7Mg (LM - 25),Job size : Dia - 800, Length - 800 mm, Special process involved - HMC Machining, Helium Leak Proof,Used in - Instrument Transformer

Die Cut Components

Get Price Quote

We offer Die Cut Components, which are useful for packaging of electrical devices, enclosures and a variety of other electrical applications. These Die Cut Components can also be customized as per the customers� packaging requirement. The Die Cut Components are precision-engineered for various applications. The Die Cut Components are available in various designs and dimensions for diverse applications.

Pressure Vessels

Get Price Quote

We are offering pressure vessels vessels is container & structural envelope in which materials are processed, treated or stored. pressure vessels are subject to various loading which exert stresses of different intensities in the vessel components. the category & intensity of stresses are the function of the nature of loadings, the geometry & constructions of the vessels components. A design pressure with 30 psi or 10% whichever is the greater will satisfy this requirement.

Pressure Vessels

Get Price Quote

We are offering pressure vessels . we provide highly acclaimed pressure vessels in the national and international market. The mild steel pressure vessels offered by us can withstand 40 kg hydro pressure while in the application. Our storage pressure vessels are fabricated from the best quality raw materials accessible in the market. The pressure vessels are thoroughly inspected at each and every stage during the manufacturing by our quality control engineers / third party or client inspectors before being handed over to the clients. Apart from that, we are one of the leading hydro pressure vessels manufacturers in india. applications used, where the gap between the two tube sheets is open to the atmosphere or provided with additional stub shells, so that any leakage should not result in mixing of shell side and tube side fluid. quality standards we supply pressure vessels, tanks, lpg storage tanks as per international codes like asme or as per customers’ requirements. material of construction carbon steel, low alloy steel, stainless steel, aluminium and copper.

aluminum alloy die castings

340 Per Kilogram

500 Kilogram (MOQ)

aluminium pressure die casting part

Get Price Quote

Aluminium Die Casting

Get Price Quote

Pressure Vessels

Get Price Quote

Pressure vessels can theoretically be almost any shape, but shapes made of sections of spheres, cylinders, and cones are usually employed. Detailed Description A common design is a cylinder with end caps called heads. Head shapes are frequently either hemispherical or dished (torispherical). More complicated shapes have historically been much harder to analyze for safe operation and are usually far more difficult to construct. Pressure vessels are used in a variety of applications in both industry and the private sector. They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks.

Pressure Vessels

Get Price Quote

Supplier & Manufacturer of Pressure Vessel & Shells for Pressure Vessel. Our product range also comprises of Fabrication, Tank and Base Frames. These Pressure Vessels are fabricated using superior grade basic material to ensure their compliance with defined industry standards.