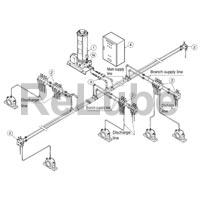

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. We are reckoned as one of the reputed Manufacturers and Suppliers of Dual Line Lubrication System. Manufactured under the strict vigilance of experts, our Lubrication System is known for its longer functional life. Tested using the latest techniques, our Lubrication System is free from all kinds of defects. Principle of operation : Two parallel lines run from pump to control valves and from control valves to metering devices and then to bearing points. End of line pressure switch gives signal to change over the line and thus continuous operation is ensured. Construction & operationA single outlet pump, 4/2 way direction control valve, metering devices, end of line pressure switches etc. are important parts of the system. In this system, lubricant is supplied from central pump to control valve, which further supplies it to the main lines and ultimately to bearings. When pump os started, one of the main line gets charged, it delivers required quantity of lubricant to bearings and at that time other main line acts as a relief line. When end if line pressure switch sends signal to changeover the line (i.e. half of the total number of lubrication points are covered.) After getting signal from end of line pressure switch, the changeover valve operates and the other main line gets charged and remaining half number of lubrication points gets lubricated. This ensures one complete cycle. Advantages of this system is that the pump used is high volume, high pressure type and number of bearings can be centralised is large (up to 1000 points). Applications Sugarcane Crushing Mills, Steel Rolling Mills, Metal Processing Machines, Power Plant Conveyers and Grate Coolers.

Dual Line Lubrication System

Get Price Quote

Lubcon Engineers are typically used in applications where a large number of lubrication points need to be lubricated from a single source. Each central lubricating unit is connected to their distributors through two lines via the change over valves. The two (2) lines alternatively act as supply pressure line and return line connected to container. When the central lubricating pump unit is operated, lubricant is delivered through the main lines of the system. The pump unit will continue to deliver lubricant and the pressure will continue to rise in the main line until the lubricant flow resistance at the lubrication point are overcome. At this point, the control valve and operating pistons within the individual metering distributors are actuated and a measured quantity of grease as determined by the diameter and length of stroke of the operating piston is delivered to the bearings. When all the metering distributors have discharged their respective quantities of lubricant, further pumping raises the line pressure. As soon as the line pressure exceeds the setting of pressure control valve, the change over valve operates to switch relieved to the grease container and the other line which was under relief is connected to the pump outlet so that next cycle of lubrication can start. The line pressure is sensed at the pump end and the pressure in the pressure control valve is set to a sufficiently high value in order to ensure operation of all the meter distributors. Both lines are blocked at the ends. There is a provision of visual indicator pins to the change over valve which is co-operation with a limit switch relays electric signal to the control system which deenergises the pump motor and activates the time relay which determines the interval time between two successive pumpings. After the pre-set time (0-2 hours) of the internal time relay is over, the pump re-stars and completes the next pumping cycle. The pumping repeats itself in the above manner and the lubrication of all points connected to the system continues.

Best Deals from Centralised Lubrication Systems

lube oil system

Get Price Quote

To cater this need CEE DEE VACUUM provides a solution with supplying oil storage tanks. There are different types of these tanks. The tank and capacity can be designed to suit the application and are available in the following categories: Mobile (Capacity range 1KL - 35KL), With Insulation, Without Insulation.

Air-Oil Lubrication System

Get Price Quote

In this system minimum quantity of oil is pushed by air in a narrow spiral tube and the tube is connected to the part of machine to be lubricated. The component of the machine / bearing is continuously supplied with droplet of oil. The air caries the oil droplet to the bearings & very small quantity of oil is supplied to bearings by using Lubomatic air-oil lubrication system the quantity of oil is precisely controlled. By using Lubomatic Air-Oil Lubrication system the machine can be operated at higher speed and productivity can be increased. The dust & dirt near by the bearings is forced away from the bearings and the bearing is kept clean & cool and lubricated. The air oil Lubrication is used in Grinding Machine Spindle Bearings Lubrication. Gear box lubrication of any machine. Rolling Mill bearing lubrication. Internal Grinding machine Bearing. Machine Slides Gear Train Conveyor chains ADVANTAGES The oil consumption is reduced considerably, compared to Oil-Mist lubrication. Reduced temperature of the bearings and the machine can be run at higher speed& inturn increase in the production. Due to continuous supply of fresh oil & air in right quantity. The bearings are protected from out side contamination & only minimum quantity of oil consumed. No mist in shop floor to breathe but only clean air.

Dual Line Lubrication System

450,000 Per unit

centralised lubrication systems

Get Price Quote

1 Set (MOQ)

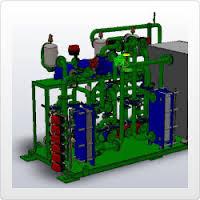

Forced Oil Lubrication System

Get Price Quote

TURBINE LUBE OIL SYSTEM

Get Price Quote

TURBINE LUBE OIL SYSTEM, Grit Blasting Unit

centralised oil lubrication system

Get Price Quote

centralised oil lubrication system, Grease, Lubricant Oil, O Rings

Lube Oil Systems

Get Price Quote

Lube Oil Systems, fuel gas handling system, offshore gas handling system

Lube Oil Filtration System

Get Price Quote

Lube Oil Filtration System, Industrial Bucket Simplex Filters

lube oil system

Get Price Quote

Metapow - We take pleasure in introducing ourselves as a renowned manufacturer and supplier of a wide variety of lube oil system in India.

Forced Oil Lubrication System

Get Price Quote

Forced Oil Lubrication System, overhauling services, Lubrication system

Centralised Automated Lubrication System for Construction

Get Price Quote

Centralised Automated Lubrication System for Construction

Oil Air Lubrication System

Get Price Quote

Oil Air Lubrication System, Single Line Lubrication Pump Unit, Ball Valves

centralised lubrication system

Get Price Quote

centralised lubrication system, crankshaft precision machine tools