wire wound fin tubes

Integral Fin Tubes : Max 19 finsinch, 26 finsinch. Tube Size : 38”, ½”, 58”, 34”, 1” Outer Diameters, Max Length : 6 meter, Material : C.S., Copper, S.S.304316, Cupro-Nickel, Brass.

...more

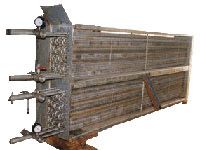

Water Cooled Heat Exchangers

• Air Compressor Coolers • Gear Box Oil Coolers • Hydraulic Power Pack Oil Coolers • Intercoolers • Aftercoolers • Chillers • Condensers

...more

Water Cooled Heat Exchanger

• Air Compressor Coolers • Gear Box Oil Coolers • Hydraulic Power Pack Oil Coolers • Intercoolers • Aftercoolers • Chillers • Condensers

...more

water cooled condenser

Air Compressors Coolers, Gear Box Oil Cooler, Hydraulic Power Pack Oil Coolers , Intercoolers, Aftercoolers, Chillers, Condensers.

...more

Refrigerator Compressor

Internal gear pump is provided with special self aligning driving plate to reduce vibrations to compressor and ensure trouble free long life of oil pump.Bearing surfaces of the high quality nodular cast iron crankshaft are ground to fine tolerances.Main bearings are white metal lined steel backed bushes, pressed into the cast iron bearing covers. Intermediate bearing blocks are provided with split type bearing shell of the same type. Each crankshaft is dynamically balanced together with the counter weightsForced Lubrication by an Internal Gear pump directly driven by the Crankshaft. The Pump incorporates two differential pressure regulators to provide separate pressures for two oil systems : Lubrication system and control oil system for operating cylinder loading unloading mechanism. Automatically operating solenoid valve ensures complete unloaded start of compressor. A Metal gauze suction filter element and a throwaway discharge paper filter cartridges are provided for excellent filtering capacity of the lubricating oil.

...more

Oil Coolers

Heavy duty radiators for industrial engines used in compressors (200 CFM to 900 CFM), Cranes, Bulldozers, Dumpers, Diesel Generating Sets (5 HP to 1000HP), Loaders, Excavators of reputed organisations like Kirloskar Pneumatics, Indian Railways, Defense Units, Refineries, Automobile, Chemical Plants, Sugar Factories etc.

...more

Oil Cooler Radiator

Heavy Duty Radiators for industrial engines used in compressors ( 200 CFM to 900 CFM ), Cranes, Bulldozers, Dumpers, Diesel Generating Sets ( 5 HP to 1000HP ), Loaders, Excavators of reputed organisations like Kirloskar Pneumatics, Indian Railways, Defense Units, Refineries, Automobile, Chemical Plants, Sugar Factories etc..

...more

intercoolers

Intercoolers Retaining foods freshness and value can be achieved by cooling and conditioning air inside cold room. This can be done by releasing excess heat to ambient air outside. It's all thank to air heat exchanger by Chintamani Thermal Technologies Pvt. Ltd. which are capable of capturing, and dissipating heat with right efficiency to surrounding.

...more

Finned Tube

Material : C.S., G.I., Copper, S.S.304/316, Cupro-Nickel, Brass.

Evaporative Condensers

Design Parameter • Condensing temperature 40°c for Ammonia wet bulb temperature 26°c * • We can design for any capacity, rating as per customers requirement. Technical Specification • Body constructed with G .1. Sheet and hot deep galvanising structure. • Condenser unit complete with SS-304, with 025.4,019.05. Tube • Airfans - axial flow fan, motor with IP - 55 insulation. Salient Features • Compact Design, Space Saving • Chocking Free Spray Nozzle • Design Base - HTRI Application • Dairy • Brewery • Chilling Plants • Cold Storage • Food Processing Industry • Industrial refrigeration where ammonia is used as refrigerant. Advantages • Substantial energy saving as compare PHE & Cooling Tower. • Substantial saving in space, piping as compared to PHE & Cooling Tower.

...more

elliptical tube

Max 16 finsinch, Tube Size : 38”, 12", 58”, 34" & 1", 1.25” Outer Dia, Max Length : 6 meters, Material : S.S.304316, Material : C.S., Copper, S.S.304316, Cupro-Nickel, Brass.

...more

Copper Finned Tubes

Straight Fins : Max 12 finsinch, Tube Size : 38”, 12", 58”, 34" & 1", 1.25” Outer Dia, Max Length : 6 Meters, Material : C.S., Copper, S.S.304316, Cupro-Nickel, Brass.

...more

Cooling Coils

Air Coolers for Air / Gas Cooling Aftercoolers for Oxygen Plant Intercoolers for Oxygen Plant Industrial Radiators Air Compressors Earth Moving Equipments Alternators Engines D.G. Sets Air Compressors Earth Moving Equipments Thermic Fluid Air Heaters, Rectifier Air Coolers Air Coolers for Railway Brake Compressors Intercoolers Aftercoolers “U” Tube Type Coolers

...more

Auto Radiator

Heavy Duty Radiators for Industrial Engines used in Compressors, Cranes, Bulldozers, Dumpers, Diesel Generating Sets ( 5 HP to 1000HP ), Loaders, Excavators of reputed organisations like Kirloskar Pneumatics, Indian Railways, Defense Units, Refineries, Automobile, Chemical Plants, Sugar Factories etc..

...more

Air Fin Coolers

Air Coolers for heavy duty motors, generators, turbo chargers, of different fin designs (e.g. Crimped fin, L-based, G-fin and wire wound fin). Air heaters ranging up to 375ºC, for textile and petrochemical units.

...more

Air Coolers And Air Heaters

Air Coolers for heavy duty motors, generators, turbo chargers, of different fin designs (e.g. Crimped fin, L-based, G-fin and wire wound fin). Air heaters ranging up to 375ºC, for textile and petrochemical units.

...more

Air Cooled Heat Exchangers

manufacturers and designers of air cooled heat exchanger using various finned tubes with different material of constructions like copper, s.s. 304 316, c.s., m.s., brass, cupro-nickel, aluminium etc.

...more

Heavy Duty Refrigeration Compressors

Salient Features Of Construction 1. Welded Steel Crankcase Less in weight, gas tight and impact proof smooth internal surfaces guarantees good oil condition. 2. Water cooled cylinder block The crankcase has in built water cooling jacket to avoid over heating of piston and liner element leading to trouble free long life of the compressor 3. Lubrication system and filter Crankshaft driven gear pump provides forced fed lubrication. The Pump incorporates a differential pressure regulator to provide separate pressures for two oil systems: lubrication system and control oil system. Automatically operating hydraulic delay valve ensures complete unloaded start of the compressor results in lesser starting current. A metal gauze suction filter element and magnetic filter are provided for excellent filtering capacity of the lubricating oil. 4. Crankshaft and main Bearings Bearing surfaces of the high quality nodular cast iron crankshaft are ground to fine tolerances. Main bearings are white metal lined with steel backed bushes, pressed into the cast iron bearing covers. An intermediate bearing block is provided with split type bearing shell of the same type. Each crankshaft is dynamically balanced together with the counter weights 5. Piston and Connecting Rod Assembly Compression and scrapper rings on the aluminum piston provided perfect sealing and low oil consumption. The nodular iron connecting rod is drilled through for pressure lubrication of the piston pin. Steel backed white metal shells on big end and bronze bearing on small end of connecting rod. The complete assembly can be removed from the top for servicing without withdrawing the cylinder liner 6. Cylinder Liner and Suction Valve Interchangeable cylinder liners are made of fine grained, centrifugally cast, alloy iron. Fine boring and honing results in a mirror smooth running surface. A hydraulic mechanical suction valve lifting mechanism on each individual cylinder achieves efficient and quick loading and unloading. For unloading, the suction valve ring is lifted from its seat in the cylinder collar by spring tension. Admitting controlled oil pressure to the control piston, allowing the suction valve ring to descend on its seat effects loading or cylinder. 7. Discharge Valve Assembly Three concentric discharge valve rings ensure ample gas passage at low lifting height. The use of sinusoidal springs together with precision machined and lapped surface results in a trouble-free operation for a remarkably long time. Minimum inventory for spares since most parts are identical throughout the CH series compressors. OPERATIONAL CHARECTERISTICS 1. Quick Maintenance : Parts subjected to wear are easily accessible through large service doors with minimum special tools 2. Easy Cleaning : Suction gas strainer inside gauze strainer element can be easily removed and cleaned within no time. 3. Easy Maintenance : Piston/connecting rod assembly can be removed without removing the cylinder liner. 4. Minimum oil Consumption : I s ensured by providing compression rings & oil scraper rings per piston - thus minimizing oil through discharge gas line 5. Safety: I s ensured by built-in arrangement of buffer spring which protects compressor from incidental liquid hammer 6. Extra Safety : Is ensured by built-in sight glass, making oil return flow visible hence avoids dry run of compressor and protect bearing wear and tear 7. Trouble-Free Long Running Life : This is possible due to highly effective oil purification by two filters. CH SERIES COMPRESSORS are : 1. Designed to operate with Ammonia, R22 & other HFC refrigerants.2. Ideally suitable for continuous duty, process refrigeration liquefaction plants, ice plants, cold storages, etc.3. Most suitable for industrial refrigeration and low temperature applications Accessories : 1. V-belt Drive 2. Base Frame for Compressor3. Oil Separator 4. Shut-off Valves5. Gauge/Cutout Board Assembly 6. Crankcase Heater

...more

Single Stage Refrigeration Compressors

Two Stage Refrigeration Compressors

Refrigeration Compressors

welded steel crankcase : low in weight gas tight and impact proof smooth internal surfaces guarantee good oil condition, bearing surfaces of the high quality nodular cast iron crankshaft are ground to fine tolerances.main bearings are white metal lined steel backed bushes, pressed into the cast iron bearing covers. Intermediate bearing blocks are provided with split type bearing shell of the same type. Each crankshaft is dynamically balanced together with the counter weights, interchangeable cylinder liners are made of finegrained, centrifugally cast, alloy iron. Fine boring and honing results in a mirror smooth running surface. A hydraulic mechanical suction valve lifting mechanism on each individual cylinder achieves loading and unloading. For unloading, the suction valve ring is lifted from its seat in the cylinder collar by spring tension. Admitting controlled oil pressure to the control piston, allowing the suction valve ring to descend on its seat effects loading or cylinder. 8. Discharge valve assembly : three concentric discharge valve rings ensure ample gas passage at low lifting height. The use of sinusoidal springs together with precision machined and lapped surface results in a trouble-free operation for a remarkably long time. Minimum inventory for spares since most parts are identical throughout the ch series compressors.

...moreBe first to Rate

Rate ThisOpening Hours