Jetcleaner Classic Tube Kit

Get Price Quote

pcb cleaning machine

1,500,000 - 2,500,000 Per Piece

Best Deals from Cleaning Machine

Clean In Place System

Get Price Quote

Buyers can acquire precision-engineered array of Clean In Place System at moderate prices, from us! We are reckoned for making available top-notch Systems in different technical specifications. Only quality tested raw material and modern manufacturing techniques are used for their production. In addition to this, we test them on the counts of performance and quality in order to deliver zero-defect product.

Floor Boring Machine

5,000,000 Per UNIT

Sand Screening Machines

Get Price Quote

This is a small and compact unit capable of output capacity up to 2 cubic meters per hour. Its small size and efficient operation make it a must-have on every site. This unit is available in both manual and electrical operation. Specifications for the machine is are mentioned below. Power – Manually Operated 1 H.P. Single Phase Electrical Motor. Mesh – 1” X 1” Supporting Mesh + Replacable 5mm X 5mm GI Mesh.

SACK SWEEPER

Get Price Quote

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

Aqueous Cleaning System

250,000 Per Units

Toilet Cleaner

Get Price Quote

Thakkar Plastic is engaged in offering Toilet Cleaner. The offered cleaner is processed under hygienic conditions and is characterized by precise chemical composition. Its advanced formula effectively eliminates stains, germs and yellowness. It is widely used in homes, hotels and offices. Features: Kills germs Leaves excellent shine Mild fragrance

Crank Shaft Cabinet Cleaning Machine

Get Price Quote

We are engaged in offering aqueous based industrial component cleaning machines industrial washing machines for high precision cleaning applications. These are crank shaft cabinet cleaning machine offered with advanced filtration & oil removal coalescing systems. Fabricated by our team of expert professionals, our range of component cleaning machines industrial washing machines is known to provide high precision cleaning to meet stringent millipore requirements and requires no manual intervention for loading and unloading of the stage components. major advantages & salient features: high precision cleaning to meet stringent millipore requirement stainless steel construction cost effective solutions meet production rate in time

Cylinder Head Conveyorised Cleaning Machine

500,000 Per Piece

Storage Tanks

Get Price Quote

We are among the leading Storage Tanks Manufacturers and Exporters. To satisfy your storage and feeding requirements, we have crafted three different types of tanks viz Holding tanks(round / conical), Balance tanks and Blending tanks. Our myriad of Storage tanks is synonymous to strength and durability.

TRACTOR ROAD SWEEPER MACHINE

Get Price Quote

Road sweeper machine Manufactured by Shrikrishna Agro Equipment pvt ltd is unique sweeper for road cleaning particular for rough road. It is most effective sweeping machine used to clean roads, Highways, internal roads and open spaces, Industrial premises. Road sweeping machine is designed for use with almost any tractor which is fitted with hydraulic lift; three point linkage and power take off and can be fitted or detached in less than five minutes.

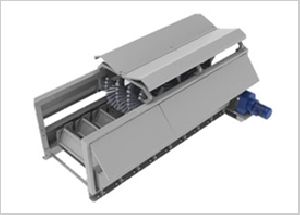

SACK SWEEPER

Get Price Quote

Cleans the sack from bottom, sides and top Installed at the sack discharge end of Rotary Packer. Recovers the spillage and dust on the sack Keeps the packing area clean Improves the working environment Uses the draught of the packer No extra air used Single drive in the form of geared motor The main module has pedestals at inlet and outlet which can be adjusted to match with the upstream and downstream of the equipment. This ensures smooth movement of the bags during transfers. The bed of the sack sweeper is made of powered rollers. The hollow rollers are fitted with brush that rotates in the opposite direction to make the brushing effective. The top brushes are also powered and fitted with bristles that can clean the sacks from top and sides. The level of the top brush can be adjusted to compensate the reduced length of the brush when it wears off. Safety covers are fitted on both sides. These covers are loaded with gas springs for ease of opening and closing. The drive is in the form of cascaded chains and sprockets – powered by a geared motor. The drive can be located on either side of the sack sweeper. The rpm of the geared motor can be chosen to suit the packer throughput. Top bonnet can be opened and closed with ease with the help of gas springs. Emergency stop push buttons are provided in all the four corners of the sweeper module

Web Cleaning System

Get Price Quote

We offer Web Cleaning System, the xstream non-contact web and sheet cleaner adopts a revolutionary approach to improve quality, reduce down time and boost profitability. It combines the latest aerodynamic nozzle technology with a defined high speed vacuum airflow and substrate ionization prior to cleaning within one turnkey system. the development of this system is based on technology used in aviation and aerospace research where, through the use of specially shaped edges and profiles, the air is forced in a certain direction at extremely high velocity. Hildebrand technology ag uses this technology and has developed its xstream surface cleaner based on this sound scientific knowledge. The xstream accommodates splices automatically and is available for use on web widths from 50mm up to 10 meters in either a single or a dual side surface cleaning configuration. The compact design minimizes the space requirements for installation. Our experienced application engineers can evaluate your machine and propose a solution for the implementation of xstream into your production process. technology: the special aerodynamic nozzle of the xstream which is positioned close to the surface of the substrate generates, through the combination of vacuum in the cleaning module and web speed, an extremely high velocity air flow (>60ms). The high velocity air flows along the substrate surface to the nozzle edge and into the cleaning module. The high velocity airflow breaks the boundary layer on the substrate and forces the particles that were trapped in this layer into the cleaning module. From the cleaning module the particles are transported to a filter unit. We are among the trusted Exporters and Suppliers of Web Cleaning System in India.

Walk Behind Floor Sweeper

45,000 Per Piece

steam khoya machine

95,450 - 755,450 Per UNIT

1 unit (MOQ)

180ltr steam khaoya making machine with motor an gear box tilting portable plant

Industrial Parts Cleaning Machines

Get Price Quote

Industrial Parts Cleaning Machines

Oil Cleaning System

Get Price Quote

Due to the Wire Drawing Process generates very high amount of metal sludge, leads to following problems: Increased Viscosity of Oil and hence Reduced Die Life. Choking of oil Passages. Poor Surface Finish of Wire. Increased Power Consumption. Increased Oil Temperature. High Viscosity Oil Sticks to the Wire being drawn, Increasing Oil Losses. Reduced Oil Life (Requiring Frequent Replacement). Increased Wear & Tear of Pumps.

Microwave Filters Cleaning Systems

Get Price Quote

HMI Rupas Upholstery Carpet Cleaner

Get Price Quote

Low foaming preparation for machine cleaning of moquettes, carpets, upholstery, textile, and leather Carpet shampoo, upholstery & leather cleaner with deep fiber cleaning effect. shampoo for all color fast and water-resistant carpets & upholstery furniture. Gentle on carpet HMI Rupas clean deeply, it has excellent foaming features, protects against resoiling & leaves pleasant aroma. cleans & refresh tissues without damaging them protects the clours, does not contain whitening or bleaching substances. Leaves a stable & fresh aroma Area of Application : Cleaning and refreshing of fabrics without harming, preserving the colors. Thanks to its unique formulation, HMI® Rupas L easily removes the contamination, penetrating deeply in the fabrics. Free of brightening and bleaching components. Leaves lasting and fresh aroma. HMI® Rupas L is particularly designed for use through the extraction method of cleaning or by a single disk machine. Dosage - 75–200 ml per 10 L of water, depending on the extent of contamination.