Air Diffuser

900 Per Piece

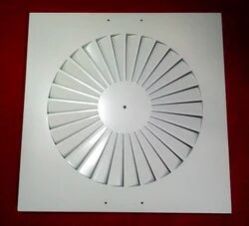

Swirl Diffusers

1,550 Per Piece

50 Piece (MOQ)

Best Deals from Commercial Air Conditioner

Panel Type Pre Filter

10,000 Per Piece

Milk Chiller

Get Price Quote

We offer Milk chiller to keep the temperature of milk to 4 °C. Chiller is a machine that removes heat from a liquid. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. As a necessary byproduct, refrigeration creates waste heat that must be exhausted to ambient or, for greater efficiency, recovered for heating purposes. Concerns in design and selection of chillers include performance, efficiency, maintenance and product life cycle environmental impact.

PES Pleated Filter Cartridges

4,000 Per Piece

1 Piece (MOQ)

polycarbonate louvers

Get Price Quote

Features Louvers play an important role in ensuring effective ventilation of a building. Wind-driven ventilators or exhaust fans suck out of air from within the building or shed. This causes a drop in pressure within the building. Louvers provide the vents from which fresh air can enter the system and provide effective circulation of air In the absence of louvers, there would be a drastic drop in the efficiency of ventilators of exhaust fans Polycarbonate Louvers are available in matching profile with all conventional industrial roofing profiles to ensure ease of installation along with vertical cladding sheets They ensure proper circulation Provide daylight thereby reducing power consumption for lighting during day time They are durable virtually unbreakable and weather resistant, natural light during day time, thus reducing lighting load They are resistant to high temperature and last long Polycarbonate louvers are available in profile and width matching to conventional industrial profiled sheets used for cladding. These louvers are available in standard length of 1.7 m The Louvers are made from 2 mm thick Polycarbonate embossed sheets

Water Cooled Chilling Plant

Get Price Quote

We are one of the leading manufacturers and suppliers of Water Cooled Chilling Plant based in Pune, Maharashtra. These plants are used in various industries where water needs to be cooled down using a closed loop system. The chilling plants that we offer are constructed and manufactured to be sturdy and strong and have little or no flaws. The plants can be easily installed and maintained. Features :- Sturdy construction Superior quality Easy to install & Maintain

900x450mm C250 Ton Frp cover with frame

10,500 - 11,840 Per Nos

20 Nos (MOQ)

Circular Diffusers

650 Per Each

100 pieces (MOQ)

Circular Diffusers, linear grills, square diffusers, slot diffusers

Butterfly Dampers

150,000,000 Per Piece

We are the main supplier of this product.

Duct Damper

Get Price Quote

Control Valve

Get Price Quote

2 Piece(s) (MOQ)

•streamlined flow passage •improved flow characteristics •easy modification in capacity and trim design pressure rating •ansi #150 •ansi #300 •ansi #600 •ansi #900 body material •cast carbon steel a216 wcb upto temp. 427° c •cast alloy steel a217wc6wc9 above temp. 427° c •stainless steel a351 cf8cf8m for corrosive medium •other body materials on request! trim material •ss 410420 for steam, air, oil •ss 304316 for corrosive medium •stellited trim for erosive medium •other body materials on request!

Industrial Dampers

Get Price Quote

Heavy-duty design that is suitable for applications with clean, corrosive, dirty, andor dry environments. Manufactured in-house under strict quality control procedures. IFI’s range of butterfly dampers are best suited in Duct and Ventilation system where flow control and balancing is required.

Panel Air Conditioner

Get Price Quote

EPDM Diffuser

Get Price Quote

milk chilling plants

100,000 Per Piece

Air Handling Units

Get Price Quote

Construction Available in different capacities, the Modular Air Handling Units (AHU) manufactured by Consultech offer the best results with minimum hassle. Having been in the industry for two decades, Consultech offers a blend of traditional functionality with modern methodology to meet the ever-changing requirements of the industry. The strong framework design of AHUs offers inherent strength and stability. The aluminum profiles are corrosion resistant with specially designed three way corners. The panels are pressure injected with CFC free polyurethane foam up to 40 Kg/cum densities. A galvanized steel channel base is used to mount the entire framework. The condensate drain pan is fabricated out of corrosion resistant stainless steel insulated on outside with close cell insulation. The compact allows the units to be vibration-free which enable noiseless performance. The former makes the units easily maintainable. Sections with imported centrifugal fan, cooling coil, and filters comprise of the basic assembly. We also provide add-on optional modules such as thermal break with coved profiles, heating coil, face and pass damper, humidifiers and air mixing chambers are also available on specific demand. The units can be manufactured with direct drive plug fans as well. The units are available in Single Skin , Double Skin, Ceiling Suspended type. Selection When the capacity, size and other specifications are in accordance with the work to be performed that is when the highest efficiency in an Air Handling System is always attained. The following factors are important while selecting the most appropriate Air Handling Unit for a specific application.

Coolant Filtration System For Aluminium Machining

Get Price Quote

Aluminium is vastly used in automobile components. Various operations like drilling tapping on such components generate large quantum of chips. Individual filtration system are prone to breakdowns and do not give required filtration levels resulting in low coolant life.In a CFS, Dirty fluid along with chips is collected in the dirty tank. This tank has a continuously moving scarper conveyor which removes the chips that settle down. A rotating mesh drum is placed inside this tank. The fluid passes through the mesh drum while the chips are separated on the outside. The filtered fluid drops into a clean tank. Clean fluid pump supply pressurized fluid to the machines. Sizing of the tanks, mesh drum and pumps is done based on your total flow requirement. In addition fine filter housing can be provided for through spindle coolant. Features & Benefits Large dirty tank gives sufficient time for the chips to settle. It also improves heat dissipation. Single point chip collection. Independently rotating mesh drum with inward and outward flushing nozzle. Multiple drums for larger systems. Drums can be isolated individually. Our unique seal design reduces the seal size. Multi paneled drum for ease of mesh maintenance. Built in PLC Controlled electrical and mechanical safety with Auto conveyor Jamming logic. Skimmers, Week end agitation, VFD can be added with further enhance the system. Customized design to suit your specific requirement. Components Mesh Upflow Drum Filter Scraper Conveyor

ENGINE COOLANT CONDITIONING SYSTEM

Get Price Quote

The system essentially comprises: Heat Exchanger Motorized Valve Circulation Pump with VFD Drain Pump SS In-cell Tank with level switch & level gauge Filters at inlet of the tank, inlet of the engine and in the drain circuits Heater Temperature Control for Heater & engine water out temperature with sensors Ball Valves, NRVs, pressure gauges, piping, etc. Here, the raw water is used for controlled heat removal from the engine so as to maintain coolant outlet temperature say at 85o C. (settable range 80 oC ~ 95 oC) Initial heating of coolant at 70 oC with auto timer so that engine is filled with hot coolant; insulated, hot water storage tank with level control, visual glass tube level indicator, over flow and drain, auto & manual filling provision. Following Auto functions are provided: Engine filling, External pump to assist engines own pump. Drain, Blow-down with compressed air

Air Handling Unit

200,000 Per Piece

01 Piece (MOQ)