wall putty spray machine Surya 10

180,000 Per Nos

1 Piece (MOQ)

Hydraulic Concrete Block Making Machine (H600)

Get Price Quote

Buyers can get in touch with us to buy Hydraulic Concrete Block Making Machine (H600) that is extensively used for making blocks required for construction purposes. Reckoned for sturdy construction, uninterrupted performance and long life, our Hydraulic Concrete Block Making Machines are cost-effective. The Hydraulic Concrete Block Making Machines can be purchased in bulk from us.

Best Deals from Construction Equipment

Table Vibrator

Get Price Quote

1 Piece (MOQ)

Macadamia Grafted Original plant

2,500 - 3,500 Per piece

10 Piece (MOQ)

Concrete Block Making Machine

100,000 - 500,000 Per Piece

1 Piece (MOQ)

PLC, DCS, HMI & SCADA BASED CONTROL SYSTEMS FOR WATER CONTROL MANAGEMENT TRUNKEY PROJECTS (Installation & Commissioning Services) CONCRETE BLOCK MAKING MACHINE AUTOMATION SYSTEM INSTALLATION, COMMISSIONING & TESTING SERVICE PROVIDER Details: Logic development for the SPM used for concrete block making Logic development for Batching Plant used to prepare concrete mixture for block making machine. Auto weighing, tarring, water mixing& block making. Recipe management for different batches for different quality/quantity production. Auto report generation & monitoring from remote place for indusial batch, day wise, week wise, monthly Production

Solid Carbide End Milling Cutter

Get Price Quote

1 Piece (MOQ)

screed plate

38,000 Per Set

1 Set (MOQ)

Construction Bucket

Get Price Quote

1000 Piece (MOQ)

Epoxy Mixing Cum Casting Plant

90,000 Per Piece

1 Piece (MOQ)

epoxy mixing plant

Get Price Quote

Fly Ash & Cement Silo

11,000 - 21,000 Per Nos

1 Piece (MOQ)

sahyadri engineering has started a production of cement /flyash /microsilica silo with silo capacity ranges from 5mt to 200mt. sahyadri engineering efficiency in producing quality products have dramatically increased the commercial value of these products. silos can contain varying capacities of powder materials and are processed using state of the art technology. the use of silos mainly lies in storing and discharging construction materials such as cement, flyash, ggbs, lime, etc. some silos can hold comparatively lower measurements and therefore, can be taken from place to place for their capacity to move. the silos are layered with primer coating and final coating as per customer’s requirements. the silo is painted in specially made painting cabinets. only after all this procedure can a silo be packed for transportation to the destined construction site. cement silos have huge leg-stands to hold the weight of the heavy loads. ladders and upper parapets are used to reach the topmost sections. a silo has a valve in the discharging section that can be either controlled manually or automatically giving the process a well determined flexibility.

Caterpillar Mini Hydraulic Excavator

Get Price Quote

1 Piece (MOQ)

Concrete Cube Moulds

Get Price Quote

We are offering cube mould 150*150*150.

Vibrating table

20,000 - 75,000 Per Piece

1 Piece(s) (MOQ)

We offer Vibrating Table. Backed by experienced and expert team we are offering range of Vibrating Table

Stainless Steel Industrial Platform

Get Price Quote

Pan Connector

500 - 550 Per Piece

10 Piece (MOQ)

Epoxy Mixing & Casting Plants

Get Price Quote

In order to obtain void-free epoxy castings with low partial discharge and good du-electric strength suitable for use at high voltage it is necessary, among other things, to mix the resin & pre-dried filler well, to de-aerate it by vacuum and finally to pour it, also in vacuum. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Water-cooled trap is provided for preventing volatile hardeners from entering the vacuum pump. Pouring chamber can be heated or unheated as required. Rotary turntable with vacuum-tight rotary seal or chain & sprocket driven trolley or rails allows the moulds to be positioned below the pouring spout without breaking vacuum. Epoxy mixing & de-aerating plant: Medium size epoxy vacuum mixing plant for use in the laboratories of a progressive Electrical Manufacturer can handle from 5 kg to 200 kg of Resin-filler gardner mix. It is very versatile being able to handle solid or liquid resins hot or cold processing. Temperatures fro 160oC to room temperature are possible. A vacuum of 1 torr is easily obtained. the use of the plant enables void-free castings to be obtained. Our Team The reason behind the success and growth of our organization is the support of our competent team of experts. These professionals have industry expertise of many years and posses a thorough knowledge in their respective domains. We make sure that the professionals are regularly trained to keep them updated about the market scenario. The team consists of the following: Technicians Quality controllers Research & development associates Sales & marketing executives With the united and tenacious efforts of these professionals, we ensure that the products offered by us are in compliance with the needs of our clients.

grouting machines

600,000 - 1,500,000 Per Set

1 Set (MOQ)

UELZENER multi-functional worm pump system for: Repair Mortars, Gel Mortars, Stucco, Fireproofing coatings, EIFS, Pressure grout, Vermiculite, flowable and non-flowable grouts and Bentonite waterproofing grouts. Grouting machines are suitable ready-mix Grouts:Backfilling mortars / injection / joint filling grouts => Mixing+ Pumping+ Conveying+ Placing

Concrete Cutter

Get Price Quote

The new GS 461 concrete cutter combines all the new features of a STIHL chainsaw plus many new features that will make cutting concrete easier, quicker and with more comfort. The GS 461 is designed for free hand cutting in concrete with re-enforcing, natural stone, sewage pipes (concrete, ductile iron) and general masonry. The GS 461’s maneuverability makes it perfect for cutting in tight spots or close up against a 90 degree corner. Suited to the professional user, the GS 461 is ideal for rental outlets, landscape gardeners and fire and rescue services.

sand making machines

Get Price Quote

Our VSI Sand making Machine have an autogenous working principle Designed for tertiary and quaternary applications, they can handle anything From hard and abrasive rocks to soft, moist and even sticky materials. Used in quality aggregate production for concrete products, road construction And dam production, to mining industries used as pre-grinders to mills resulting in huge power saving. They give excellent product shape and are also ideal for Crushing minerals slag clinker and glass.

Sand Making Machines

Get Price Quote

Cellular Lightweight Concrete Moulds, Allied Fabrication Services

Mobile Concrete Batching Plants

Get Price Quote

We are a Manufacturer and Supplier of Mobile Concrete Batching Plants If there is a need of large amount of concrete on your site, then our Concrete Mobile Batching Plants is the best solution for you. This plant can create large batches of concrete for longer period at the site of construction. Our Mobile Concrete Batching Plant gives continuous supply of concrete without in stoppage to the workflow. Our Mobile Concrete Batching Plants are used in large workloads such as warehouses, wind farms, and civil engineering projects, which greatly benefit from an uninterrupted supply of concrete. The ability to produce more concrete on site when needed keeps things in succession efficiently, and helps in getting build completed proficiently.

Cement Silo

Get Price Quote

1 Piece (MOQ)

What is Cement Silo? The cement silo is one of the most important parts in the production line. It is a big machine that stores and mixes cement. Cement is used to produce concrete, which is then used in construction and other industries. Three Types of Cement Silos Wet, Dry, and submerged. Wet silos are the most common type found in new construction projects, while submerged silos are used in long-term storage applications. Silo work is difficult and can often present serious safety risks to the workers involved. Quality Tech Engineers - a cement silo manufacturers, Suppliers, Exporters in Pune,India,Maharashtra. who provides its service to the construction industry of India. They are a leading suppliers of cement silos in Pune and also have presence in other cities across India. Cement Silo, Manufacturers,Suppliers, Exporters in Pune:The Company started operations in the year 2010. The Cement Silo Operates on 3 Basic Functions : Supplies, Storage, and Mixing. The supply function involves taking raw materials and delivering it to the mixing process automatically with an electronic sensor monitoring the supply valve. In storage, it has an automatic system that monitors weight variation by using a quadratic equation to calculate how much material was stored and unloaded. Mixing takes place at pre-set temperatures with control of mixture speed through a programmed control system. We also provide a range of services which includes complete engineering solutions for filtration, water treatment, boiler feed water treatment Our product range includes Bag Filters of various capacities and material,Bag Filter System,Wet Scrubbers System,Acid Gas Scrubber System, Cement Silo,Centrifugal Blower,Centrifugal Fans,Dust Extraction System,Fume Extraction System,Multi Cyclone Dust Collector.

Grapes Farming Cover

220 - 250 Per kg

1 Piece (MOQ)

Sand Filter Plants

Get Price Quote

Solid Carbide Slitting Cutter

800 Per

10 Piece(s) (MOQ)

Adjustable Base Jack

Get Price Quote

Epoxy Pu Injection Grouting Machine

13,500 Per

5 Piece (MOQ)

We offer epoxy pu injection grouting pump ultrabest aadhar with hopper, two component injection grouting machine, bosch ve injection grouting machine, 01 bosch pu grouting machine, epoxy injection grouting machine and digital injection grouting machine from India.

Concrete brick making machine

Get Price Quote

In order to meet the diversified requirement of the customers, our organization is engaged in offering precision designedCLC (Cellular Lightweight Concrete) Brick Making Machine.Offered machine is widely used in various industries for making a variety of bricks of different size. In order to maintain the industry standards and to avoid any kind of flaw, this machine is stringently examined under the supervision of highly experienced quality controllers.

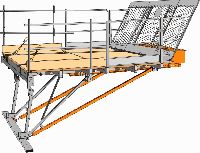

construction platform

Get Price Quote

SRP 500 SRP 800: Temporary suspended platforms are kind of aerial working platforms which can take the place of traditional scaffolding. The suspension mechanism can easily erect & shifted with two persons. Suspended access equipment is multipurpose & efficient machine to work at heights. External straight wall construction, plastering & painting, Aluminum Composite Panel & glass cladding, External plumbing fitting, electrical fitting & minor repairing maintenance work, Man & material, access to external works are sure to simplify & faster the construction, Shipbuilding for vessel repairing welding & maintenance work.