Plate Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

Our Plate Bending Machine comes in different capacities ranging from 1.5 meters to 3 meters and thickness ranging from 3mm to 100 mm. It comes with 3 and 4 rolls and single and double pinch. Further, Plate Bending Machine is equipped with independent motors and gearboxes, two powerful hydraulic cylinders, and a hydraulically operated drop end bearing. Plate Bending Machine has a sturdy construction, user-friendly operation, and low operational cost, because of which it is preferred by various manufacturers. Applications : Double Pinch Three Rolls plate bending machines are considered as the ideal solution to roll plates into cylinders with a minimum investment. They are known to be the best solution for rolling cones other than cylinders. How It Works : The pre-bending is made by positing the plate edge between the pinch rolls and by moving the bending roll with a pressing operation. After the first edge is pre-bent it is not necessary to remove it from the rolls as the second pre-bending can be made immediately following the same procedure used for the first edge. As soon as the two plate edges have been formed, it is possible to proceed with the rolling to distribute the deformation along the plate developed length. He Biko Three Rolls Technology : Ultra-Wide drop end : minimises the top roll transverse movement guaranteeing superior quality of the rolled product that will not be affected by excessive frame extension and torsion. Fully Hydraulic Movements : to provide maximum bending power without loss of energy and overloads on mechanicalcomponents; Hydraulic Circuit made with rigid steel pipes guarantee reliability and positioning precision. High Capacity roller and spherical bearings : provide friction-free rotational movement of rolls and reduce maintenance needs. Swing Arms friction is eliminated by areliable lubrication system guaranteeing long term reliability. Rolls Made of Certified Quality steel : with large shafts diameter minimise the deflection under load and damage on the surface. Upon request they can be induction hardened to over 50 HRC and surface polished. Direct Drive for rolls rotation : for high torque fast rolling power and maximum efficiency trough planetary gearboxes. All three rolls are driven independently. Automatic Rolls Peripheral Speed Compensation : to guarantee optimum distribution of the torque without need of manual adjustment. Clamping Pressure Control : for optimum automatic setting of the pinch roll position according to the different plate sizes. Mobile control console : positioned at the front of the machine is the ideal solution to keep under control the rolling process from the best point of view. Safety Barrier : for immediate emergency stop of machines movement when the operator is near hazardous area. Accessories On Demand : Top Support : It avoids the rolling of overlapped plate edges. It helps the positioning of the plate edges for tack welding. Dimensions : 3mt x 3Ton Digital Readouts : Two (2) Electronic digital displays mounted on the operator’s control indicate the positions of the left and right bending rolls. (X & Y axes.)Cone Rolling Package : Hydraulic tilting of the bending rolls. Hydraulic tilting of the bottom pinch roll. Cone stopper (friction or wheel typ. Accessories Included with the Machine : Prevents excessive roll wear especially when rolling cones or when rolling Stainless steel, flame out steel and other hard materials. Prevents scratching of the roll surfaces. CE Certification : For machine safety.Main Technical Data : Maximum Rolling Capacity (Cold) : mm. 20 Maximum Pre-bending Capacity (Cold) : mm. 15 Cone capacity by continuous rolling : 60% of prebending thickness Cone capacity by pressing : 100% of prebending thickness For further bending capacities, please refer to the detailed Capacity Chart. Rolls face length : mm. 3.050 Number of rolls : Three Diameter of Top Roll mm. 350 Diameter of Bottom Rolls mm. 320 Powered Driving Rolls : Three Drive System : Directly splined on the roll shaft Surface Speed Compensation Automatic Rolling speed : 5Mt./min. Rolls movements adjustment Hydraulic Installed power (Energy Saving Technology) ES HP 25 Power Supply 380 Volts, 3 Phase, 50 Cycle

Mobile Batching Plants

Get Price Quote

These Aquarius mobile batching plants directly discharge the concretein to the transit mixer. Overview The ultimate technology mobile plants, mounted on re-usable precast foundations. The foundations can be lifted and shifted to another location. MP series is available with 0.35 and 0.5 cubic meter compacted output planetary mixers & 1.0, 1.25 & 2 cubic meter twin shaft mixers Accommodates four types of aggregates, two types of cement, fly ash, two types of chemical additives, fresh water and recycled water. The compact design boosts the production capacity and fits in thin plot sizes. Available with two levels of control system with decent features built in for contractors and ready-mix manufacturers. Salient Features: Drive through design for increased productivity Mounted on re-usable precast foundations, which can be shifted to other locations easily Available with 0.35 & 0.5 cubic meter batch size Planetary Mixer and above 1 cubic meter Twin Shaft Mixer Deliver consistent quality concrete and are most preferred in the RMC industry Four Aggregate compartment Bins with a total storage capacity of 18/30/50/70 cubic meter High precision load cells for independent electronic weighing of cement, aggregates & water with digital display Two-level PLC based control system with real-time SCADA for control and data management, RT - MATIC PLUS / RT – SMART Compact design that boosts fits in confined spaces Low operation & maintenance cost Minimum aggregate loading height Robust structure with corrugated bins Large mixer platform for ease of maintenance Added safety with double wire rope for skip Control cabin included in standard scope AQUARIUS Mobile Plants directly discharge the concrete into a Transit Mixer. The plants are mounted on re-usable precast foundations, which can be shifted to another location easily. Available with 0.35m3 & 0.5m3 Planetary Mixer, 1m3 and 1.25m3 Twin Shaft Mixers, with an hourly production of 21m3, 30m3, 60m3, 70m3 and 90m3 per hour. The Mobile Plants are provided with four Aggregate Bins with a total storage capacity of 18/30/40/50/70 cubic meters. With high precision load cells for electronic weighing of cement, aggregates & water and a digital display, the MP series plants are the most compact mobile batching plants from AQUARIUS range of products.Another feature is the Skip Hoist arrangement for mixer loading and a modular, two-level PLC based control system with real-time SCADA for control and data management, RT-MATIC PLUS & RT-SMART. Plants have a compact design that boosts the production capacity and fits in smaller plot sizes.An Admixture Dosing Unit and a standard Cement Screw Conveyor are also a part of the standard offering. A highly minimized operation & maintenance cost and a possible continuous production cycle as low as __seconds make the MP Series Plants the most preferred plants in the Contractor & RMC segment. The MP 21 Plant is designed by understanding the requirements of the small sites which do not need concrete production rate as high as 30 m3 per hr but installation and shifting time required is minimum possible. Keeping most of the features of premium size plants like drive through design for transit mixer loading, belt weighing for aggregates, independent cement and water weighing systems, PLC and SCADA based control system…etc the new models are equipped with 0.35 m3 compacted output batch size for optimum usage of the equipment. Thanks to the compact design these plants fit in smaller plot size. Similar to their big brothers in this range, these plants also do not need any permanent foundations but only re-usable precast foundations for mixer structure and PCC for aggregate storage bins. The plants are provided with four compartments for the aggregate storage bins with a very low loading height. High precision load cells and electronic weighing systems ensure batching accuracies.PLC and PC based control system is another highlight in this range. SCADA based system with all possible data analysis, remote assistance, data in Excel format, consumption records, alarms and online help…etc make this plant nothing less than the high end plants.These plants are equipped with planetary mixers which is a unique feature in this range. Planetary mixers obviously ensure fast and homogeneous mixing in shortest possible time with very low operating costs in this size.

Best Deals from Construction Machine

Mobile Batching Plant

Get Price Quote

An innovative, customized concrete production solution for contractors.The plant requires absolutely no foundations but only PCC work. Standard model available with Planetary Mixer of 0.35 m3 compacted output per batch. Accommodates four types of aggregates, cement, fly ash, water and chemical additive. Plant has a unique design that reduces transport cost, crainage cost and shifting time drastically. State-of-art modular PLC based control system provided with HMI control. Download Catlogue - Super Mobile Batching Plants – SMP 21 Super Mobile Batching Plants – SMP 21 The concrete discharge is directly in the pump hopper. No expenditure against transit mixer purchases and their operation costs. Low connected load helps keeping your electricity costs lower. Very low operation and maintenance costs.A great way to go independent, as far as your concrete requirements are concerned. Key Features No foundation work required for the plant. Minimum of PCC work is sufficient for plant installation. Compact plant design with Incline weighing belt to ensure accurate weighing and reduced maintenance costs.

Batch Type Washing Machine

200,000 Per Piece

Channel Letter Bending Machine

Get Price Quote

Channel letters are made up of plastic or metal letter which are usually used for exterior signage in commercial and public buildings. These are usually in 3 dimensional graphic signs. These signs are made by cutting aluminum sheets or plastic sheets by the computer controlled router, laser or other jet based vector art file. The channel letter bending machine is used for cutting the material and bending it into the appropriate shape. Our machines are preferred by the clients because of their efficiency, perfect finish and accuracy in the bends. We have assigned a team of experts and professionals to inspect the quality and handle the whole manufacturing process and create a complete well specified machine. These machines are supplier in Ahmedabad, Gujarat as well as exported in Maharashtra and Andhra Pradesh. These machines are made using advanced and revolutionary technology in order to provide higher priority in performance and quick services. Features: Long service life Flexible operation Neat cutting Low maintenance Fast output Low thermal influence Smooth running

sand making machines

Get Price Quote

Our VSI Sand making Machine have an autogenous working principle Designed for tertiary and quaternary applications, they can handle anything From hard and abrasive rocks to soft, moist and even sticky materials. Used in quality aggregate production for concrete products, road construction And dam production, to mining industries used as pre-grinders to mills resulting in huge power saving. They give excellent product shape and are also ideal for Crushing minerals slag clinker and glass.

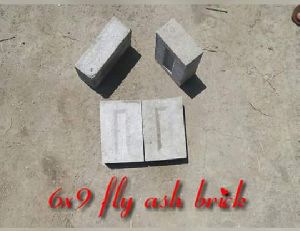

Fly Ash Brick Press Machine

6 Per

4x9 Fly Ash Bricks / Colour - Grey Material Use - Crush Sand / Cement / Fly Ash . Rate Ex - Factory + GST + Transport

Inkjet Batch Coding Machine

Get Price Quote

1 unit (MOQ)

work platform

94,000 - 95,000 Per Piece

Construction Equipment

Get Price Quote

GPS and GPRS based data acquisition system (Old version) Salient Features: Temperature and vibration status Global position Number of passed and speed OEM solution to L & T, Escorts etc.

Sand Making Unit

37,500,000 Per unit

1 unit (MOQ)

concrete hoist

Get Price Quote

Concrete Mixer This mixer also acts as a hoist and can transport the concrete up to 60ft high. Capacity - 107 HP. Power - 10HP Aircooled Diesel Engine. Lifting Height - Up to 60ft. Heavy Duty Drum with Bearing and MS blades. Loading Hopper - Mechanically operated wire rope type. cum Hoist

Cement Weigh Hopper

Get Price Quote

Cement Weigh hopper with Screw suitable for small plants or paving blocks & brick suppliers, Cement Weigh hopper with Screw suitable for small plants or paving blocks & brick suppliers

Concrete Mixer

Get Price Quote

RAB-250 UMI Hardness Testers, VM 50 Vickers Hardness Tester

Concrete batching Plants

Get Price Quote

The plants are designed for ready-mix producers, contractors, precast manufacturers and special applications. Standard models furnished with Twin Shaft Mixers from 1.0 m3 up to 6.0 m3 compacted output per batch.

Inkjet Batch Coding Machine

110,000 Per Piece

1 Piece(s) (MOQ)

Concrete Conveying Equipment

Get Price Quote

If plant capacity is sufficient to cater the various application this distribution & conveying system seems to be the best to utilized the plant to its full extent.

TRACTOR ROAD SWEEPER MACHINE

Get Price Quote

Road sweeper machine Manufactured by Shrikrishna Agro Equipment pvt ltd is unique sweeper for road cleaning particular for rough road. It is most effective sweeping machine used to clean roads, Highways, internal roads and open spaces, Industrial premises. Road sweeping machine is designed for use with almost any tractor which is fitted with hydraulic lift; three point linkage and power take off and can be fitted or detached in less than five minutes.

Cylinder block Bearing Machine

Get Price Quote

Washers

Get Price Quote

Using IS-2016 Grade A, En-8, En-19, SS-410, SS-304, SS-316 or any other material as per customer’s requirement. Surface Treatment : Blackodised, Phosphated, Zinc Plated with yellow, blue, olive green passivation. Threading Sizes M6 to M100 ISO, Metric 6g, as per IS-4218 or equivalent in BSW / UNC of following types As per IS-2016 Type A Punched Washers for Hex Bolts & Screws. As per IS 2016 Type B Punched Washers for Round & Cheese Head Screws. Any other Washers as per customer’s requirement.