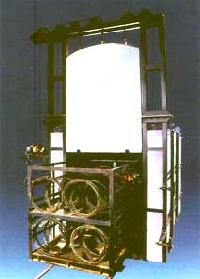

Continuous Normalizing Cum Hardening Furnace

2,500,000 Per ONE

Continuous Gas Carburising Furnaces

Get Price Quote

Continuous Gas Carburising Furnaces 1750°F (950°C) Fields of application (under protective gas) • Hardening • Carburizing • Carbonitriding Automatic production line with conveyor including : • Loading systems • Pre Washing machines • Preheating Furnace • Carburising furnace • Diffusion furnace • Hardening furnace • Quenching system • Post washing machine • Tempering furnace • Unloading bay The elements can be heated by Radiant tube type heaters (Electric or fuel fired). These continuous lines are used for carburizing, carbonitriding, tempering and hardening with quenching in oil, water, polymers or salt. Application - Carburising and hardening of Crown, Pinions, screws, bolts, ball-bearings, springs etc. The high degree of automation, quality of the materials and simple construction of the equipment guarantees a reliable and efficient production with high degree of economy resulting in profitable production.The elements of our installations can be easily integrated into already existing production lines. Advantages - • Gas-tight channel with preheating zone • The upper part of the furnace consists of several elements, which can be dismantled easily. • Dismantling of circulating fans and O2-probes from the top of the furnace • Heating elements or burners can be dismantled without complete standstill of the installation • Continuous, controlled drive of the conveyor • Easy access to all regulating elements • Regulation of the carbon potential for every single zone • Homogeneity and reproducibility of the treatments • SCADA system for up to date recording of the parameters • Quick change of the treatment cycles

Best Deals from Continuous Furnaces

Mesh Belt Continuous Furnace

500,000 Per Unit

Continuous Aluminum Brazing Furnace

Get Price Quote

Continuous Aluminum Brazing Furnace, Aluminum Brazing furnaces

Continuous Electrical Normalising furnace

Get Price Quote

Continuous Electrical Normalising furnace