Mild Steel Conveyor Idler Frame

Get Price Quote

50 Piece (MOQ)

Flat Belt Conveyors

Get Price Quote

Garud Automation range of hard wearing belt conveyors giving many years of reliability.Our aim is to build a lasting relationship with our clients and offer the complete package. Can we Help You?Garud Automation welcomes a challenge and offers our assistance with the development of your production processes.Each of our conveyors is engineered to handle your products carefully.Materials used to fabricate the frame are usually dictated by your industry we offer stainless steel, mild steel and aluminum; Belting is also variable and includes; PVC Polyurethane Silicon Resin PU Belt Teflon Plastic Belt / Modular Belt Felt Rubber Wire Belt Garud Automation are able to integrate our conveyors into existing machinery with the little disruption to normal production process. Industries we supply to include. Logistics & Transport Building & Construction Industrial Applications Conveyor Belts how versatile are they? Belt sizes start at approximately 100mm up to 1000mm as standard but we can offer much widerbelts for special applications.Side Guides can be added to restrict your products if desired. Elevating your materials on inclines or declines is achieved by fixing flights to the belt.The number of flights and what pitch will be dictated by the angle desired and your product. Speed can be varied by adding an inverter of mechanical variator and typically can run 2m/min to 50m/min defendant on product. For convenience of transporting your belt conveyor it can be made portable by adding casterswhen the legs are being fabricated. We are able to supply belt conveyors that will accommodate bends and corners. Bespoke Systems designed to carry tubes, Modular Belt Conveyor transporting packs of rice using plastic belt and gravity rollers. Magnetic Conveyor used to convey empty cans for a food factory into the processing areas for filling and packing. New product our Close Transfer Conveyor Tube Sorting Conveyor System Side Grip Belt Conveyor which is fully adjustable to suit different size products. Sortation Twin Lane Conveyor Trial system set up for a company to try their products on one of our Inclined Belt Conveyor. Plastic Modular Belt Conveying loose and packed wet wipes.

Best Deals from Conveyors

Gravity Roller Conveyor

Get Price Quote

Portable Mobile Conveyors

250,000 Per Set

We offer Portable Mobile Conveyors (4,6, 9, & 15 Meters Lengths, fully automatic motorized, easily movable any where as per requirement.

Conveyor System

Get Price Quote

Based in Pune (India), we have amassed lot of appreciation for manufacturing and supplying Conveyor System, which complies with prevailing industry norms. Our engineering team resorts to the use of best material & au courant techniques to fabricate Conveyor System, which meets or exceeds the desired performance expectations of our clients. Avail these durable Conveyor Systems from us, in specifications you desire, at highly fair prices.

Hot Air Oven

35,000 Per Piece

Hot air ovens are electrical devices which use dry heat to sterilize. They were originally developed by pasteur.[1] generally, they can be operated from 50 to 300 °c, using a thermostat to control the temperature. Their double walled insulation keeps the heat in and conserves energy, the inner layer being a poor conductor and outer layer being metallic. There is also an air filled space in between to aid insulation. An air circulating fan helps in uniform distribution of the heat. These are fitted with the adjustable wire mesh plated trays or aluminium trays and may have an onoff rocker switch, as well as indicators and controls for temperature and holding time. The capacities of these ovens vary. Power supply needs vary from country to country, depending on the voltage and frequency (hertz) used. Temperature sensitive tapes or biological indicators using bacterial spores can be used as controls, to test for the efficacy of the device during use.

Hopper Magnets

Get Price Quote

We are offering hopper magnets. hopper with / wothout abrasive resistant lining

Z Type Conveyor System

250,000 - 450,000 Per Piece

1 Piece (MOQ)

Dense Phase Conveying System

Get Price Quote

We are one of the renowned Manufacturers, Exporters, and Suppliers of Dense Phase Conveying System from India. Our Dense Phase Conveying System is widely demand in various industries due to its excellent performance and durability. Our Dense Phase Pneumatic Conveying Systems employs small amounts of high-pressure low-velocity gas to smoothly transit slugs of dry powdered or granular materials in controlled amount through enclosed convey lines. The System reduces the tear and wear of components like abrasive, fragile, friable, or mixed-batch materials. Features : Effective performanceLong operational lifeHigh strength Great resistance to weathering Handles varied kind of materials Affordable prices Advantages : Gently handles material Reduces product degradation Minimize component wear Reduces dusting Flexible routing

Gravity Roller Conveyor

250,000 - 350,000 Per piece

1 Piece (MOQ)

spray painting system

9,000 - 1,500,000 Per Piece

1 Piece(s) (MOQ)

Paint Baking Oven

Get Price Quote

We manufacture range of industrial oven whose main aim to make efficient utilization of heating fuel & reducing per piece production cost. Heating sources can be electric, gas & diesel version with direct & indirect fire options equipped with all best available safety features. Constructed in batch type OR conveyerised type with minimum heat loss care to suit specific requirements.

Polyester Ratchet Lashing Belt

290 Per Piece

10 Piece (MOQ)

belt elevator

125,000 Per Set

KOTI PLASTIC PROCESSING MACHINERY PVT LTD IS A LEADING MANUFACTURER OF BELT ELEVATOR LOADERS IN PUNE MAHARASHTRA INDIA BELT ELEVATORS ARE WIDELY USED IN MANY SECTORS FOR BULK LOADING OF PARTS OR MATERIALS

conveyor fabrication services

Get Price Quote

Our Conveyor Fabrication Services offer custom-built, high-quality conveyor systems designed for efficient material handling across various industries. We specialize in fabricating conveyors that are tailored to meet specific requirements, ensuring optimal performance, durability, and safety. Utilizing premium-grade materials and advanced techniques, our experienced team handles everything from design and engineering to installation. Whether you need a belt, roller, or chain conveyor, our solutions streamline operations, enhance productivity, and adapt seamlessly to your workflow needs, providing reliable, long-lasting performance.

Belt Conveyor Rollers

2,000 - 20,000 Per Nos

With the valuable assistance of skilled team of professionals, we are offering an extensive range of high quality Belt Conveyor Rollers Idlers. Our conveyor roller is widely demanded in the market due to the unmatched quality and unsurpassable performance in respective applications. Also, our conveyor roller is widely used for easy material handling in mining & metallurgy. Our valuable customers can avail this conveyor roller from us in customized option within promised time frame.

Vacuum Conveying System

225,000 Per Piece

01 Piece (MOQ)

Casting Cooling Conveyor

208,000 Per

1 Piece (MOQ)

conveyor ball rollers

Get Price Quote

conveyor ball rollers, Shaft Coupling, Connectors, Bushings

Powder Transfer Systems

Get Price Quote

10 Sets (MOQ)

Dilute phase transport: negative pressure system Negative pressure systems generally use positive displacement (roots type) exhausters providing up to 50% vacuum to convey materials through a pipeline to the destination where the air and product are separated at a receiving vessel with a filter, or a cyclone. The product enters the convey line directly, or if metering is required, via a special feeding device such as a rotary valve or screw feeder. The conveyed product is discharged from the receiving vessel either on a continuous basis by a rotary airlock or intermittently by valves to surge hoppers, storage vessels or other discharge points. In vacuum conveying, no moving parts contact the materials and no dust can escape into the atmosphere. Because of this superior leak containment, they are often specified on the basis of cleanliness, particularly when handling hazardous materials. The drawback of this system is that if the loading is high or the length of the system is large, the components must be designed for high vacuum. This adds cost to the components and must be considered when comparing methods of transport.

Gravity Roller Conveyor

2,500,000 Per Piece

Food Handling Conveyors

300,000 Per Piece

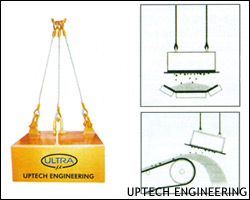

Suspension Magnet

Get Price Quote

SUSPENSION MAGNET Most Effective for removal at tramp iron from materials carried over. It is supended on the conveyor on the conveyor belt. It is mostly suitable in coal mines, food processing domestic waste.

Pneumatic Conveying System

Get Price Quote

Lean Phase Pneumatic Conveying system, Dense Phase Pneumatic Conveying system Plutontek, Designs & Manufactures, pneumatic conveying systems as a tailor made product, to provide solutions for bulk material handling. Design of system depends on the product characteristics, particle size, capacity, number of inlet sources and number of outlet / destinations, etc. Each pneumatic conveying system needs to be designed & customized as per the application given. Prime mover for conveying the product can be Roots blower, Compressor, Centrifugal blower, Centrifugal fan or Radial blower, depending upon bulk density of the material to carry, Length of the system, flow rate required and pressure required at outlet. System can run on both negative / positive pressure, depending upon the situation. At Plutontek, we have to consider all the given parameters to design the system and has to offer the optimum solution to customer in order to achieve economies in intial cost as well as running cost You can rely on us for all your customized requirements of : Dense Phase Pneumatic Conveying systems Lean Phase Pneumatic Conveying systems / Dilute Phase Pneumatic Conveying systems Combined Lean Phase and Dense Phase Pneumatic Conveying systems "Dense Phase Pneumatic Conveying system : The main principle of a dense phase conveying system is to slow down the velocity of the product in the pipe conveyor to a point that is below the speed at which the product breaks or degrades. At low velocities, the product lies for periods of time in the bottom of a horizontal line and it is blown under pressure to the discharge point in slugs or plugs. The dense phase pneumatic conveying systems uses low volume, medium pressure air stream and relies on a continuously expanding volume of air pushing cohesive slugs of material along the pipe. This system uses a transfer vessel / pump tank to feed the material into the conveying line. It is a batch system with plugs of material separated by cushions of air. The velocity range at the source can be as low as 200 fpm but rarely exceeds 2000 fpm. Dense phase technology reduces the air consumption to the absolute minimum by allowing the system to convey at maximum density. Dense phase conveying is mainly used for high capacity and long distance conveying." "Lean Phase (Dilute Phase) Pneumatic Conveying system : The main principle of a Dilute Phase conveying system / Lean Phase Pneumatic conveying system is to use a relatively large amount of air to convey a relatively small amount of material and at lower pressures than dense phase systems. The material is transported at high velocities through the system while being suspended in air. It is often referred to as suspension flow because the particles are held in suspension in the air as they are blown or sucked through the pipeline. To keep the material in suspension, it is necessary to maintain a minimum conveying air velocity. There is virtually no limit to the range of materials that can be conveyed with dilute - phase system. Products commonly conveyed in dilute phase systems include cement, fly ash, fine particles, flour, resins, specialty chemicals, ground feeds, and granular and palletized products. A dilute phase system will generally be lowest in capital cost but slightly costlier with operating cost compared to Dense phase conveying system which is exactly vice versa. This system also can run on both positive (pressurised) / negitave (vacuum) technique. ance conveying." "Combined Lean phase and dense phase pneumatic conveying system This system uses both - Combination of Negative - Positive Pressure i.e. pull-push system which has the advantages and benefits of both negative and positive pressure arrangements in a single system. These systems are used where there are multiple material entry points, and multiple delivery points. A very common application is the unloading of a standard railcar. This system of conveying is given only on specific customer demands."

Powered Roller Conveyor

Get Price Quote

At Infinity, we manufacture three types of roller conveyors including, powered roller conveyors, power & free roller conveyors, gravity roller conveyors. 1. Powered roller conveyors – These conveyors are driven by the chain and modular construction is standard with an adjustable leg support that eases installation and leveling on site. 2. Gravity roller conveyors – In this type, the material that needs to be conveyed moves down due to gravity over the roller bed.

Electric Ovens

Get Price Quote

We are entrusted with a task of providing Electric Ovens in the global market. The entire range is designed and developed in line with industry standards. We also make them available in different grades to meet unique and specific requirements. Renowned for their Easy function, reliable operation and low power consumptions, our Electric Ovens are of unmatched standards. Buyers can approach us for acquiring commercial electric ovens in temperature ranges. Highlights : High durability Tensile strength More about Electric Ovens The Ovens are double walled and made of SS 304 or as per customer's requirement. Insulated double walled metallic doors fitted with standard set of hardware with adjustable mesh. Belt Drive Motor Blower are Provided to maintain the temperature uniformly within the chamber. The Ovens are Durable, best performance & Low Maintenance. Imported Burners like Benton USA, ecoflame for Italy are used. Features : Transfer Mechanism : Conveyor Chain with slat/ A2/K2 attachments’, Honeycomb chains Semi-continuous, indexing type design Electrically /OIL/ Gas Heated Re-circulation Fans to ensure temperature uniformity better than +/- 5 degree C Torque limiters for safety. Pneumatically Operated chain tensioner PLC controlled. Capacity : 100 kgs / hour to 2000 kgs / hour.

modular conveyor belt

Get Price Quote

Rubber Conveyor Belt

Get Price Quote

A rubber conveyor belt is a type of continuous moving belt that transports materials or packages from one place to another. In other words, this is a solid band made of tough, long-lasting substances, upon which different materials are conveyed.

Conveyor Belt System

Get Price Quote

Being a high-flying name in this arena, we have developed a common network that links bank accounts and provide monetary exchange using bank deposits. The packaging procedure is supervised by our experts holding immense domain experience. Moreover, we make use of only quality packing material for ensuring complete safety of the orders during transit. We will produce all type of conveyors

IDLER ROLLER OD 30 MM TO 1200 MM OD

280 - 7,500 Per Nos

PIPE TH 3.3 MM IDLER 1 YAEAR WARRANTY BERING 62XX ZZ PIPE OD 30 , 40 , 45 , 48 , 50 , 60, 75 , 90 , 102 , 114 , 139 , 140 MM SIZ SHAFT 12 MM 15 MM 18 MM 20 MM 21 MM 22 MM 25 MM 26 MM 35 MM 40 MM 45 MM