SOFT MUD BRICK MOULDING MACHINE

his machine is based on Mould Chain (MC) principle which makes continuous and high speed production of green (raw) bricks possible. With every stroke, green bricks are ejected out of a mould on a metal pallet. It consists of a mixer, a mould chain, a press block, a mould washing station and an all-side sander (including exhaust box). Final adjustment of water content in the raw-mix can be done by adding 5 to 7 % water in the mixer.Loaded pallets coming out of the machine are carried to drying sheds and bricks remain on pallets till they achieve leather-hardness. Empty pallets are returned back to the machine.At present, ‘Ishtika’ Mixerpress has 4 Models – Model MC9, MC8, MC7 and MC5 – all based on mould chain principle and differing only in the number of cavities per mould.

...more

ROLLER CRUSHER-CUM-STONE SEPARATOR

‘Vipeshak’ roller crusher-cum-stone separator consists of two robust cylindrical rollers, one smooth and the other with helical groove, rotating in opposite directions. They are designed in such a way that stones contained in the incoming wet clay are stripped of clay, separated and eliminated through a chute. Smaller stones and inclusions of lower hardness are pulled through the roller gap along with regular material and crushed.

...more

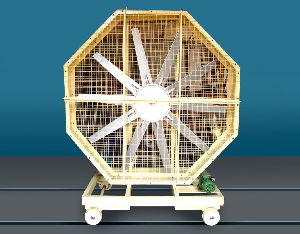

axial flow moving fan

The fan is of ‘axial flow’ type and it is covered with wire mesh casing and fitted on a wheeled trolley. It is dynamically balanced and hot dip galvanized for protection from rust due to aggressive/humid climatic conditions and for long life in drying shed / artificial dryer.

...more

Gripper

De Boer Gripper is a device which when attached to a fork lift or a grab crane can hold and move packs of bricks without pallets. Its fingers have movable pads on their sides which come out the moment load is transferred on to fingers and hold the lowest row or ‘legs’ of a brick stack laterally. This obviates the need for pallets or external props to support a brick stack while being lifted and moved. Therefore, once a pack of dry bricks is set, it can be moved from place to place – from drying yard to kiln to stock yard to truck to construction site – without a pallet and keeping the shape of the pack intact. This not only makes the pallets totally redundant, but also drastically reduces the labour intensity and multiple handling involved in movement of bricks, cutting huge operational costs and maintaining quality of green / fired bricks (by preventing chipping of corners and breakages)

...more

BRICK/BLOCK CUTTING SYSTEM

Extrudate Handling System (EHS) is used to cut extruded clay column into hollow slab, which is further cut into bricks/hollow blocks. It has an Idler Roller conveyor, Sliding Slab Cutter, Brick Cutting Table, Pallet Separating Conveyor and a Pallet Loading Conveyor. The wire-cut bricks/blocks are transferred on a metallic pallet and the loaded pallets are transported to drying site on trolleys.

...more

Box Feeder

Box Feeder is used to feed clay / raw-mix continuously. It consists of a trough fitted with moving metallic slat conveyor at its bottom. A rotating shaft with pedals / digging arms fitted at its discharge end provides uniform discharge while breaking clay lumps.2 Models of ‘Sambharak’ Box Feeder are available – SBF35 and SBF15.

...more

Belt Conveyor

Our conveyor belts have quality and features matching international standards and are optimised to meet specific requirements. The conveyor support frame is made of structural steel and transom is made of MS sheet with high precision laser cut CNC-bent profile and galvanized for rust protection and long life. The head and tail pulley drums are statically balanced. The drive pulley has a diamond patterned rubber friction lining. The troughing arrangement of the belt is two-roller type. The rubber belt for the conveyors is EP 400/3. The drive of the conveyor belt includes a helical bevel reduction gearbox and a motor. The front segment scraper is an adjustable type unit for positive pressure on the belt surface with scraper blades. The internal scraper is V-shaped structural frame with a rubber strip. For safe operation, suitable safety covers are provided around geared motors / drums and the rotating equipment on either side of the conveyor with pull chord switch arrangement at one side for emergency stop.

...moreBe first to Rate

Rate ThisOpening Hours