epoxy primers

550 Per Ltr

Epoxy HB Zinc Rich Primer

Get Price Quote

50 Litre (MOQ)

Best Deals from Decorative Paints

Online Leakage Putty

950 Per GMSKIT

5500 GMSKIT (MOQ)

Features : Fast Leakage repair Blow hole filling Tile filling Rebuilding restoration

NEXO Water base Non Burning Paint

258 - 265 Per KG

5 KG (MOQ)

Duracoat Epoxy Primer Paint

250 Per Litre

100 Litre (MOQ)

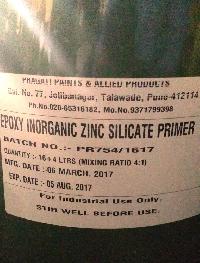

Epoxy Inorganic Zinc Silicate

Get Price Quote

10 Litre (MOQ)

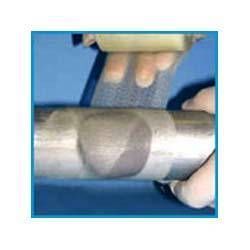

We are ranked among Manufacturers & Suppliers of premium Epoxy Inorganic Zinc Silicate in Pune, Maharashtra, India. Our Epoxy Inorganic Zinc Silicate is excellent for protecting metal surfaces from corrosion. It is a great primer used in various industries. Our company manufactures Epoxy Inorganic Zinc Silicate using up-to-date technologies with superior-grade raw materials. Buyers can order Epoxy Inorganic Zinc Silicate as per requirement and expect on-time delivery. Scope : A dual pack Paint possessing excellent durability & Weather properties. The product is designed to withstand a constant. Use : Recommended for use outside structural steel etc. Product Data : Type : Two Pack, cured with polyamide Composition : Epoxy resin/metallic zinc with silicon vehicle Application: Brush / Conventional spray. Recommended DFT : 50-60 microns. per coat. Theoretical Spreading Rate : 9.0-12.8 Sq. meter/Liter. Practical Spreading Rate : 6-7 Sq. meter/liter. Drying Time :Recoating : Minimum : 6-8 hrs. Surface Dry : 50 mins. Tack Free : 2 hrs. Handle : 4-5 hrs. Hard Dry : Overnight. Complete cure : 7 days Flash Point : Above 30°C. Colour : Grey Thinner : Pragati Make Epoxy Thinner ( PPCOAT EPX T200) Finish : Smooth & Matt. Temperature Resistance : continuous 200°C. Weatherability : Excellent. Flexibility : Excellent.0 Storage Life : Up to 9 month in intact condition or sealed the containers are kept under cover in a dry place under normal temperature conditions. Surface Preparation : Make full use of mechanical tools along with manual chipping & Wire brushing to remove loose particle rust sanding to Sa2 ½ sand paper. Excessive burnishing of steel is to be avoided. Application : Stir well when apply. To mix proper by manual or machine tool stirrer & apply brush, apply airless gun for achieved recommended DFT.Resistance Guide : Salt : Good Water : Good. Chemical : Fair Note : The mix primer must be used off within 3 hours for obtaining better finish. Do not apply when temperature falls below 10°C & when relative humidity rises above 90% do not apply during rain Fog or mist.

Epoxy Inorganic Zinc Silicate

Get Price Quote

styrene acrylic emulsions, Beestofix Max UPVC Cement, Flexo Paper Ink

Zinc Primer Paints

Get Price Quote

Champion Putty

Get Price Quote

We are offering "champion" putty is a gypsum based putty giving soft milky white finish. can be applied upto 4 mm thickness, giving us enough scope to flat level the surface. can be applied directly on rcc. no primer coat is required, no hand burns too while applying. per square foot coverage is comparatively higher.

Epoxy Paints

100 - 250 Per Litre

used as topcoats in epoxy flooring. appliction areas : industrial commertial pharmasutical hotels & resturants parking areas

Concrete Primer for Thermoplastic Paint

Get Price Quote

Shaf Sunrise Line Mark Pvt. Ltd. has a specially designed primer for application of Thermoplastic road marking material on concrete and old bitumen surface. The primer ensures excellent adhesion of the thermoplastic strips onto concrete or old bitumen, thereby increasing the life of road marking. Being quick drying and easy to apply, no significant time under-runs are expected owing to primer application. Colour - clear to translucent. Thermoplastic road marking paint, also called hot melt marking paint, is a powder base paint. When applied as road surface markings, need to heat upto 200 °C (392 °F), after which it is sprayed on the road surface. The coating then becomes a line after cooling. This paint is thick coating, wear-resisting, bright and reflective. In order to increase the antiskid performance of the line, thermoplastic paint has added reflective glass beads.The product is made up of selective use of plastic sized binders, reflective glass beads, extenders and pigments.General Characteristics Quick drying: The thermoplastic road marking paint should dry in a short time and no matter what climate it is. However the drying process is faster in winter than summer. It’s better to reduce the molten state temperature of the paint to cut down the hardening time. High durability: Compared to normal road paints, thermoplastic is hard wearing and is highly durable under all-weather all traffic conditions, its average life span is two to three years under normal traffic condition. Excellent adhesion: The thermoplastic road marking paint has strong connection with roads, it’s hard to break or peel off the paint from road surface. Coating agent is pre-painted to enhance the adhesion between thermoplastic road coatings and roads, that’s why their connection is so firm. Visual visibility: Whether it is day or night, thermoplastic road marking paint should be clear and visible within enough visual distance. It’s very easy to handle this in daytime since the visibility depends on the quality of the paint. But the visibility in the night depends on the reflective glass beads distribution and the temperature control during construction. For immediate effect, high Ratro reflective drop-on beads are recommended at the rate of 250 gm/sq.m. High skid resistance: Aggregate material of selected sizes are used in the product mixture and tested thoroughly to provide maximum required skid resistance for better road safety. High Softening Point: A good chemical formulation combined with years of Research and Development has yielded a product of exceptional stability against the effects of UV rays and harsh tropical climate conditions. Methodology for Application of Thermoplastic Road Marking Scope: This methodology is applicable for line marking on asphalt & concrete surface by using Thermoplastic Road Marking Material using Manual, Semi-automatic and Automatic Road Marking Equipment with attachment of Glass Bead Dispenser to spray Glass Beads. Machine: The work will be carried out by using fully automatic, semi-automatic or manual applicator machine. Pre-meltors for preparation of material will also be used to speed up the work and provide uniform pre-heating of the material, if necessary. The equipment used to lay hot applied thermoplastic material will be able to provide continuous uniform heating to temperatures of upto 200C, mixing and agitation of the material. Applications The Thermoplastic road marking will be executed by using Fully Automatic Machine or Semi-Automatic Machine. The thermoplastic material will be applied hot by Screening or Extrusion process. All surfaces to be marked will be thoroughly cleaned of all dust, dirt, grease, oil and all other foreign material before application of the marking. The lines through which the marking is to be done will be pre-marked by using distemper or any other pre-marking material. The desired settings for the markings (broken line, continuous lines etc.) will be made in the control panel of Automatic machine or the relevant size of screed box will be fixed to the applicator. The glass beads for super imposition on the markings will also be put into its container and settings to be adjusted at 250 grams per sqmtr. The glass beads applied to the surface of the complete stripe shall be applied by an automatic bead dispenser or by bead dispenser operating on gravity. The molten material will be allowed to pass into the screed box of the desired size (10 cms, 15 cms etc.) or adjusted in the automatic machine’s extruder unit. The screed box or the extruder unit will also be heated using the built in heaters. The machine will be driven through the pre-marked line and the screed box or extruder shutter is opened which will allow the material to flow to the surface and lay a uniform film of 2.5mm thick of thermoplastic material. Traffic Cones, Safety Jackets will be provided to divert the traffic from the main carriageway to the next lane / road to save the marking from the moving vehicular traffic. After the 30 – 60 min. of drying, road can be opened to traffic. For working on Portland Cement Concrete surface, a sealing primer from Any company shall be applied to the pavement in advance of placing of the strips to ensure proper bonding of the compound. The primer will be brush / spray machine applied @ 4-5 sqm per ltr. For marking of pedestrian crossings, directional arrows, chevrons etc. only manual applicator is used with 50 cms screed box and stencil wherever necessary. A team of well-trained staff would be executing the work strictly as per IRC-35 and MORTH specifications.

Marigold Wall Putty

Get Price Quote

ECMAPRIME PU

450 - 480 Per Kilogram

100 Kilogram (MOQ)

Single component low viscous moisture cured with hgith quality polyurethane base adhesive for concrete surface and structures as a priming membrane.

interior & exterior paint

8 - 50 Per Square Feet

As per word

graphite paint

Get Price Quote

Synthetic Enamel Paint

Get Price Quote

Synthetic Enamel Paint

Get Price Quote

We have reliable, legal, and secure payment procedures through which clients can make purchases. We maintain a high level of transparency and ensure to maintain proper documentation. We properly package our products using premium supplies and ultramodern technologies to make sure they endure shipping, handling, mechanical damages etc. We provide customized packaging solutions. Details : With the assistance of our diligent team, we are offering our clients synthetic enamel paints. We are sole distributors of Ugam and Pragat brands which are very high quality synthetic enamels used for household painting and industrial painting. Our entire range is manufactured in compliance with ISO 9001:2015 quality assurance system that ensures the end product conforms to set industry standards. We have a network of around 1200 dealers all over country, which helps us to deliver the consignments within the stipulated time frame. Features : Available in any shade More coverage and gloss than any other synthetic enamel of this type Water and chemical resistant Brand Name : UGAM Color : Any Place of Origin : Pune, Maharashtra, India The technical specification is correct to the best of our knowledge and under test conditions and we do not accept any liability towards misuse and contents of it. Product must be tested for specific use prior to use.Note : For further details or any queries please do not hesitate to contact us. Trade Information Product Code - Enamel Paints Brand Name - UGAM Minimum Order Quantity - 10 Unit of Measure - Liter/Liters Main Domestic Market - All India

cement wall putty

500 Per 40 Kilogram

We manufacture wall putty and all building color.we r in this work from last 30 years no compromise on quality.

Tielo Wall Putty

Get Price Quote

TIELO Wall Putty use for filling gap and cracks on wall and make smooth and finish for prepare color. wall putty make strength for binding wall with color and make decorative and smooth finish

KORRO-POL QUICK DRYING PAINTS

Get Price Quote

These Quick Drying Paints have very good Drying Time. They have very good corrosion resistance, Acid Resistance, Alkali Resistance & Water Resistance. They also have very good U. V. Resistance.

Epoxy Paints

100 - 250 Per Litre

We are offering epoxy paints. epoxy flooring can be applied over many different materials, including steel, concrete, and wood. However, concrete is the best surface for laying epoxy floors. Epoxy floor coating performance is directly affected by surface preparation. The integrity and the service life will be reduced significantly if the surface is improperly prepared. A proper surface preparation ensures epoxy coating adhesion to the substrate and prolongs the life of the epoxy coating system.

Berger Red Oxide Primer

180 Per Litre

50 Litre (MOQ)

Waterproof Cement Paint

Get Price Quote

Clean surface thoroughly with a stiff wire brush, to free it from dirt and algae. Previously painted surfaces should be washed or brushed down. If the surface is in flaky or powdery condition, it should be removed by scrapping or wire-brushing. Cement paints should not be applied on non-absorbent surfaces such as glazed bricks or previously painted enamel work. Saturate the surface with clean water several times, and allow excess water to disappear. Mix equal parts by volume of cement paint and water, and apply first coat with long hair brush. Do water-curing after 6-8 hours. Apply second coat 24 hours after application of first coat, and again cure with water after 6 hours. Two coats of Floracem are sufficient for most surfaces. Do not use saline water for mixing or for curing. No waterproofing compounds should be used either as a base coat, additive or top coat. Do not intermix different shades of Floracem. Restrict the use of blue, pink and green shades to interiors as they are liable to fleet on exterior applications. Avoid use of dark shades over large unrelieved areas.

Berger Primer

60 Per Litre

2000 Litre (MOQ)

Metallic Spray Paint

Get Price Quote

Being a customer oriented business entity; we are highly focused towards presenting to our customers an attractive consignment of Metallic Spray. Our offered tiles fixers are formulated under the supervision of accomplished employees of our crew making use of contemporary technology and supreme material. Along with this, these products are available in varied packaging options.

Texture Wall Finish

90 Per Square Feet

Wall Putty Cement Base

Get Price Quote

The product has now become very common and almost every new construction be it private home or commercial construction, the market has adopted the product blindly. wall putty provides a smooth and even finish to your walls for painting. wall putty helps to protect your walls and make them more durable by reducing weathering effects, water damage, etc. Specification Available Packs in 1kg/5kg/20kg/40kg

Quick Drying Paint

Get Price Quote

antifouling paint

Get Price Quote

1) Anti Fouling Paints-Merryguard-Premimum Exclusive-for Woden Boats 2) Anti Fouling Paints - Seagul-Premimum Exclusive-for Fibre Boats 3) Coaltar Bituminous Black Paints 4) Epoxy Top Coats : White Red Assorted Shades 5) Epoxy Redoxide Grey Primers 6) Zinc Chrome Red Yellow Primers 4) Zinc Phosphate Grey Primers 5) Glow Paint SY. Marine Enamels 6) Epoxy Thinners

Berger Bison Acrylic Distemper

308 Per Bucket

10 Bucket (MOQ)