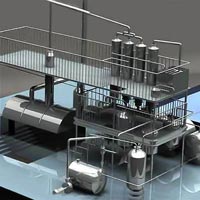

dewaxing plant

Get Price Quote

dewaxing plant

Get Price Quote

For selective Hydrogenation, Hydro de-sulfurization, Hydro dewaxing & Hydro cracking. For catalyst screening, their performance evaluation & comparison and to extract the kinetic data. Plant Details:Design temperature: 550°C, Reactor catalyst capacity: 150cc and 20cc for MCR, Unit included: two reactor system with updown flow mode with series, and parallel arrangement with on-line GC for product gas analysis.

Best Deals from Dewaxing Plant

dewaxing plant

Get Price Quote

Sunflower oil, with a relatively low FFA content is suitable for cold refining or centrifugal dewaxing. In this process, a small amount of acid is added to the crude oil and fed to a hydration tank. After a small retention, required caustic quantity is added into the mixer. This mixture is now fed to second centrifugal separator where waxes are removed along with soap. The dewaxed neutral is washed in the third centrifugal separator. The oil is then dried and sent to bleaching section.