Zinc Pressure Die Casting

430 - 450 Per One

Pressure Vessels

50,000 - 500,000 Per INR

1 Nos (MOQ)

Best Deals from Die Casting

Pressure Vessels

Get Price Quote

We are a Manufacturer and Supplier of Pressure Vessels from Pune, Maharashtra. We offer highly durable Pressure Vessels, after assuring high quality in the same. Also, Pressure these Vessels provided by us are easy to use and maintain. The company makes high strength Pressure Vessels available at affordable prices. Highlights Immaculate finishRobust constructionLonger service lifeMinimum maintenance

Pressure Vessels

Get Price Quote

30 Series Die Cast L Bracket for T slot Aluminum Profiles

15 - 35 Per Piece

1000 Piece(s) (MOQ)

Aluminium Laser Cutting Die

Get Price Quote

Pressure Vessels

Get Price Quote

Owing to our wide domain experience, we make available high capacity Pressure Vessels. These Pressure Vessels designed with precision and in accordance with standard specified in ASME Section VIII Div I. Our Pressure Vessels are sturdy in construction and remain in use for a long time. We make available wide range of Pressure Vessels in specifications as specified by the clients. We offer Pressure Vessels in different designs as specified by the clients. Specification : Air Receivers up to 60 m 3 capacity Standard Accessories : Safety Vales Drain Valves Pressure gauges

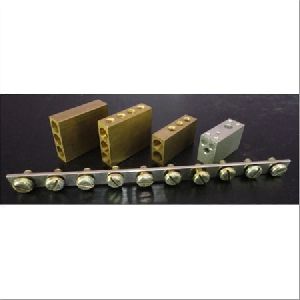

Brass Electrical Components

Get Price Quote

100 Piece (MOQ)

Aluminium Patterns Dies

Get Price Quote

Located at Pune(India), we are reckoned for providing excellent array of products throughout the country. We stringently follow automated warehousing system that helps us in meeting the safe storage requirements. Thus, we ensure zero damage to the products till the final dispatch.

Pressure Vessels

Get Price Quote

Pressure Vessels for the process industry . Vessels fabricated with 100% radiographic welding In house D.P testing , Hydraulic testing , Pnematic testing facilities available in house Radiography testing available inhouse All Jobs tested to 8kgcm2 as per ASME Standards

Pressure Vessels

Get Price Quote

Abhijeet Enterprises well facilitated infrastructural unit enables us to make a highly qualitative Pressure Vessel, which is developed by making use of excellent quality components. Features: Easy to use Quality tested Robust construction

Aluminium Gravity Die Casting

340 Per Kilogram

200 Kilogram (MOQ)

Crankcase Castings

Get Price Quote

The Crankcase Castings, provided by us, are manufactured using the best available grade of raw material as per customer requirement. Purchasers can place wholesale or retail orders with any time of the year and expect timely arrival of deliveries. Supported by an ultramodern packaging unit, we pack our products with premium materials and ensure their longevity. Courtesy our unit, we can provide customized packaging solutions too.

Vacuum Castings

Get Price Quote

Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required.

Pressure Vessels

Get Price Quote

We manufacture and export optimum quality pressure vessels which are extensively used in chemical industries. We offer stainless steel pressure vessels, cylindrical pressure vessels etc. Which are made up of high quality raw materials. Pressure vessels are used to provide heat treatment to different liquids under fixed pressure. We use optimum quality steel in our vessel which make help them withstand heat and stress. We can even customize our pressure vessels according to the client requirements. We have also become one of the trustworthy pressure vessels exporters from india.

Pressure Vessels

Get Price Quote

01 Piece(s) (MOQ)

pressure vessels are designed and manufactured in accordance with asme viii div 1, and other similar international pressure vessel construction codes for the chemical, petro-chemical, pharmaceutical, cosmetic, food and beverage industries.vessels can be designed for internal and external pressure and vacuum conditions.further options include fatigue life design, thermal analysis and finite element analysis (fea). materials of construction include:stainless steels 316/316l, 304/304l, 317l, 321, 904l, duplex, super duplex, incolloy & monel, clad (explosion bonded) welding processes include tig and smaw, mig, flux cored (fcaw) quality controls throughout the manufacturing process ensure plant integrity and customer satisfaction. With all work being carried out to the standards in accordance with customer and design code requirements by our highly skilled craftsmen and technicians inspection capabilities include radiography, ultrasonic, positive material identification (pmi), mpi and dpi. As well as carrying out hydrostatic testing and surface finish roughness measurements. comprehensive documentation packages are supplied with each vessel upon completion.including declaration of conformity, design approval certificates, drawings, calculations, material certificates and data sheets, ndt reports, hydrostatic test certificates, weld procedures and welder qualifications

low pressure die casting

Get Price Quote

Big Tilt Gravity Die Casting

Get Price Quote

Gravity die casting

Get Price Quote

We are rated amongst the trustworthy Manufacturers and Suppliers of Gravity Die Casting. The Gravity Die Casting, offered by us, is being manufactured keeping in mind the set industrial standards. We have a wide distribution unit in order to handle the bulk orders of Gravity Die Casting. Applications : Automobile Railways Agricultural equipment Medical equipment

Pressure Vessels

Get Price Quote

Manufacturing and exporting an optimum quality range of Process Reactors that finds usage in solvent & fusion process for making Alkyd, UF, MF and Phenolic Resins, Paints, Dyes, Minerals, Oil & Gas, Petrochemcials & Pharma Drugs, Brewery, Sugar Pans, Distillery etc. We offer reactor plants such as cooking vessels, reflux condensers, total condensers, separators, receivers and thinning vessels in various technical specifications. Our quality-approved reactors are also used in industries such as chemical, food & beverage and others. Quality tested grades of stainless steel, hastelloy, titanium and nickel, among others are utilized in the fabrication of these equipment. These reactors are stringently checked to ensure their long service life and crack resistant & leakage proof features. Used for a wide range of applications in large chemical treatment plants and nuclear reactors, our technically advanced products have helped us carve a niche in the industry. Further, reactor vessels manufactured by us are also used in many industries to contain as well as control chemical reactions. Acme manufactures a wide range of pressure vessels, each custom built to fulfil ACME Sec VIII Div I code and client’s individual requirements for both onshore and offshore use. Pressure Vessels have been produced with different type of materials like Carbon Steel, Stainless Steels (including Duplex alloys), Nickel & Nickel Alloys (including hastelloy, Inconel) and Cladding of specified materials (PTFE, PP, FRP). Recognised as one of the top vessel manufacturers. High quality standards to ensure easy functioning under various pressures. Highly durable PVs for more work efficiency & Optimum engineered product.

Pressure Vessels

Get Price Quote

PRESSURE VESSELS Pressure Vessels are most commonly used in almost all industries like- Refineries, Chemical plants and Fertilizer plants.These pressure vessels are mainly used as Gas storage, Water storage, Air receivers, Separators, Fuel Tank and Buffer Vessels.

Pressure Vessels

Get Price Quote

These Pressure Vessels are manufactured as per various codes like ASME, PED, IS, BS, DIN or any other standard as per customer requirement. Satyam Industries have excellent welding facilities which include GTAW / FCAW/SMAW & SAW. The entire welding is carried out under expert supervision using world best consumables. All the welding procedures and welders have been approved by renowned inspection agencies. We have skilled work force to manufacture quality equipments in different material of construction like carbon steel, stainless steel, duplex steel, Hastelloy, Titanium, Inconel, & many others. the range of pressure vessels manufactured is as follows. • Our Product Range & Capacity: • Pressure Vessels, Tanks, Silos. • Capacity Max. Thickness – 30 mm • Max. Diameter - 4.5 mtrs • Max. Length - 10 Mtrs. Or more • Max Weight - up to 25Tons. Material of Construction - Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, Monel, Hastelloy, Inconel and many more. We also carry out all levels of Non-Destructive Testing (NDT) including: Leak Test, Hydraulic Pressure Test, Vacuum Test, Heat Treatment and Proof Load Test. Products can be finished by bead and shot blasting, painting, polishing, pickling and passivating. Depending on size, products can also be glass or rubber lined and electro polished. • Satyam manufacturing pressure vessels for wide variety of applications in different industries like. • Water Treatment Industries • Chemical Industries • Petrochemical Industries • Refrigeration Industries • All Process Industries

Aluminium Components Dies

Get Price Quote

CAM (Computer Aided Manufacturing) is Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is a programming tool that makes it possible to manufacture physical models using Computer Aided Design (CAD) programs. CAM creates real life versions of components designed within a software package. CAM was first used in 1971 for car body design and tooling.

Aluminium Die Casting

Get Price Quote

Gravity Die Castings

322 Per Kilogram

500 Kilogram (MOQ)

Die Cut Components

Get Price Quote

We offer Die Cut Components, which are useful for packaging of electrical devices, enclosures and a variety of other electrical applications. These Die Cut Components can also be customized as per the customers� packaging requirement. The Die Cut Components are precision-engineered for various applications. The Die Cut Components are available in various designs and dimensions for diverse applications.

Pressure Vessels

Get Price Quote

Casting and Forging Components

Get Price Quote

Intercontinental Exim Corporation Company is well known Casting & Forging components supplier, producers and exporters from India. We can source forged products in a range of different materials, including STAINLESS STEEL, High carbon, Medium carbon, Low carbon, ALLOY. We are ISO 9001:2015 guaranteed supplier and exporter of in agricultural forging, automotive forging, conveyor forging, forging for mining, saddler forging, safety equipment forgings, shipping & lifting equipment forgings, vintage motorbikes forgings, diving equipment forgings, lock forging, etc. We offer these items in different sizes and different details to the customers. Every one of the items offered by us is made in adherence with the worldwide quality guidelines Today we are one of the best casting components supplier & exporter from India. We offering end-to- end solutions across the entire value chain and delivering best-in- class Gravity & Low Pressure casting (Aluminium Casting / Ductile Casting / Green Sand Casting /shell casting) to our customers at the most optimum costs. We are also pioneers of the unique Pie system for low pressure die casting – a system which enhances productivity with minimum utilization of resources like machines, space and manpower. To learn more about Casting & Forging Components and our other services, please contact Incoexco.

Pressure Vessels

Get Price Quote

Pressure Vessels

Pressure Vessels

Get Price Quote

Supplier & Manufacturer of Pressure Vessel & Shells for Pressure Vessel. Our product range also comprises of Fabrication, Tank and Base Frames. These Pressure Vessels are fabricated using superior grade basic material to ensure their compliance with defined industry standards.