Pressure Vessels

Get Price Quote

We manufacture and export optimum quality pressure vessels which are extensively used in chemical industries. We offer stainless steel pressure vessels, cylindrical pressure vessels etc. Which are made up of high quality raw materials. Pressure vessels are used to provide heat treatment to different liquids under fixed pressure. We use optimum quality steel in our vessel which make help them withstand heat and stress. We can even customize our pressure vessels according to the client requirements. We have also become one of the trustworthy pressure vessels exporters from india.

Pressure Vessels

Get Price Quote

01 Piece(s) (MOQ)

pressure vessels are designed and manufactured in accordance with asme viii div 1, and other similar international pressure vessel construction codes for the chemical, petro-chemical, pharmaceutical, cosmetic, food and beverage industries.vessels can be designed for internal and external pressure and vacuum conditions.further options include fatigue life design, thermal analysis and finite element analysis (fea). materials of construction include:stainless steels 316/316l, 304/304l, 317l, 321, 904l, duplex, super duplex, incolloy & monel, clad (explosion bonded) welding processes include tig and smaw, mig, flux cored (fcaw) quality controls throughout the manufacturing process ensure plant integrity and customer satisfaction. With all work being carried out to the standards in accordance with customer and design code requirements by our highly skilled craftsmen and technicians inspection capabilities include radiography, ultrasonic, positive material identification (pmi), mpi and dpi. As well as carrying out hydrostatic testing and surface finish roughness measurements. comprehensive documentation packages are supplied with each vessel upon completion.including declaration of conformity, design approval certificates, drawings, calculations, material certificates and data sheets, ndt reports, hydrostatic test certificates, weld procedures and welder qualifications

Best Deals from Die Casting

Die Cut Components

Get Price Quote

We offer Die Cut Components, which are useful for packaging of electrical devices, enclosures and a variety of other electrical applications. These Die Cut Components can also be customized as per the customers� packaging requirement. The Die Cut Components are precision-engineered for various applications. The Die Cut Components are available in various designs and dimensions for diverse applications.

Press Tool Dies

Get Price Quote

Namkala Solutions are a leading firm for providing an extensive range of Press Tool Dies to our valued patrons. This product is offered in diverse specifications. Features: High strength Easy to use Durability Longer service life

Pressure Vessels

Get Price Quote

Enersys has acquired thorough knowledge and experience in design and manufacturing of pressure vessels as per ASME Sec-VIII, Div-1 and all the related standards for materials and inspection. Our design engineers have prolonged experience to design various parts as per the rules of relevant standard. Enersys has own quality management system with standard procedures, sample forms and records formats in QC system and QC manuals besides the ones provided by ASME, which are only for WPS (Welding procedure specification) and PQR (Procedure qualification record), but not for other manufacturing activities. Pressure vessels are used in a variety of applications for Oil & Gas, Petrochemicals, Refineries, Water Treatment Plants, Refrigeration Plants and other Chemical Industries. They appear in these sectors as industrial compressed air receivers, domestic hot water storage tanks, distillation towers, pressure reactors, autoclaves, pneumatic reservoirs, hydraulic reservoirs under pressure, storage vessels for liquefied gases, shells of heat exchangers, etc. Enersys vessels are engineered with adequate safety factor, corrosion allowance, conservative design temperature and pressure. Necessary nondestructive testing, such as ultrasonic testing, radiography, and pressure tests (hydro or pneumatic) is carried out by experienced engineers.A Deareators is used for the removal of air and other dissolved gases from the feed water to steam generating boilers. The dissolved oxygen in boiler feed water causes serious corrosion damage in steam systems by attaching to the walls of equipment and forming oxides (rust). It also combines with any dissolved carbon dioxide to form carbonic acid that causes further corrosion. Most Deareators are designed to remove oxygen down to levels of 7 ppb by weight (0.0005 cm³/L) or less. Spray & Tray Type Deaerating Heaters Spring-loaded nozzles located in the top of the unit spray the water into a steam atmosphere where the steam heats water and at the elevated temperature the solubility of oxygen is extremely low and most of the dissolved gases are removed from the system by venting. The spray will reduce the dissolved oxygen content to 20-50 ppb, while the scrubber or trays further reduce the oxygen content to approximately 7 ppb or less. For optimum oxygen removal, the water in the storage section must be heated to within 3 º C of the temperature of the steam at saturation conditions. From inlet to outlet, the water is deaerated in less than 10 seconds

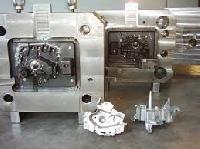

Cast Iron Die

Get Price Quote

Aluminium Components Dies

Get Price Quote

CAM (Computer Aided Manufacturing) is Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is a programming tool that makes it possible to manufacture physical models using Computer Aided Design (CAD) programs. CAM creates real life versions of components designed within a software package. CAM was first used in 1971 for car body design and tooling.

Pressure Vessels

Get Price Quote

Pressure vessels can theoretically be almost any shape, but shapes made of sections of spheres, cylinders, and cones are usually employed. Detailed Description A common design is a cylinder with end caps called heads. Head shapes are frequently either hemispherical or dished (torispherical). More complicated shapes have historically been much harder to analyze for safe operation and are usually far more difficult to construct. Pressure vessels are used in a variety of applications in both industry and the private sector. They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks.

Gravity Die Castings

Get Price Quote

Gravity Die Castings, Alloy Wheel, E Rickshaw Alloy Wheel, Atv Alloy Wheel

low pressure die casting

Get Price Quote

low pressure die casting, Stator Case Permanent Molds, Gear Casting Housing

Beryllium Copper Plunger Tips for Die Casting

Get Price Quote

Beryllium Copper Plunger Tips for Die Casting

Casting Dies

Get Price Quote

Casting Dies, core boxes, gravity die, patterns

Vacuum Casting

Get Price Quote

Vacuum Casting, Ferrous Casting, Non Ferrous Casting, Pressure Die Casting

Pressure Vessels

Get Price Quote

Pressure Vessels, chemical plant machinery, Conveyor Systems

Aluminum Pressure Die Casting

Get Price Quote

Aluminum Pressure Die Casting, Aluminum Electric Motor Housing

Pressure Vessels

Get Price Quote

Pressure Vessels, Air Receivers, compressor chassis

Aluminium Pressure Die Castings

Get Price Quote

Aluminium Pressure Die Castings, Cylinder Head Cover, oil pans

powder compacting dies

Get Price Quote

powder compacting dies, hex dies

aluminum sand die casting

Get Price Quote

aluminum sand die casting, metal shaft, cylindrical gear

Aluminum Die Casting

Get Price Quote

Aluminum Die Casting, patterns, Sheet Metal Press Tools, Welding Fixtures

Sand Casting

Get Price Quote

Sand Casting, Aluminum Casting, Gravity die casting, Non Ferrous Casting

Die Casting Components

Get Price Quote

Die Casting Components, Industrial Gauges, Fabrication Equipment

dies casting press tools

Get Price Quote

dies casting press tools, Casting Dies, compressing moulds

Die Casting Components

Get Price Quote

Die Casting Components