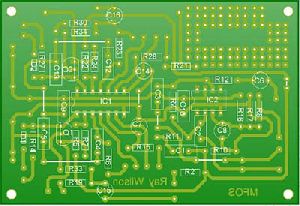

Single Sided PCB Circuit Board

A printed circuit board with a conductive circuit pattern one side only. Holes in the board are usually not plated through.A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate.Alternative names are printed wiring board (PWB), and etched wiring board. We manufacture an exclusive gamut of single sided printed circuit boards are available in various thickness and track widths. We manufacture single sided printed circuit boards that sizes from 0.4mm to 3.2mm thickness with the thickness of the copper 18-35-70 micron as per requirement.These single sided printed circuit boards are widely used in various electronics applications. Being single sided circuit board, it connects various electronic components electrically. We can provide customization to our range of single sided printed circuit boards. Single sided PCB’S have been around since the late 1950s and still dominate the world market in sheer piece volume. Single-sided printed circuit boards are easily designed and quickly manufactured. They serve as the most cost effective platform in the industry.Diya Electronics produces prototype, midrange volume Single Sided circuit boards, with a different copper thickness. High Operating temperatures range. Single sided boards are available with surface finishes including both leaded and lead-free Hot Air Solder Level (HASL).

...more

single sided circuit boards

A printed circuit board with a conductive circuit pattern one side only. Holes in the board are usually not plated through. A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. Alternative names are printed wiring board (PWB), and etched wiring board. We manufacture an exclusive gamut of single sided printed circuit boards are available in various thickness and track widths. We manufacture single sided printed circuit boards that sizes from 0.4mm to 3.2mm thickness with the thickness of the copper 18-35-70 micron as per requirement. These single sided printed circuit boards are widely used in various electronics applications. Being single sided circuit board, it connects various electronic components electrically. We can provide customization to our range of single sided printed circuit boards. Diya Electronics produces prototype, midrange volume Single Sided circuit boards, with a different copper thickness. High Operating temperatures range. Single sided boards are available with surface finishes including both leaded and lead-free Hot Air Solder Level (HASL).

...more

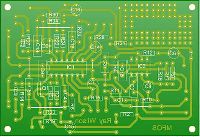

Double Sided PCB Circuit Board

Double-Sided PCB are a step above single sided in their complexity. Double Sided PCB require plated through holes to provide better anchoring for soldered components and front to back electrical continuity.Most designs require solder mask front and back along with a silkscreen layer for component designators. Very often double sided designs utilize mixed technologies of through hole (PTH) and surface mount (SMT).Double Sided PCB circuits were the gateway to higher technology applications. The advent of the plated thru hole was quickly adapted and allowed electronic designs to expand in capability and shrink in physical size.Today the double sided printed circuit board technology remains the workhorse of the assembly industry. There are near limitless applications for old and new designs. Fine line surface mount, ultra high copper build, high and low temperature, Solder coated, Silver, and Gold finishes are just a few examples of DSPT applications.Diya Electronics produces prototype, midrange volume Single Sided circuit boards, with a different copper thickness. High Operating temperatures range. Single sided boards are available with surface finishes including both leaded and lead-free Hot Air Solder Level (HASL).

...more

Double sided PCB

Double-Sided PCB are a step above single sided in their complexity. Double Sided PCB require plated through holes to provide better anchoring for soldered components and front to back electrical continuity. Most designs require solder mask front and back along with a silkscreen layer for component designators. Very often double sided designs utilize mixed technologies of through hole (PTH) and surface mount (SMT). Double Sided PCB circuits were the gateway to higher technology applications. The advent of the plated thru hole was quickly adapted and allowed electronic designs to expand in capability and shrink in physical size. Today the double sided printed circuit board technology remains the workhorse of the assembly industry. There are near limitless applications for old and new designs.

...more

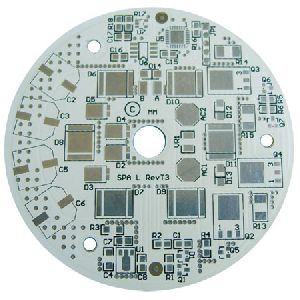

Aluminium PCB Circuit Board

Diya Electronics has been producing Aluminum Printed Circuit Boards (also called Metal base PCB). Although, originally envisioned for use in the power-supply industry these substrates are now most widely used in High Brightness LED products. There are many names for these products; Aluminum clad, Aluminum base, Metal clad (MCPCB), Insulated Metal Substrate (IMS or IMPCB), thermally conductive PCB, etc. but they all mean the same thing.Aluminum PCB is a unique metal-based copper clad laminate; it has good thermal conductivity, electrical insulation and machining performance. Aluminum PCB market mostly Fuchs Wright aluminum substrate. Common in the LED lighting products.Aluminum PCB is one of metal-based pcb, including copper foil, thermal insulating layer and metal substrate, its structure divide into three layers :• Circuit layer: the equivalent of an ordinary PCB, copper thickness from 1oz to 10oz.• Insulation layer: Insulation is a layer of thermal insulating material with low thermal resistance. Thickness: 0.003 "to 0.006" inch is the aluminum pcb core technology.• Based Layer: a metal substrate, usually aluminum or copper may be chosen. The heat dissipation afforded by this construction is dramatically superior to standard FR-4 constructions. The dielectrics used are typically 5 to 10 times as thermally conductive as conventional epoxy-glass and a tenth of the thickness resulting in thermal transfer exponentially more efficient than a conventional rigid PCB.Although Power Converters and LEDs are the largest users of these products, Automotive and RF companies are also looking to take advantage of the benefits of these constructions. A single layer construction is the simplest, most thermally conductive and most cost effective construction. Designs with higher component counts may not have room for all the required routing on a single layer. In this case a two layer design is required. A thin sheet of dielectric, typically around .006” thick, is drilled, plated and etched much like a standard double sided printed circuit board. The sheet is then laminated using thermally conductive bonding material to the metal base. This extra routing layer results in components farther away from the heat-sink and reduced heat transfer so this construction is recommended only when necessary.

...moreBe first to Rate

Rate ThisOpening Hours