Cyclone Dust Collector

50,000 Per Set

Bag Filters

Get Price Quote

Bag filters, separate particulate from gas stream by causing the particulate to pass through a filtering media, a layer of previously collected (or purposely deposited) particulate, or both. To prevent excessive pressure drop as the particulate accumulates, these devices use various mechanisms to disengage the particulate from the media.

Best Deals from Dust Collectors

SMALL CAPACITY CENTRIFUGAL BLOWERS

Get Price Quote

Sensoheat Designes and manufactures small capacity centrifugal blowers with various ratings as 40W, 90W, 180W and varied CFM as per requirement. These kind of centrifugal blowers find their applications in composting machines, exhaust and many more.. These blowers can also be designed to be operated on D.C. Supply. Blowers with built in motors can also be supplied as per your application.

Air Blower

Get Price Quote

We hold expertise in manufacturing and supplying a wide range of Air Blowers. These devices are based on advance technologies and acclaimed for their compact size and uninterrupted performance. Engineered using best available technologies and following world class standards, these Air Blowers ensure user friendly application and high functional efficiency. Our Air Blowers provide vibration free performance and easy maintenance.

Centrifugal Blower

38,551 Per Piece

1 Piece (MOQ)

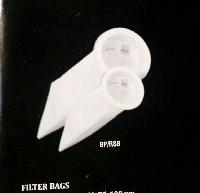

White Polypropylene Bag Filter

300 Per Piece

5 Piece (MOQ)

Bag Handling System

Get Price Quote

Shot Blasting Dust Collector Bag

Get Price Quote

50 Piece (MOQ)

MSEP Multi Bag Filter

500,000 - 1,500,000 Per Set

1 Set (MOQ)

Centrifugal Blowers

Get Price Quote

Pulse Jet Bag Filter

Get Price Quote

Green Tea Bags

Get Price Quote

We are the main supplier of this product.

Industrial Filter Bags

Get Price Quote

Micron : 1, 5, 10, 25, 50, 75, 100 umThe BP series bags are made of nonwoven needle felt with glazed finish PP. This finish is created by melting of the outermost surface fibers producing a bond which reduces the possibility fo migration. The PP molded top and the ends are ultrasonically welded together.The RSB series of bags are made of three layers of media. The inner layer works as a pre-filter which is made of coarse Nylon mesh, the center layer is non-woven felt which does the actual filtration and the outermost layer is made with super fine spun bond fabric for final filtration. The unique Rubber collar ensures O bypass & 100% seal and very accurate filtration.Configuration : BP : Dia 4" x 10" & 20" RSB : Dia 7" x 17" & 32" Flow per 10": 100 LPM for 10" BP series and 200 LPM for 17" of RSB for raw water with operating pressure of 2.5 bars.

Belt Driven Blowers

Get Price Quote

We make smooth and on-time deliveries of the product range that we keep safe in our capacious inventory. Now procure Belt Drive Blower at extremely reasonable prices from us. Our organization is its famous supplier.

Gas Blower

500,000 Per Unit

Bag Filters

Get Price Quote

We have superior storage facility to keep large product range that we make available. In order to meet elevated quality norms, we keep it updated with modern work methods. This is due to our streamlined packaging system that we are able to meet the customized and standard packaging requirements of the clients. Moreover, we ensure complete safety of the products. Applications : Cement Starch Detergent Biochemical Food industry Paint industry Bulk chemicals Pharmaceutical Dyes & Pigments Ceramic industry Mining & Minerals Features : Top Quality Media Easy removal of bags for cleaning. Tailored to suit customer requirement. Temperature range from -35o C to 400 oC Various options of filter media to suit the process. Designed to operate at lower pressure drop thus reducing the power requirement

Industrial Bag Filter

Get Price Quote

Owing to a vast experience and profound knowledge, we have emerged as a major Manufacturer and Supplier of Industrial Bag Filter. Our entity is based in Maharashtra, India. We have an experience of control flue gas generated from wood coal lignite boiler as per pollution control board norms. We are manufacturing bag filters as per the prescribed emission limit, spm & also manufacturing packed bed scrubber if sulphur gas is a constraint. Our bag filters are suitable for high-temperature flue gases. Our bag filters are also optionally equipped with safety devices like pre-cyclone multi clones, dilution bypass, damper insulation to prevent the major temperature losses inside the housing.

Flowers Mill Dust Collector

21,000 Per Piece

01 Piece (MOQ)

Double Inlet Blowers

4,000 Per Piece

5 Piece (MOQ)

We are manufacturers

Lug Brushing Machines with Dust Collector

Get Price Quote

A side view of the machine with brushing arrangement clearly visible. The dust collection is effective & behind the brush mechanism with blower fan on top. Salient Features: No pollution & hence operator friendly Productivity automatically enhanced. Scrap generation collected in tray. Environment protected. Filter media automatically pulsed periodically by use of timers. Equipment is lightweight & hence easily portable Utility Requirements: Brushing motor needs 0.5 H.P. Power Blower motor needs 1.5 H.P. Power Compressed air required at 4 Kg./cm2 for periodic pulsing of filters. Control Panel: Wall mountable design. Operation on wall mounted panel restricted to blower motor start & stop only. Brush motor operation on the grinder for easy start & stop function. Panel input connection is simple with only one three phase incoming supply. Output connection from panel to be given to blower motor & brushing grinder motor & solenoid coil of pulsing valve. FAQ's 1. How important is lug brushing? Is it really necessary? Lung brushing is important and hence necessary prior to group welding in the assembly department since removal of oxide from the lugs exposes the metal surface thereby ensuring a proper welding and bonding of the plates to the busbar. 2. In what way is lug brushing on machine butter compared to filing the plates? Manual filing of plates can result in uneven lug thickness causing lead runs during grouping. Such lead runs if undetected can be the reason for cell shorts and battery failure. Thus it is a quality related issue. Moreover filing of plates manually is laborious, time consuming and hence not economically viable. Further – in addition to productivity the rate of production with manual filing is low and hence unviable considering the competitive nature of today’s business environment. Lastly and not the least – manual filing is polluting whereas the lug brushing machine having the integrated dust collector ensures that the lead dust is collected in a tray resulting in substantial savings for today’s battery manufacturers clean setup. 3. Can the machine be used for industrial plates lug brushing? The machine can be used for positive & negative plates of standard size as well as narrow size automotive plates in addition to using these for all industrial plates. 4. How frequently does the filter media need cleaning? Cleaning of the filter media is done periodically with the help of compressed air. It is for this purpose thatcompressed air forms part of this machine’s utility requirement. A timer in the control panel ensures cleaningof the filter at regular intervals of one minute.

Bag Filter Housings

Get Price Quote

Consider our name, if seeking for precision engineered Bag Filter Housings! Based in Maharashtra, India, we have all the in-house integrated facility to fulfill varied demands of the buyers. Available with us in different specifications, our products have no match in the market. Furthermore, we keep a large stock and ensure timely deliveries of consignments. Bag Filter HousingFludisation is the introducing of a compressed gas, via porous media, into a bulk powder, to enable the powder to behave like a liquid for ease of movement.Salient Features : Custom made design to meet required specifactions of materials, strengths, flow requirements, thickness and micron rating. High Dirt Holding Capacity. Pulse Jet Cleaning System : Uses high pressure air directed down into the clean side of a filter bag in order to remove the dust cake from the surface of the media. Cleaning mechanism allows bag houses to be cleaned while the system is online. Operates at lower pressure drops and with lower space requirements. More complete cleanings than shaker or reverse air bag houses, lengthening bag life. MOC Body : SA 516, SA 304, SA 316 or as per application. MOC Bag : polyester (400GSM, 500GSM, 550GSM, 600GSM ) [ Acrylic Homopolymer (pan) – 550GSM / 600 GSM, ] Polypropylene-- 550GSM PPS (Ryton) – 550 / 600 GSM [ Polymide (PP4)- 550 /600GSM, ] PTEE (Teflon)- 7509 gsm Silo and hopper Fabrication as per required. Typical Appications Steel Industry : Furnace – process / Material Handling, Cast House /Stock House, Boiler, Kiln / Reactor Exhaust, Coal prepation / Injection, coke oven. Cement Industry : Clinker Cooler, Coal Mill, Cement Mill, Kiln / Reactor Exhaust, Transfer poiint Dedusting, Alkallin Bypass. For material handling and Boiler : Power, Agro Based, Sugar, Rice Tobacco, Breweries & Distilleries, Clinker Cooler, Coal Mill, Cement Mill, Kiln / Reactor Exhaust, Alkali Bypass, Diary, Drugs & Pharmaceuticals, Food processing, paper & Pulp, Solvent Extraction / Edible oil, Sponge Iron, Textiles, Soaps, Detergents & Waves.

Dust Collection System

Get Price Quote

We are acclaimed as one of the prominent Manufacturers, Exporters, and Suppliers of Dust Collection System in India. Our Dust Collection System is installed in various industries for filtration of air from dust particles generated by plant in the industry. Our Dust Collection System assurance of full safety from hazardous materials in working environment Components : Exhaust hood Ductwork Dust collector Fan and Motor Features : Effective performance Easy to clean and maintain Sturdy construction Longevity Hassle free function Cost effective Applications : Plastic Processing Industry Pharmaceutical IndustryAir conditioning PlantsFood processing Industry Cement and Mineral IndustryPowder Coating Industry

Multi Cyclone Dust Collector

Get Price Quote

The flue gases coming out of the boiler contains dust particle’s embedded in it.The pollution control board of a particular area has limitation on the concentration of dust particles in the gases which are to be release from boiler to the atmosphere.n order to minimize this dust content from the flue gases dust collector system is being used.The main structure due to which the separation takes place is a pipe in pipe construction.The lower side of the outer pipe is tapered downwards.Two duct openings are placed on the flue gas inlet and outlet sides with flanges.

Centrifugal Air Blowers

Get Price Quote

Centrifugal Air Blowers and Fans are used for delivering air at substantial pressure. Our Centrifugal Blowers are designed to work at precise operating flow and pressure condition. All our Centrifugal Air Blowers comply with IS-4894 code. We provide Centrifugal Air Blowers which are known for their excellent performance and efficiency. We provide these Centrifugal Air Blowers at nominal prices. Inputs Required For Selection Of Blower Air flow rate required by the process in m3/Hr. or CFM (cubic feet/ min.) Static pressure as offered by the ducting. In inches/ mm of wc(needs to be calculated based on ducting design) Temperature at which Air enters into the blower Output Specification Of Blowers Blower Wheel Diameter Rotation speed in rpm Power Consumption in H.P. or Kw Motor Power in H.P. Inspection and Testing: Testing Certificates Provided Along With Blower Impeller Wheel Balancing Certificate Operating characteristics Curve showing the blower performance at different values of static pressure Blower noise level at operating point

Dust Collector Fan

Get Price Quote

The company is a notable Supplier of Dust Collector. The Dust Collector we supply is procured from trusted vendors who manufacture them using cutting edge technology and superior grade material and components. The Dust Collector is suitable to catch most types of dust particles efficiently. We supply durable and quality tested Dust Collector at affordable prices. Highlights Low operating costs resulting from cleanable long life filter cartridges Mobility combined with high extraction performance Tilt-back filter housings for easy dust disposal Optional test certificate for specialized applications

Cyclonic Dust Collector

Get Price Quote

1 Container (MOQ)

Filter Bag Cage

Get Price Quote

We are involved in offering an extensive range of Stainless Steel Filter Bag Cage. These cages are widely used in the major air pollution control systems. Manufactured using the controlled welding machines, these cages are assured of the topmost quality. Provided with galvanized electroplating, the range of filter bag cages offered by us is highly resistant to corrosion.

Dust Collectors

30,000 - 250,000 Per unit

1 Set (MOQ)

Bag Filters

11,000 - 21,000 Per Nos

1 Piece (MOQ)

Polyurethane Hydrocyclone

2,000 Per Piece