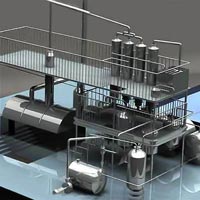

Cod Oil manufacturing plant

450,000 Per piece

Fish oil is taken from the flesh of various small, cold-water fish, such as mackerel, sardines and herring and even krill or algae oils. Whereas, cod liver oil is extracted from you guessed it the livers of cod fish. Fresh cod livers are digested by steam, water, acid, or alkali to produce the oil. Medicinal grades are chilled, and congealed stearic acid and other fatty acids are filtered off.

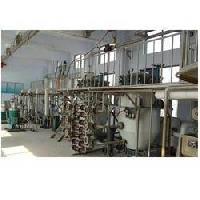

Edible Oil Refinery Plant

Get Price Quote

Best Deals from Edible Oil Plant

Edible Oil Refinery Plant

2,000,000 Per Piece

edible oil plants

30,000,000 Per Piece

Edible Oil Refinery - Plant & Equipment

Get Price Quote

1 Piece(s) (MOQ)

Edible Oil is An Important Primary Food and Requires Highest Degree of Product Quality. the Final Product Quality Depends On the Refining Method and the Nature of the Raw Oil. Fenix® Offers a Wide Range of Solutions Designed to Boost Value in this Respect. the Crude Oils are De-gummed and the Free Fatty Acids are Then Removed By Distillation in One Stage During Deodorizing. (some Oils like Cottonseed Oil or Fish Oil are Not Suitable for Physical Refining.) the Oil Discharged from Expeller Presses Has Certain Solid Content or Gum, the Level Varying On the Oil Seed, Which Must Be Removed. for Easier Separation, the Solids are Wetted with Hot Water and Separated Along with Hydrated Phosphatides in the Decanter/clarifier. the Solids are Returned to the Press for Recovery of Adhering Oil. the Clarified Oil is Then Either Refined Directly or Dried Under Vacuum for Storage or Consumption. fenix® “centrimix” Process for De-gumming, Neutralising and Washing is Designed to Handle a Multitude of Oil Feed Stocks. It is Followed By the Fenix Flexibleach Process Which Reduces the Bleaching Earth Consumption By 20 to 30%. We also have a Newly Developed Technology - Fenix Flexibleach with Pre Filtration – Based On the Reuse of the Spent Bleaching Earth Without Removing It from the Filters. Once the Spent Earth is Reused in the Filter, It is Discharged and Evacuated. the Final Step in Refining is the Innovative Fenix Eco2flex Deodorisation. Its Efficient Scrubbing System Minimises Fatty Matter Carry Over and Water Pollution. Efficient Plug Flow “hivac Heat Exchangers” Enhances Economy. It is Flexibile to Process High Ffa Oils By Physical Refining and Gives Vary High Stripping Efficiency Due to the Use of Cross Flow Column. Control for Optimizing Tocopherol and Minimizing Trans Acid Generation is Built-in. the Mechanical “free End” Prevents Thermal Fatigues in Heating/cooling Tubes. the Efficient Design Ensures 100% Draining and Cleaning. It is a New, Fully Integrated and Compact Deodorising System Including the Concept of Steam Injection in Which Deaeration, Heat Exchanging, Heating/stripping, Cooling and Scrubbing Take Place in a Controlled Environment. the Process is the Result of a Continuous Effort Based On the Experience of More Than 300 Deodorising Plants. in a Nutshell Fenix Edible Oil Refining Gives Very Short Payback Period Due To: ● Superior Product Quality ● Minimum Hydrolysis & Low Loss of Oil ● Highest Level of Heat Recovery ● Reduced Utilities (stem, Diesel/power, Water, Chemicals) ● Reduced Installation Cost ● Reduced Maintenance Cost, Limited & Easy Maintenance ● Easy Supervision

Edible Oil Neutralization Plant

40,000,000 Per Plant

1 Plant (MOQ)

Edible Oil Bleaching Plants

6,000,000 Per Plant

1 Plant (MOQ)

Edible Oil Refinery Plant

Get Price Quote

We provide Edible Oil Refinery Plant that is based on modern technology to refine a variety of edible oils. We design & supply customized edible oil plants as per local conditions and quality of oil. We manufacture all the equipment using modern manufacturing facility, which is ISO 9001-2008 certified by International Accredited Agency and export these plants on a turnkey basis. Our Plants are Highly Energy Efficient, low processing cost and deliver best quality Refined Oil. We are specially known as leading Rice Bran Oil Plant Suppliers, for providing plants that produces quality refined Rice Bran Oil. BRISSUN PLANTS ADVANTAGES : Maximum reduction of FFA and colorCustomised & latest technologyLow Consumption of UtilitiesLower Maintenance CostBland Oil with Maximum Shelf LifeRefined Oil Accepted by Most Multinationals Suitable For Refining : Rice bran oilSunflower OilMustard OilRapeseed OilSoybean OilCotton Seed OilPalm oil Refining by : DegummingBleachingDe-waxingDeodorizationFractionation Capacity : 25 TPD - 500 Tons per day

Edible Oil Refining Plant

Get Price Quote

We are offering edible oil refining plant.

edible oil plants

Get Price Quote

edible oil plants, edible oil machinery

Edible Oil Refining Plant

Get Price Quote

Edible Oil Refining Plant

Edible Oil Refining Plant

Get Price Quote

Edible Oil Refining Plant, Dining Chair, Single Bed, Bunk Beds