Vertical Ribbon Blender

Get Price Quote

In order to produce quality products, we make use of superior grade raw materials. Our quality auditors strictly check the raw materials against varied quality parameters before procurement. Our streamlined inventory system and capacious warehouse assist us in meeting the bulk requirements of the customers. Also, we ensure year round availability of the products. Features: High-performance Robust construction Easy operations & maintenance

Stainless Steel Powder Blender

300,000 Per Piece

1 Piece (MOQ)

Best Deals from Electrical Kitchen Appliance

blenders

Get Price Quote

We manufacture blenders using premium grades of stainless steel and alloy steel, our range of vessel and ribbon blenders are one of the most mixing common devices used in process industries. These ribbon blenders comprise helical ribbon shaped blades that rotate close to the edge of a U-shaped vessel that makes them applicable for high viscosity fluids and dry blends.

Conical Blender

Get Price Quote

To protect our entire range of products from external factors that can be damaging, we have a state-of-the-art packaging unit equipped with the latest secure packaging technologies and materials. Over the years, we have become a primary choice of the buyers sine our product is qualitative and deliveries are time bound. Applications: Crystallisation Cooling or heating Addition / spraying of liquids into material Mixing and homogenisation of powders, pastes and slurries Granulation or agglomeration of powders by the addition of a binder liquid Features : Minimum heat generation Volumes range from 5 - 6000 litres Self emptying with minimum product retention Fast mixing times with a high degree of mixing accuracy Gentle action on the product through low power consumption

Drum Water Tube Boiler

Get Price Quote

Rakhoh enterprises is one of the leading manufacturers and suppliers of drum water tube boiler. We have an expertise in the domain of manufacturing of drum water tube boiler, owing to our 17 years of experience. We design our product as per the latest amendments of the ibr code and other internationally recognized codes and are provided with more than all mandatory safety requirements. Suitable to burn different type of fuels : bagassehuskwood chipsbricketscoal benefits : less refractory work, hence less maintenance.high overall efficiency combined with reliable operation achieved through accurate computerized thermal and mechanical designs of boiler.provided with grates like fixed grate/dumping grate/pulsating grate/travelling grate/fbc grates.quick steam generation and can take care of changing requirement of the steam in the process.provided with accessories like super heater, economizer, air pre-heater, de-aerator tank, multi cyclone dust collector etc. As per requirement for better performance of the boiler.longer life of super heater as it is placed behind screen tubes in the furnace.multi-passes in convection bank make the boiler efficient and more economical.

Industrial Blender

Get Price Quote

We are instrumental in manufacturing, supplying and trading a qualitative array of Industrial Blender. Manufactured using high quality material, our range is applauded for its longer service life, noise free operations and sturdy construction. Furthermore, clients can avail these products from us in various specifications at Competitive rates. Features:• Noise free operation• Robustness• Longer service life

Octagonal Blender

Get Price Quote

We offer octagonal blender, ribbon blender.

Ribbon Blender

Get Price Quote

Working principle & features render’s ribbon blenders is design to provide high mixing efficiency, blending small proportions into large stocks. Ribbon blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced. A wide variety of configurations, for either batch or continuous mixing, are available. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing efficiency. Efficient mixing also provides good heat transfer through optional asme code designed jackets for heating or cooling applications. The compact and robust construction dust proof operation ensures their negligible running costs. We can offer these in various customized sizes/finishes. we provide custom made size design of the ribbon blender to meet your specific mixing requirements. Mixing vessels can be standard u-shape or cylindrical depending on internal pressure or vacuum requirements. Material finishes available ranging are from industrial coatings to dairy grade polishes.

Blender

Get Price Quote

Blender

Get Price Quote

We offer different type of Blender Ribbon Blender "U" type Ribbon Blender "O" type Conical Ribbon Blender Advantage : General mixing action with minimum power Optimum mixing time Accurate mixing & with minimum to zero retention

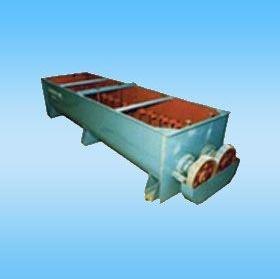

Horizontal Ribbon Blender

Get Price Quote

Horizontal ribbon Blender is widely used in chemical, pharmaceuticals, food, and construction line. It can be used to mix powder with powder, powder with liquid, and powder with granule. Under the driven of motor, the double ribbon agitator mix the material quickly. This ribbon mixer is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customer should choose the model according to the output per batch. Technical Parameter: Capacity: 25KG to 2000KG Mixing time: 30-60minspower: 0.7 5 KW-23 KW (varies as per capacity) Material: 316L, 304, 304L, Mild Steel Features - Blending with low RPM- Both Side walls are Sealed- Four Bearing Construction - Liquid Addition arrangemen Working Principle Blender consists of transmission parts, double ribbon agitators and U-shape cylinder. In the direction of rotation, the outer ribbon pushes materials from both ends to the middle, while the inner ribbon pushes materials from the middle to both ends. Ribbon wind with different angle direction carries the materials flowing in different directions. Through continuous convective circulation, the materials are sheared and mixed thoroughly and quickly. Applications - Chemical- Food- Pharmaceutical- Fertilizer- Plastic- Animal Feed- Cosmetic

PLASTIC MIXER GRINDER

Get Price Quote

Plastic is component of various products like HDPE, LDPE etc. Plastic trays , strips and purging s also give rise to plastic scrap. To recycle this plastic waste, a good mixer grinder is required . We,L.G. ENGINEERS manufacture and supply mixer and grinder. For plastic material with compact design and easy operations. Our plastic grinders are widely used in qualitative measurement of components in various industries . They are resistant to corrosion and they are highly efficient

Ribbon Blenders

Get Price Quote

Ribbon Blenders are best suited for mixing, granulation and homogenizing batch process. It handles a range of applications from all types of powders including free flowing to cohesive and moist powders, bulk dry materials to wet cakes and slurries. Ribbon Blenders are very sturdy and robust. They consists of a conical Vessel with dished / flat head. The central agitator shaft is driven from top end with gear reducer. A double helical ribbon agitator in the vessel moves the product upward along the outer wall and releases it downward into cavities developed in the middle, simultaneously material is horizontally distributed by the mixing arm and is optimally homogenized. Mixing time is depending on the agitator speed. In general mixing time is three to four times shorter than the mixers working with a rotating screw. The drive and bearings are kept outside of the vessel, no gears or seals in the product compartment. The rotating central agitator shaft does not have bottom bearing support there by eliminating any dead spots or difficult areas to clean and there is no danger of product contamination. Discharge of the product is fast and simple as full bore open. Design Options : • Models with single or double helix. • Net capacities for 20 to 25000 litres. • IVarious Material and surface treatment available depending upon product characteristics • Cutting rotors for breaking down of agglomerates • Liquid adding by ISP system. • Heating Cooling jackets with insulation

Ribbon Blenders

Get Price Quote

Excel Project , Ribbon Blender are mostly used by Chemicals, Plastic, Pharmaceutical, Paints and food industries. The Ribbon Blender does homogenous mixing of powder and semi-wet material of different densities. The ribbon blades of different designs are used to suit the need of different materials. The Blender consists of a Semi-cylindrical shell inside which rotates a Shaft fitted with spiral inner and outer ribbons.

Ribbon Blender

150,000 - 200,000 Per Piece

Screw Blenders

Get Price Quote

Our Screw Blenders are widely used by the clients as their blending action is gentler than any other horizontal blenders. These require low power as the active blending volume is less in comparison to that of the horizontal blenders. Blending depends on the variegated travel speeds of product particles in the conical section of the vessel. The screw collects the material from the bottom section of the vessel and spreads it over the upper sections.

Ribbon Blender

300,000 Per Piece

1 Piece (MOQ)

Countertop Dishwasher

71,550 Per Piece

1 Piece(s) (MOQ)

Hot Water Boiler

500,000 Per Piece

1 Piece (MOQ)

electric blender

Get Price Quote

Capacity 3. Blendor available in different capacity 25kg, 50kg, 60kg, 75kg, 100kg, 200kg, 500kg, 1000kg etc. Power Requirement 230V AC 1 Phase, (up to 75 kg capacity) 420 V AC 3 phase (from 100 kg & above)

Multi Gas Blender

150,000 Per Piece

10 Piece (MOQ)

Our expansive product line permits you to select the right gas blending for every application. Accurate to within +/- 1 percent of the selected ratio, of up to 8 gases in single blender . We subject them to the highest, most exacting quality control regimen in the flow controlling system.Industries full system integration provides automatic ratio setting of the gases and single output for the blended gases.Values : Accuracy, dependability, versatility, safety, and professionalism are our core values. The accuracy of our instruments is paramount to our mission . To this end, we manufacture or procure every part used in our devices and subject each component to the strictest quality control. We established a rigid quality assurance auditing schedule to ensure we meet that mark at every point in our production process.

Portable Electrode Drying Oven

3,050 - 4,500 Per Piece

1 Piece (MOQ)

gravimetric blender

600,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

Get Price Quote

We are the leading manufacturer and supplier of Ribbon Blender. While conveying to the center of the mixer drum, material goes through upward and downward movements. In order to control or vary the temperature of the masses, we offer a wide range accessories like liquid spray system, controlled rate discharge device and jackets. Features: Higher performance Longer functional life Strong in construction

SMP Power Blender

265,000 Per Piece

1 Piece (MOQ)

Conical Blender

Get Price Quote

The Nauta Mixer has a conical container which houses a constant flight screw.This screw revolves on its own axis and also around the cone wall.Material of diverse shape, size and densities are homogenously mixed without any deprivation. Application : • Dry Blending, Dry Blending with Liquid Spray. • Features: • Low Power Consumption • Short Mixing Time • Low space require • Gentle mixing action

Electric Ovens

Get Price Quote

We are entrusted with a task of providing Electric Ovens in the global market. The entire range is designed and developed in line with industry standards. We also make them available in different grades to meet unique and specific requirements. Renowned for their Easy function, reliable operation and low power consumptions, our Electric Ovens are of unmatched standards. Buyers can approach us for acquiring commercial electric ovens in temperature ranges. Highlights : High durability Tensile strength More about Electric Ovens The Ovens are double walled and made of SS 304 or as per customer's requirement. Insulated double walled metallic doors fitted with standard set of hardware with adjustable mesh. Belt Drive Motor Blower are Provided to maintain the temperature uniformly within the chamber. The Ovens are Durable, best performance & Low Maintenance. Imported Burners like Benton USA, ecoflame for Italy are used. Features : Transfer Mechanism : Conveyor Chain with slat/ A2/K2 attachments’, Honeycomb chains Semi-continuous, indexing type design Electrically /OIL/ Gas Heated Re-circulation Fans to ensure temperature uniformity better than +/- 5 degree C Torque limiters for safety. Pneumatically Operated chain tensioner PLC controlled. Capacity : 100 kgs / hour to 2000 kgs / hour.

Industrial Mixer Blender

100,000 Per 500 Litre

Conical Blender

425,000 Per Piece

Industrial Powder Blender

Get Price Quote

To mix dry powder & granules, these Industrial Powder Blender are considered very suitable and effective. These cone blenders are extensively used for cosmetic powder, food, chemicals. It is an efficient and versatile machine used for mixing powder and granules homogeneously. All the contact parts of the blender are made from materials with grades as required by customers. Our blender offers uniform mixing and easy discharge of material.