esd wrist straps

48 - 55 Per piece

200 pieces (MOQ)

Product Details: Color Blue Size 4 x 2.5 x 1.2 cm Resistance 10e12 ohm SD Wrist Bands is specially designed for use as a safety device in the electronic and electrical industry where sensitive equipment is used. This band is used for protecting the workers and sensitive equipment from electrostatic discharge.This band works by channeling static electricity to a proper ground. It is wisely designed using fine conductive fibers, made of carbon or carbon-filled rubber with a stainless steel clasp or plate. Features: One size fits all sizes of wrists Insulating outer surface Stainless steel inner surface Hypoallergenic Allows the skin to breathe and makes it very comfortable to wear Ground clip for easy contact to any electrical ground Rinsing resisting. Usage Areas: Electronic industry Electrical part manufacturing industry Telecommunication industry Electrical laboratories Semiconductor industry. Application: Prevent electrostatic discharge (ESD) in dry environment Prevent static charge from damaging electronic parts and equipment Used by workers working in an area where a grounding cable can get in the way Useful in an operating theater, where oxygen or explosive anesthetic gasses are used.

Digital Analog Intergration

Get Price Quote

Best Deals from Electronic Circuit Boards

Spacers

Get Price Quote

We are Offering Various Types of Spacers and Washers are Manufactured as per Customer Requirement

EMI Shielding Glass

Get Price Quote

Cutting and Brushing Machine

Get Price Quote

We manufacture high-end Cutting and Brushing Machine, which is strongly built and has an adjustable degree scale (20-200). Made up of the finest grade material and cutting-edge technology, our products have seamless quality. As we know the value of quality raw materials, we source them only from dependable vendors. By applying such inputs, we make sure that our finished goods remain flawless.

pcb chemicals

Get Price Quote

Cutting and Brushing Machine

Get Price Quote

Made up of the finest grade material and cutting-edge technology, our products have seamless quality. As we know the value of quality raw materials, we source them only from dependable vendors. By applying such inputs, we make sure that our finished goods remain flawless.

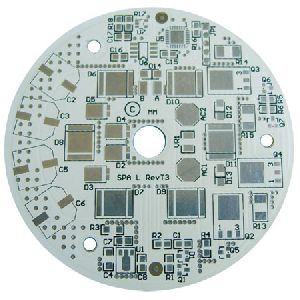

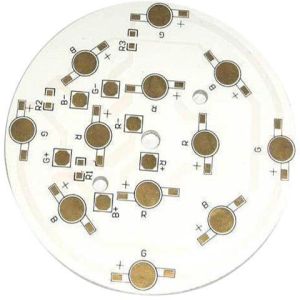

Aluminium PCB Circuit Board

Get Price Quote

Diya Electronics has been producing Aluminum Printed Circuit Boards (also called Metal base PCB). Although, originally envisioned for use in the power-supply industry these substrates are now most widely used in High Brightness LED products. There are many names for these products; Aluminum clad, Aluminum base, Metal clad (MCPCB), Insulated Metal Substrate (IMS or IMPCB), thermally conductive PCB, etc. but they all mean the same thing.Aluminum PCB is a unique metal-based copper clad laminate; it has good thermal conductivity, electrical insulation and machining performance. Aluminum PCB market mostly Fuchs Wright aluminum substrate. Common in the LED lighting products.Aluminum PCB is one of metal-based pcb, including copper foil, thermal insulating layer and metal substrate, its structure divide into three layers :• Circuit layer: the equivalent of an ordinary PCB, copper thickness from 1oz to 10oz.• Insulation layer: Insulation is a layer of thermal insulating material with low thermal resistance. Thickness: 0.003 "to 0.006" inch is the aluminum pcb core technology.• Based Layer: a metal substrate, usually aluminum or copper may be chosen. The heat dissipation afforded by this construction is dramatically superior to standard FR-4 constructions. The dielectrics used are typically 5 to 10 times as thermally conductive as conventional epoxy-glass and a tenth of the thickness resulting in thermal transfer exponentially more efficient than a conventional rigid PCB.Although Power Converters and LEDs are the largest users of these products, Automotive and RF companies are also looking to take advantage of the benefits of these constructions. A single layer construction is the simplest, most thermally conductive and most cost effective construction. Designs with higher component counts may not have room for all the required routing on a single layer. In this case a two layer design is required. A thin sheet of dielectric, typically around .006” thick, is drilled, plated and etched much like a standard double sided printed circuit board. The sheet is then laminated using thermally conductive bonding material to the metal base. This extra routing layer results in components farther away from the heat-sink and reduced heat transfer so this construction is recommended only when necessary.

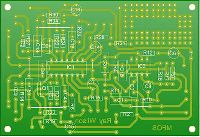

Single PCB

Get Price Quote

Single pcb, Single sided PCB’S have been around since the late 1950s and still dominate the world market in sheer piece volume. Single-sided printed circuit boards are easily designed and quickly manufactured. They serve as the most cost effective platform in the industry.

aluminium pcb

0 Per Square Centimeter

Pcb Cutting Machine

Get Price Quote

Pcb Cutting Machine, Conveyor Belt Cutting Machine, Automatic Cutting Machine

ccd board camera

Get Price Quote

ccd board camera

Printed Circuit Boards

Get Price Quote

We are offering printed circuit boards. 1 single sided pcb 2 double sided pcb 3 mcpcb.

Spacers

Get Price Quote

Spacers, gear kick starter, Bulkhead Connector, Female Pipe Connector

Inverters

Get Price Quote

Inverters, Uninterruptible Power Supply, Generators, Power Supply

Electrical Antistatic Tray

Get Price Quote

Electrical Antistatic Tray, vacuum forming tray, Vacuum Formed Hip Tray

Inverters

Get Price Quote

Inverters, Batteries, dry cells, Ups, Battery Maintenance Services

PCB Assembly

Get Price Quote

steel security shutter doors

Get Price Quote

steel security shutter doors, Hand Operated Rolling Shutter

Circuit Boards

Get Price Quote

Circuit Boards