ZNC EDM

Features Incorporates PS-50 ZNC Pulse Generator 99 programmes, 50 steps per programme EDM technology at a glance on CRT 3 axes digital positioning display Day and night function Reverse servo machining Higher Material Removal Rate due to equi-energy pulse Reduced electrode wear with high MRR High speed jump function (Speed up) Built-in super finish function Fuzzy Features Automatic selection of optimum EDM parameters Online 'HELP' to guide the operator in parameter selection Adaptive anti-arc which monitors the gap conditions for every pulse and adjusts the EDM parameters to suit the gap conditions

...more

Yota- Die Casting Machine

Dry Shot Injection Speed 7msec PLC based control CNC Control Digital Hydraulics Range 100T - 800T Capacity

...more

Wirecut EDM

FeaturesPrecision LM Guides for X, Y, u, v, Z axes Cutting speed : 120 mm2/min Best surface finish 0.8µ Ra Taper : ±15° over 100mm Hand-held remote control Dielectric cooling with differential temp. control ePulse technology CNC Pulse Generator ELPULS - 20e15�VGA colour graphics CRT display Display of cutting rate Display of machining time 2D graphic simulation of wire path Display of error messages Different screen for MDI programming Simultaneous control of X, Y, u, v axes MOSFET for high speed switching and better surface finish Trim cut facility for improved accuracy Dual state antiarc circuitry leading to feed hold Mirror image of programme across XY axes Rotation of programme by 90° Single block execution Resumption of cutting from power fail position Finer controls in steps of 0.5µ sec. for optimizing ON/OFF time Memory data retention period-48 hours e Pulse AdvantagesStable machining without wire breakages normally occurring in difficult machining conditions such as, Flushing nozzle away from work piece Stacked work pieces of different materials Cutting at the edge of work piece etc. Higher cutting speed even on smaller work piece thickness Minimum operator intervention User-friendly, versatile Software ELAPT : DXF file interface Built-in utility packages for gears and curves Graphic programming tool Built-in functions : move, rotate, copy, mirror, scale, reverse mirror Multicut programme generation Tool path reversal for multicut Graphical simulation of NC programme RS 274 standard G /M code programme generation with powerful editor Technical SpecificationsMachine ToolMax. table size : 650 X 440 mm Max. work piece height : 200 mm Max. work piece weight : 300 kg X, Y table traverse : 300, 400 mm u, v table traverse : 80, 80 mm Max. wire spool capacity : 6 kg Max. taper angle : ± 15°/ 100 mm Resolution : 0.001 mm Wire electrode dia. : 0.25 mm (Std.) 0.15. 0.2, 0.3 mm (optional) Pulse Generator : ELPULS - 20 e Controlled axes : X, Y, u, v simultaneous Interpolation : Linear & Circular Least input increment : 0.001 mm Least command input (X,Y) : 0.001 mm Max. programmable dim. (X,Y) : ± 999.999 Data Input / Output : �RS-232C isolated serial interface, �1.44 MB Floppy disk, �Special function sealed keyboard Input power supply : 3-phase, AC 415 V** 50 Hz Connected load : 7 kVA Dielectric unit DL 25P Dielectric fluid : De-ionised water Dielectric tank capacity : 250 lit. Paper filter : 10 µ Single cartridge Dielectric cooling system : 1700kCal.

...more

Vertical Turret Milling

We are offering vertical turret milling. x - 500 x 600 mm y - 300 x 400 mm rapid x y z - 48m tool - to -tool time - 0.9 secs

...more

turret punch press

CNC Hydraulic turret punch presses CNC Servo drive turret punch presses Turret punch press with Right Angle shears TPP with laser machines Auto sheet loading and unloading systems for TPP and Lasers Auto sheet bending cells Laser cutting machines Servo Drive Press Brakes.

...more

Tough Carb Division

The Tough Carb Division is part of Electronica Machine Tools Pvt Ltd . It Manufactures Tungsten Metal Powders, Tungsten Carbide Powders and Mixed Powders. The Tough Carb Division manufacturing facility is located at Sinnar, Nashik in West Maharashtra. This is an integrated plant with the starting material being Tungsten Ore, which is processed to APT and further processed to WC powders. The plant is equipped with modern machines and also has Spray dryer (Niro make). Some of the speciality products manufactured are Tungsten Metal Powder upto 0.4 µm FSSS, Nickel Bonded Carbide grades for Seal Rings, etc.

...more

Surface Grinder

More than 200 installations in IndiaCross x Longitudinal travel - 210 to 1900 x 475 to 6150 mm

...more

Sprintcut

FeaturesMachine ToolPrecision LM guideways for all 5 axes (X,Y,u,v,Z) Integrated u, v axes having stroke 80 x 80 mm Semi-automatic wire feeding with chopper New e Pulse technologyThe product of extensive R & D, features two characteristics. Equi-energy pulsei.e. all sparkingpulses carry equal energyAdaptive to the gap conditionsi.e. pulse will correct itself to gap conditions e Pulse AdvantageStable machining without wire breakages normally occurring in difficult machining conditions such as, Flushing nozzle away from the workpiece - Stacked workpieces of different materials - Cutting at the edge of work piece etc. Higher cutting speed even on smaller work piece thickness Minimum operator intervention NC Functions of ELPULS 40A6 work co-ordinate system Auto reference point return Auto wire verticality, edge finding & centre finding On line edit facility & directory option Mirror image of programme across X Y axes Rotation of programme Single block execution Corner control strategy to enhance shape accuracy Monitoring of consumables On-screen maintenance check Wire diameter compensation on contour Backlash compensation Pitch error compensation EDM machining parameter override Pre-spark function No man function Servo SystemQuick response close loop DCServo System for X, Y, u, v with PWM Servo Drive Part Programming Software - ELAPT Menu driven graphic programming CAD tool Comprehensive geometry definition Transformations In-bult functions : move, rotate, copy, mirror, reverse mirror and scale Multi-cut programme generation Tool path reversal Utilities for gears generation and curve fitting Powerful editing DXF interface Off-line ELAPT Standard scope of supplyMachine tool CNC Pulse generator ELPULS-40A Dielectric unit DL 25P Dielectric cooling system Standard accessories consisting

...more

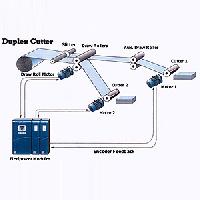

simplex duplex rotary cutter

In paper conversion, finishing& printed film processing, material has to be cut to required preset lengths, with accuracy and repeatability. A typical system comprises of a draw roller and one or two rotary cutters which are synchronized with the draw rollers to give the desired cut length.Application requirementsVariable length setting Accuracy and consistency Minimum setting time High speed operation Simple to operate FeaturesZero setting timel Excellent accuracy & repeatability Negligible paper wastage Energy efficient Maintenance free Programmable length setting Eliminates PIV gear boxes, prone to maintenance Cutting with registration mark Application SolutionTwo separate AC Induction motors are used. One motor is coupled to the draw roller and another is coupled to the rotary cutter. The operator sets the line speed which decides the draw roller RPM. The Rottary Cutter is electronically geared with the draw roller. The Rotary Cutter exactly follows the draw roller with a set ration. The ratio remains undisturbed during acceleration. This feature is called the zero backlash electronic gearing, with programmable gear ratio. This close loop control system measures sheet length accuracy at every cut. The number of controlled motors depends on the application, as well as either simplex or duplex.

...more

rotary printing

This application is normally used in paper printing, textile printing or synchronization is the need of the application. Separate motors are used to control individual rollers.Application requirements Precise registration sensing and synchronization Multicolour printing Tension control Accuracy in printing FeaturesPrecise position synchronization of individual rolls Registration mark sensing Higher line speed Encoder feedback for dancerless tension control Built-in PLC for process interlocks Elimination on unwinder brake User friendly man-machine interface Application SolutionIn the scheme offered the draw roller is preciesly controlled by a vector controlled AC induction motor or by a servo motor. Precise position control is achieved through encoder feedback. Build-in PLC I/O's are provided for syncronized process operation and saftey interlocks.

...more

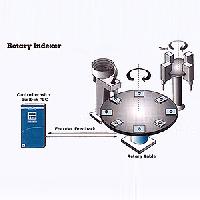

Rotary Indexer

This is a typical rotary table indexing type application, where it is required to index the table in angular control or conveyer in packaging and Pharmaceutical Industry.Application requirementsAngular programming Holding torque at zero speed Synchronized operations mooth acceleration an deceleration FeaturesProgrammable acceleration and deceleration. Angular degree programming Programmable software cam switches Sequencing of operations through bult-in PLC User friendly operator interface limination of complicated mechanical parts Application SolutionWe offer a standard AC induction motor with a vector controlled drive and a DSP based motion controller for this application. The encoder mounted on the rotary table gives 10,000 pulses per revolution and it is possible to rotate the table by 0.036 degree. A holding torque delivered by the motor at zero speed allows to eliminate Geneva type mechanical arrangements. The resolution can be increased by selecting different encoder.

...more

roller flow forming machine

Electronica has been manufacturing highest quality machines for more than 30 years. These machines, required in Tool Rooms and for production, are proving their worth at thousands ofinstallations in India & Overseas. Now Electronica proudly presents its latest achievement in technology - a CNC, 2-Roller Flow Forming Machine for manufacturing metallic conical liners.It is the first time that such an innovative-technology machine is being manufactured indigenously. This novel CNC machine has electro-mechanical design, vector control drives and AC induction motors for the spindle and axes. The machine, ideal for non-cutting shaping and forming, does not make use of any hydraulic systems.The robust, ergonomically designed, state-of-the-art machine offers a unique solution for conical liner forming. It assures precision, consistency, flexibility and productivity.

...more

Proth Surface Grinder

Cross x Longitudinal travel : 210 to 1900 x 475 to 6150 mm

...more

plastic processing machine

HAITIAN Injection Moulding Machines ranging from 58 T to 530 T

...more

Optima Series

Clamping Unit Sturdy, five-point double toggle mechanismOpening & Closing in 4 stagesStrong, cast SGI platens & toggle linksLow pressure mold safety protectionLinear Transducer for the precise Clamp position Control Simple manual grease lubrication with “reminder”messageMulti-stroke ejection mechanism.Auto mold thickness adjustment with Auto Tonnage SettingHydraulic safety Injection Unit Nitrided Screw & BarrelInjection in 4 stagesHold-On in 2 separate stagesRefilling in 2 stagesDecompression before & after PlasticizingHigh Torque, Low Speed Direct Hydraulic screw driveCold-start prevention facilitySprue break facilityLinear Transducer for precise & consistent injection position control & monitoring. Standard Features Proportional HydraulicsErgonomically designed machine covers for safety, with improved aestheticsStress-relieved, strong & compact machine base frameHighly reliable Electrical & Electronic components from Reputed manufacturersErgonomically designed, easy to service Hydraulic circuit Standard Features of Controller5.7” LCD display (320 X 240 pixels).4-stage speed, pressure & position control for mold close open.Built-in mold safety.Multi-stage speed, pressure & position control for injection.2-Stage hold-on pressure control. 2-Stage speed, pressure & position control for refilling.Suck back before and after refilling.Linear transducers for mold and screw position.2-stage speed & pressure control for carriage forward.Auto purge facility.Auto mold height adjustment with auto tonnage setting facility.Cold start-up preventation.Multi-stroke ejection.Digital display of screw RPM for current auto cycle.Auto trip-off facility in case of motor overload.Preset production counter with auto trip-off facility in case 'Preset Production Count' is over.'Auto Screen Shut-Off" facility.Built-in, self-diagnostic functions and auto alarm facility in clear text.Settable timers and delays for various operations.Settable ramp settings for mold closeopen operations.Display of last cycle time.Possibility of 64 sets of "Mold Data Storage'Password interlocks for different operating levels with individual screen locking.Display of machine operation status at all the time.4 Sones for temperature control with 'PID' logic.Statistical process control through deviation monitoring alarms.Hour count for total machine & in each mode of operation.'SPC' trend curve to monitor critical process parameters.Hourly production data for last 20 days with date & time.Alarm log data for last 100 alarms with all details.

...more

Optima Height Master

Features:Zero setting at any point Switching over between two reference points (Two references with offset) mminch coversion Probe diameter compensation Measurement of groove width, edge & centre distance Measurement of inside & outside diameters with center distances and differences and difference between center distances.Measurement of squareness Motorised Auto Squareness with Digital Dial* Parallel-printer port Serial port for RS 232 C output Air bearing Memory-100 Steps Serial Port Cable User friendly console with AudioVisual indication.Basic Instrument consists of following standar accessories:Optima 350 - Ball Probe of diameter 4mm x length 55 mm, Setting Master, Adaptor, Operation Manual, Dustcover.Optima 600 - Ball Probe of diameter 10mm x length 55 mm, Setting Master, Adaptor, Operation Manual, Dustcover.Optima 1000 - Ball Probe of diameter 12mm x length 62 mm, Setting Master, Adaptor, Operation Manual, Dustcover.

...more

milling Machines

Table Sizes:225 x 1067 mm to 305 x 1270 mm

metal forming machine

Finn-Power-Turret Punch PressesCNC Hydraulic turret punch presses CNC Servo drive turret punch presses Turret punch press with Right Angle shears TPP with laser machines Auto sheet loading and unloading systems for TPP and Lasers Auto sheet bending cells Laser cutting machines Servo Drive Press Brakes

...more

Manual EDM

Machine ToolFixed table, moving column type machine tool X, Y guide ways fitted with turcite Z axis with LM guides Motorised X and Y axes DC servo motor for Z axis Drop door work tank X, Y, Z axes with linear scale (0.005 mm Resolution) 'L' shape filtration system with small footprint High performance PS series GeneratorReduction in power consumption Guaranteed lowest electrode wear with high MRR In-built 3 axes DRO with PSD (Pre-Set Depth) for Z axis Predictable performance Multistage anti-arc control Microcontroller based logic circuits and oscillator Hand-held machine control unit for ease of operation Safely interlocks with Audiovisual SignalInput supply Servo overload Over flow Auto positioning Low level Spark-guard Fan failure Over temperature Fire detection indication (Optional) Technical SpecificationsMachine Tool Work tank internal dimensions (WxDxH) : 1500 x 800 x 600 mm Work table dimension : 900 x 600 mm Longitudinal travel (X) : 600 mm motorised Transverse travel (Y) : 400 mm motorised Max. permitted load on table : 5000 kg Max. work piece height : 400 mm Quill travel (Z) : 400 mm Max. electrode weight 300 kg Servo system for Z axis : DC servo with ball screw Dielectric Unit : Tank capacity : 1800 ltrs. Filtration system : 10 µ Paper filter cartridges (6 Nos.)

...more

Magnetic Scales

Salient Features:Non contact High Speed Highly resistant to oil, dust, dirt, vibrations & shocks Compact and light weight Easy to install Wide mounting tolerance Length upto 30 meters Ideal for hostile environments.Application:Hydralic presses Textile machines Wood working machines Machine tools Rotary tables Sheet Metal working machines Bending machines Universal testing machines Packaging Machines Paper cutting machines Gear cutting machines Robotics Applications Automation Marking machines SPMS Plastic machines Jigs and Fixtures X, Y Tables Handling machines Inspection System and many more.

...more

Laserjet Cutting Machine

Realization of super high speed processing with flying optics methods. Realization of high productivity with auto pallet changer. Employing high capacity FANUC oscillator (optimum capacity fitted with the same company's NC Machine). Highly rigid casting structure frame.

...more

Laser Cutting Machine

Daewoo-Ilrim - Laser Cutting MachineRealization of super high speed processing with flying optics methods. Realization of high productivity with auto pallet changer. Employing high capacity FANUC oscillator (optimum capacity fitted with the same company's NC Machine). Highly rigid casting structure frame.

...more

Honor- Vertial Turret Lathe

CNC Vertical Lathes. High Precision, High Efficiency, High Durability and perfection. Range upto 1750 mm dia.

...more

Height Gauge

Height Gauge for the new MillenniumLM Guide technology Sylvac measuring system Long life bearing material Latest aesthetic concepts Operates on one 3V battery Ergonomic design.Features:The system is based on LM guide technology with aluminum alloy rail & special bnearing material. The unique gluing technique takes care of differential thermal expansion. Rigid construction ensures repeatable performance of height measurement. Power supply One 3V Lithium battery - Type CR 2032. Suitable for shop floor environment. Carbide tipped scriber. Battery life 2000 hours. Functions:Zero setting Data hold mm/ inch conversion Reference point Error message Error message height measurement Low battery message Dial holder ( optional ) RS 232 Data Output ( optional )

...more

Finance

Electronica Finance Limited.Commitment for brighter tomorrow Electronica Finance Limited (ELFL), incorporated in 1990, commenced its Financial activities, as an extension of the parent company to provide financial assistance to the buyers of their Machines. Steadily it converted its focus of financing to other standard Machine Tools too. We not only finance to the customers of our Machines but also have tie-ups with other standard Machine Tool Manufacturers in the country to provide financial assistance for their buyers.Today ELFL is registered with Reserve Bank of India as Equipment Leasing Company, prominently engaged in financing of standard Machines to the Small Scale Industry and Medium Scale Industry by way of Lease, Hire Purchase and Loans. Other activities: Bill Discounting, Funds Mobilization through SNCD, Fund Syndication and Advisory Services. We also provide L.C. facility to our customers for buying imported machinery.In addition we are the corporate agents of ICICI Prudential and ICICI Lombard for providing life and non life insurance services.Geographically it covers three zones in India viz West, South and North with branch network covering following areas :-

...more

Industrial Automation

Be first to Rate

Rate This